Integrated foundation with integrally formed pile platform

An integrated, pile-mounted technology, applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as insufficient cross-section strength, insufficient pile top strength, and affecting the bearing capacity of single piles, and achieve the effect of avoiding pile position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that the orientation words and the like described in this embodiment are all described according to the drawings, and do not constitute limitations on the present invention.

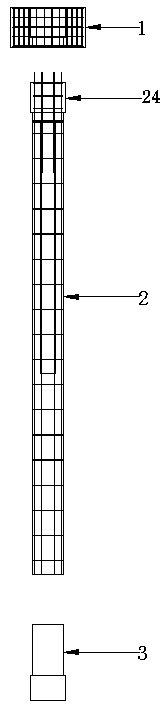

[0023] Attached below Figure 1-5 The present invention is described in further detail: as figure 1 As shown, an integrated foundation with integrally formed pile abutments includes a positioning member 1 , a pile body 2 and a pile bottom 3 .

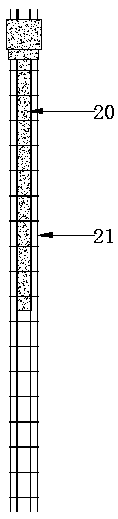

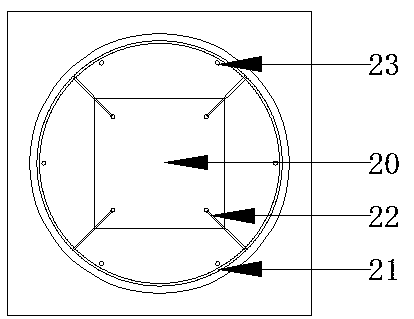

[0024] Such as figure 1 , Figure 2-3 As shown, the pile body 2 includes a prefabricated solid column structure 20, a reinforcement cage 21 and a boss 24; the prefabricated solid column structure 20 is a hexahedron, located at the center of the pile body, and is formed by pouring transverse reinforcement, longitudinal reinforcement and concrete; Reinforcement cage 21 is a cylindrical network structure composed of transverse reinforcement and longitudinal reinforcement, which surrounds the outer ring of prefabricated solid column struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com