Pile-platform integrated formation construction technology

A construction technology and an integrated technology, which is applied in the direction of sheet pile wall, foundation structure engineering, construction, etc., can solve the problems that the quality of finished products with long construction period is affected by the technical level of personnel, weather, pile concrete breakage, pile position deviation, etc. , to achieve the effects of short construction period, reduced construction period and good quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

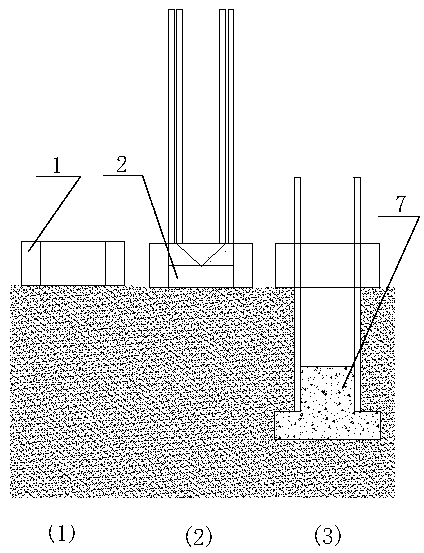

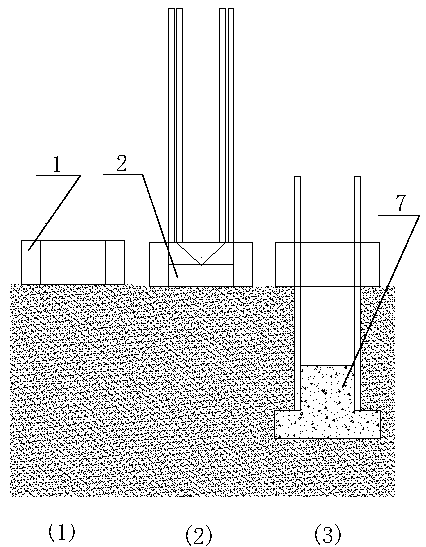

[0028] Such as Figure 1a-1b , image 3 As shown, a construction technique for integrally forming a pile abutment includes the following steps:

[0029] (1) Place the prefabricated cap pile position positioning device 1 to the position where piling is required, and the inner diameter of the through hole set in the axial direction of the cap pile position positioning device 1 is slightly larger than the outer diameter of the pile driver;

[0030] (2) Arrange the pile driver. The pile barrel of the pile driver is divided into an outer cylinder 3 and an inner cylinder 4. The outer cylinder is a hollow cylinder, and one end of the inner cylinder is provided with a tapered end; before piling, pour a certain amount into the gap between the inner and outer cylinders. A certain amount of water-sealing concrete 2 is used to seal groundwater from pouring into the pile barrel; the pile barrel works up and down along the vertical direction in the through hole of the cap pile position pos...

Embodiment 2

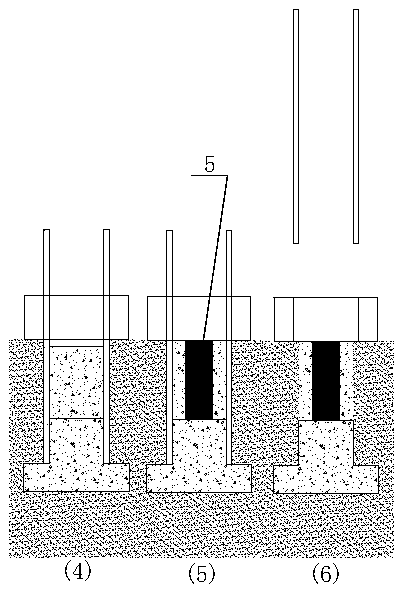

[0035] Such as Figure 2a-2b As shown, a construction technique for integrally forming a pile abutment includes the following steps:

[0036] (1) Place the prefabricated cap pile position positioning device 1 to the position where piling is required, and the inner diameter of the through hole set in the axial direction of the cap pile position positioning device 1 is slightly larger than the outer diameter of the pile driver;

[0037] (2) Arrange the pile driver. The pile barrel of the pile driver is divided into an outer cylinder 3 and an inner cylinder 4. The outer cylinder is a hollow cylinder, and one end of the inner cylinder is provided with a tapered end; before piling, pour into the gap between the inner and outer cylinders A certain amount of water-sealing concrete 2 is used to seal groundwater from pouring into the pile barrel; the pile barrel works up and down along the vertical direction in the through hole of the cap or cap pile position positioning device;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com