A rust-proof and durable gate valve

A durable, gate valve technology, applied to valve devices, sliding valves, cleaning methods and appliances, etc., can solve problems such as inconvenient disassembly, easy blockage of filter nets, unusable gate valves, etc., to achieve convenient disassembly, improve stability, and improve practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

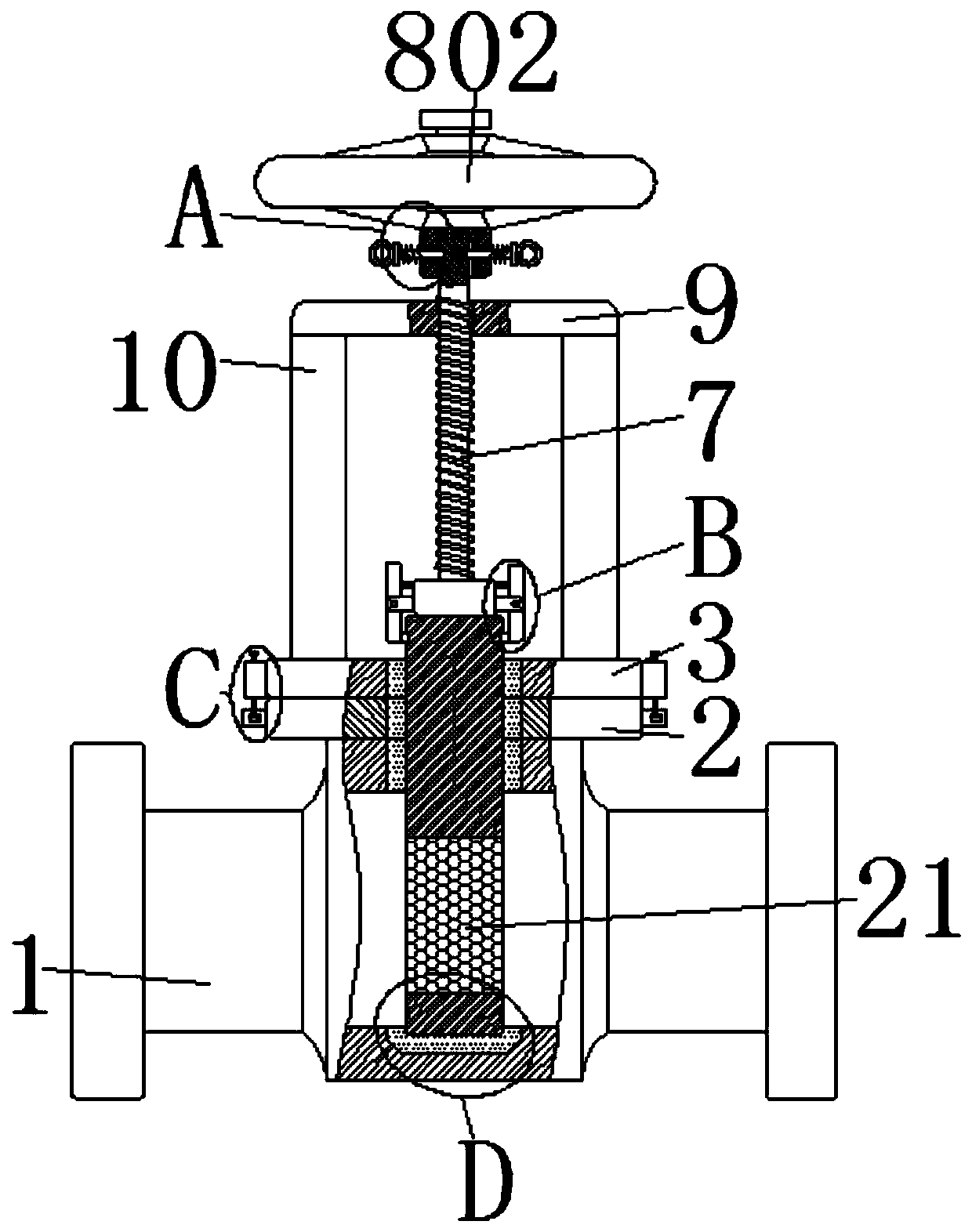

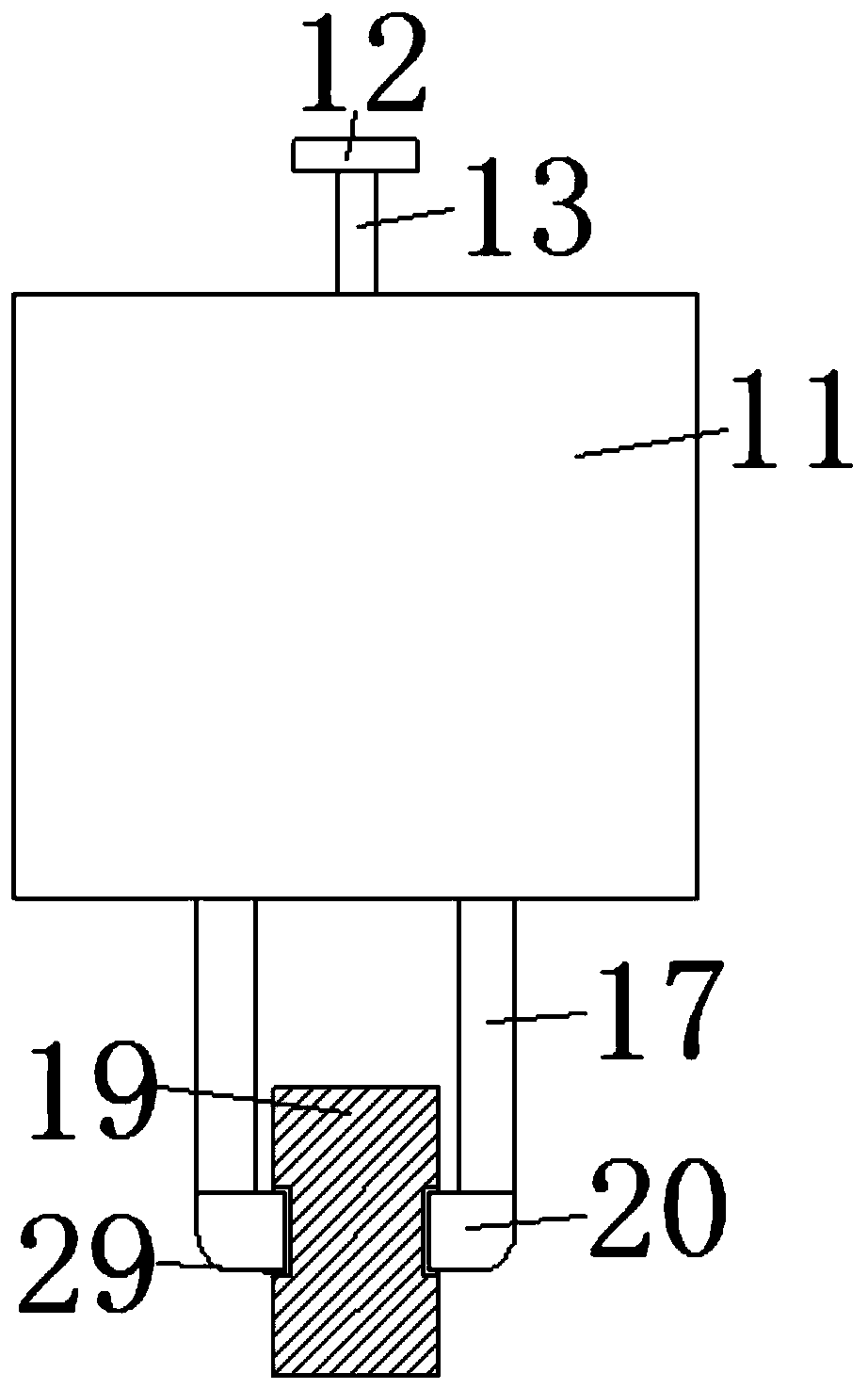

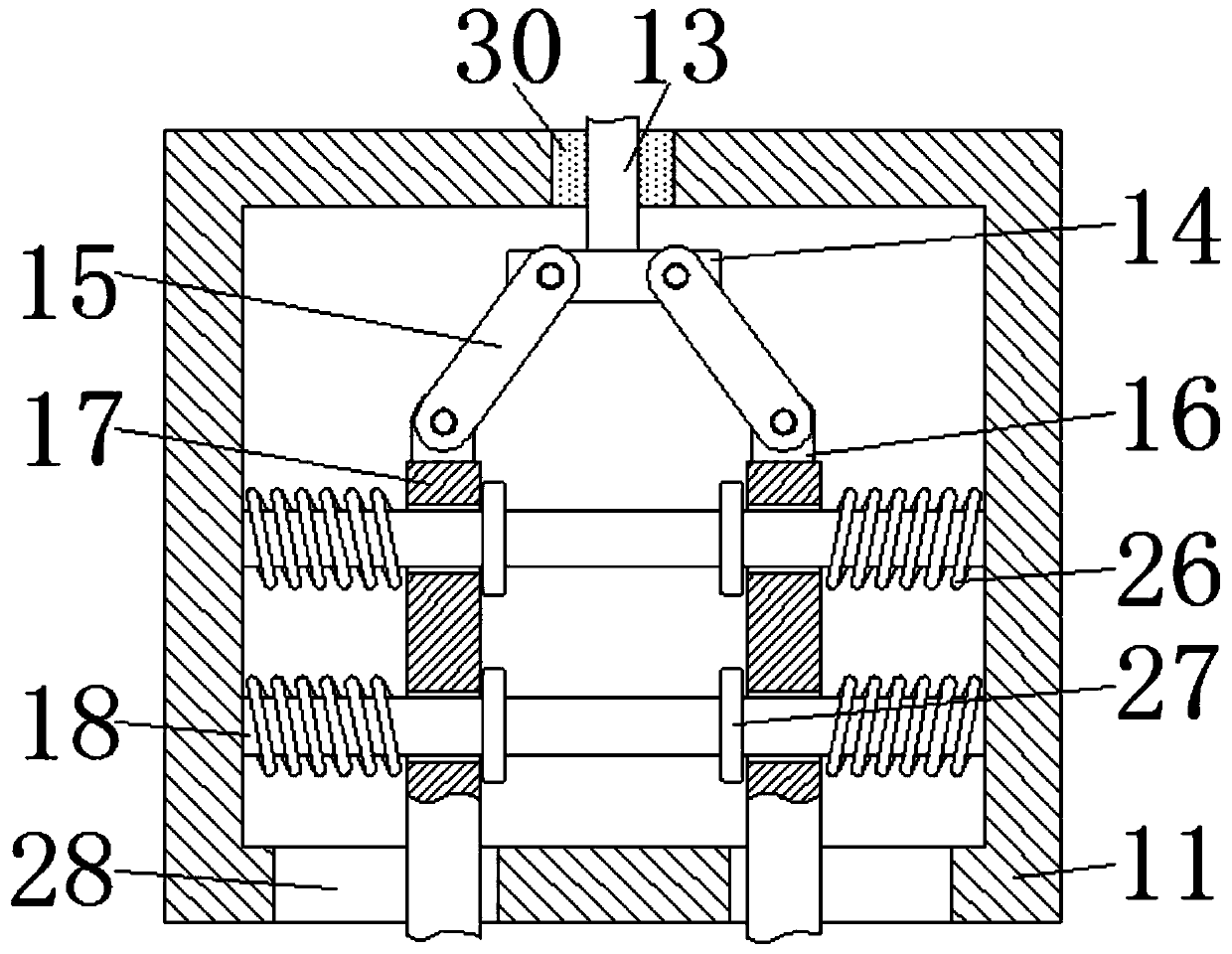

[0037] see Figure 1-7 , a rust-resistant and durable gate valve, including a pipeline 1, the top of the pipeline 1 is fixedly connected with a first fixed pipe 2, and the top of the first fixed pipe 2 is provided with a second fixed pipe 3, and the top of the pipeline 1 A baffle 4 is arranged inside, and the top of the baffle 4 runs through the pipeline 1, the first fixed pipe 2 and the second fixed pipe 3 from bottom to top and extends to the top of the second fixed pipe 3. The top of the baffle 4 The top is provided with a bearing 5, and both sides of the bearing 5 are provided with a clamping mechanism 6, the clamping mechanism 6 includes a third fixed block 601, and the side of the third fixed block 601 close to the bearing 5 is fixedly connected to the surface of the bearing 5 The back of the third fixed block 601 is movably connected with the second transmission rod 602 through the third rotating shaft, and the bottom of the second transmission rod 602 close to the side...

Embodiment 2

[0041] Such as Figure 8 , 9 , 10, on the first fixed rod 9, the position corresponding to the screw rod 7 is fixedly installed with a dust removal device 40, the dust removal device 40 includes a spiral tube 41 and a fan 42, and the fan 42 is fixed on the first fixed rod 9, and the spiral tube 41 and the fan 42 go out The tuyere is connected, and one end of the spiral tube 41 is fixedly arranged on the first fixed rod 9, and the spiral tube 41 is spirally arranged along the screw thread of the screw rod 7. On the spiral tube 41, a number of air injection holes 43 are uniformly provided on the side corresponding to the screw rod 7, and each air injection hole 43 The ring-shaped brushes 44 are all fixedly arranged, and the ring-shaped brushes 44 are arranged along the sides of the air injection holes 43 .

[0042] The spiral tube 41 is located below the first fixed rod 9, and a spiral polishing sheet 45 is fixedly arranged above the first fixed rod 9. One end of the spiral pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com