High-performance sealing ring capable of achieving self-inspection after cracking

A sealing ring, high-performance technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of self-inspection sealing ring strength reduction, sealing ring fracture failure, affecting the normal operation of bearings, etc., to increase work performance, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

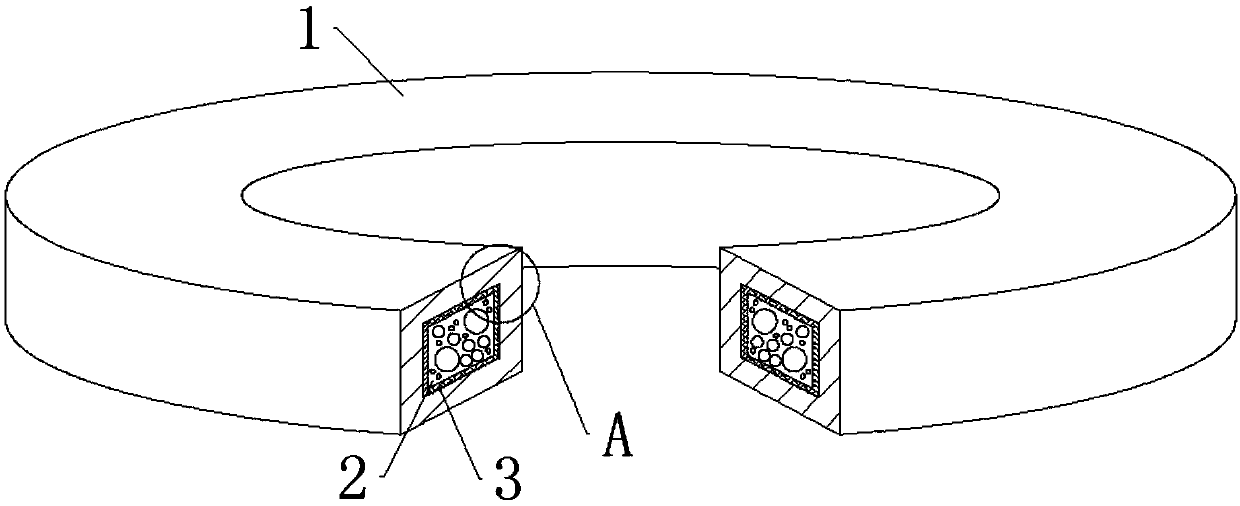

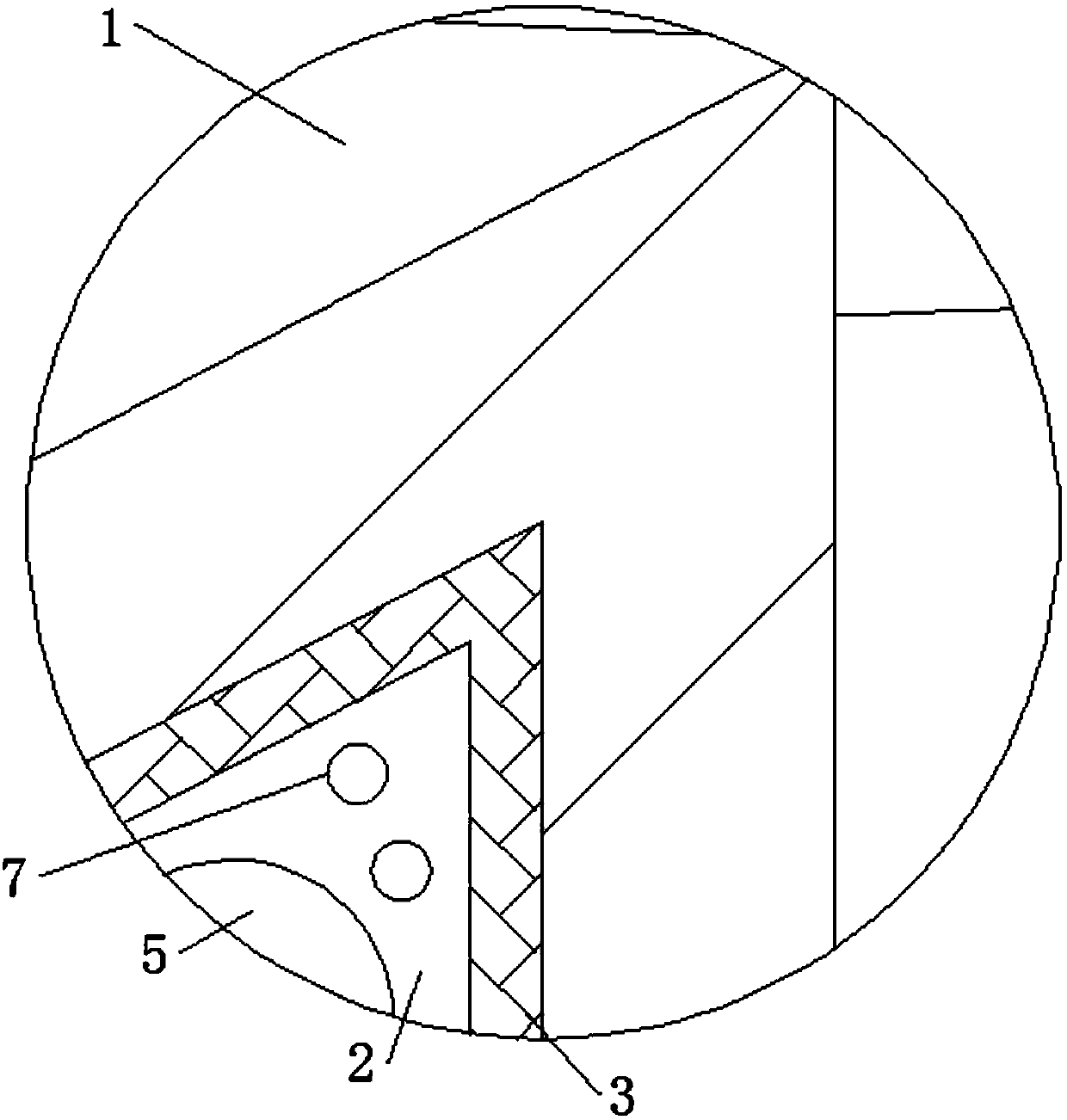

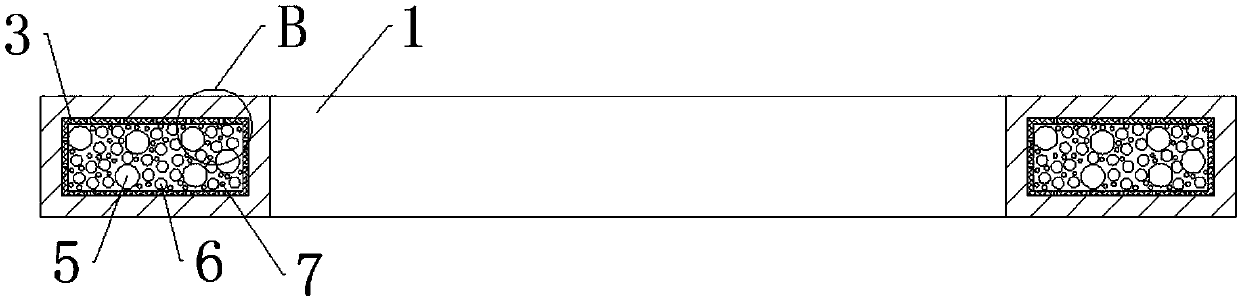

[0045] see figure 1 with image 3 , a high-performance sealing ring that can be cracked and self-inspected, a high-performance sealing ring that can be cracked and self-inspected, including a fluorosilicon rubber sealing ring 1, a sealing ring cavity 2 is dug in the fluorosilicon rubber sealing ring 1, and the sealing ring Cavity 2 is used to fill No. 1 ball 5, No. 2 ball 6, No. 3 ball 7 and liquid solvent, and nano-carbon skeleton 3 is arranged in sealing ring cavity 2, and the fixing of nano-carbon skeleton 3 and sealing ring cavity 2 Connection, the nano-carbon skeleton 3 is opened with a plurality of through holes 4, the nano-carbon skeleton 3 is the skeleton of the fluorosilicone rubber sealing ring 1, which is used to increase the strength of the fluorosilicone rubber sealing ring 1 and limit the deformation of the fluorosilicone rubber sealing ring 1 , while the through hole 4 allows the liquid solvent to flow through, and the No. 1 ball 5, the No. 2 ball 6 and the No....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap