A kind of preparation method of ultra-thin graphene thermally conductive adhesive layer

A thermally conductive adhesive layer, graphene technology, applied in the direction of adhesives, pressure-sensitive films/sheets, non-polymer adhesive additives, etc. Poor weather resistance and other problems, to meet the needs of poor thermal conductivity and assembly, good adhesion and thermal conductivity, and ultra-thin physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

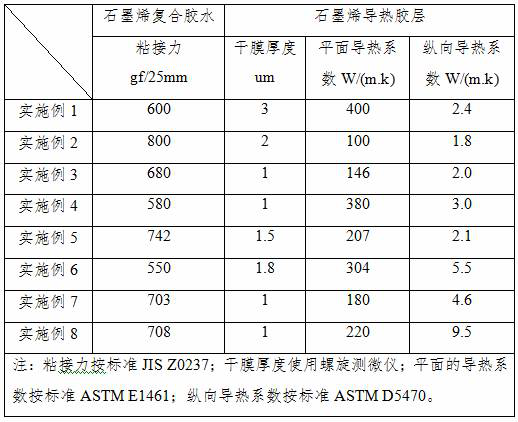

Embodiment 1

[0027] This embodiment proposes a method for preparing an ultra-thin graphene thermally conductive adhesive layer.

[0028] Prepared by the following steps:

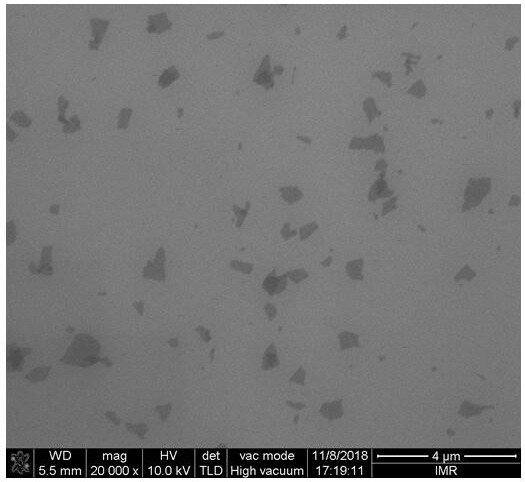

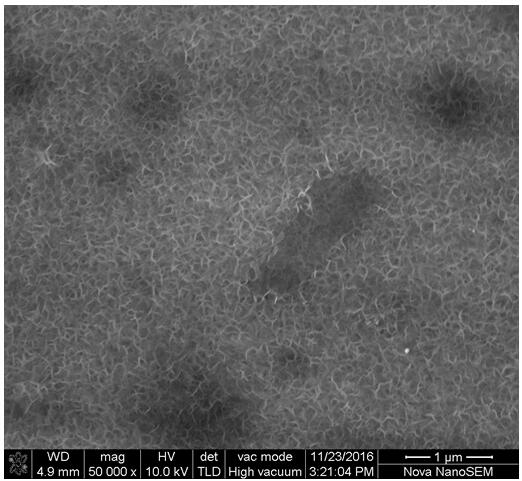

[0029] (1) Pretreatment: mechanical stripping or intercalation

[0030] (2) The graphene prepared by the method is used as the raw material, and the graphene satisfies: the carbon-to-oxygen ratio is 50, the number of layers is 8 layers, and the electrical conductivity is 550S / cm. According to the mass percentage, 3% graphene, 96.5% water and 0.5% The mixture of sodium lauryl sulfate and hexadecyl ammonium bromide is prepared into a graphene slurry, stirred by a stirrer for 10 hours, pre-emulsified for 10 hours, emulsified for 200 hours, and dried to obtain a sheet diameter of 460um graphene powder.

[0031] (2) Glue preparation:

[0032] In terms of parts by mass, 5 parts of the graphene powder and 59 parts of toluene prepared in step (1) were taken for ultrasonication or shearing to obtain a graphene / organic solvent ...

Embodiment 2

[0036] This embodiment proposes a method for preparing an ultra-thin graphene thermally conductive adhesive layer.

[0037] Prepared by the following steps:

[0038] (1) Pretreatment: Graphene prepared by mechanical exfoliation method is used as raw material. Graphene meets: carbon-to-oxygen ratio 45, number of layers 10, electrical conductivity 510S / cm, by mass percentage, 3% graphene, 96.5% After preparing the graphene slurry with water and 0.5% sodium dodecylbenzenesulfonate, it was stirred by a stirrer for 0.5h, pre-emulsified for 10h, emulsified for 1h, and dried to obtain graphite with a sheet diameter of 400nm. ene powder.

[0039] (2) Glue preparation:

[0040] In terms of parts by mass, 1 part of the graphene powder prepared in step (1) and 25 parts of ethyl acetate were subjected to ultrasonication to obtain a graphene / organic solvent dispersion.

[0041] In terms of parts by mass, 30 parts of graphene / organic solvent dispersion prepared by the above method and 40...

Embodiment 3

[0044] This embodiment proposes a method for preparing an ultra-thin graphene thermally conductive adhesive layer.

[0045] Prepared by the following steps:

[0046] (1) Pretreatment: Graphene prepared by mechanical exfoliation or intercalation method is used as raw material. Graphene satisfies: carbon-to-oxygen ratio 42, layer number 1 layer, conductivity 505S / cm, and 3% graphite by mass percentage Graphene, 96.5% water and 0.5% hexadecyl ammonium bromide are formulated into graphene slurry, stirred by a mixer for 5 hours, pre-emulsified for 3.5 hours, emulsified for 20 hours, and dried to obtain the size of the sheet. 300nm graphene powder.

[0047] (2) Glue preparation:

[0048] In parts by mass, 2 parts of the graphene powder prepared in step (1) and 35 parts of the mixture of ethyl acetate and xylene were subjected to ultrasonication or shearing to obtain a graphene / organic solvent dispersion.

[0049] In terms of parts by mass, 45 parts of graphene / organic solvent dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com