Hypergravity two-dimensional rock mass model experiment device and method

A model experiment and supergravity technology, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problem of difficulty in providing a large amount of data for model experiments, demanding acoustic emission technology, and limited accuracy of crack identification, etc. problems, to achieve the effects of cost reduction, lower sealing requirements, and increased monitoring density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

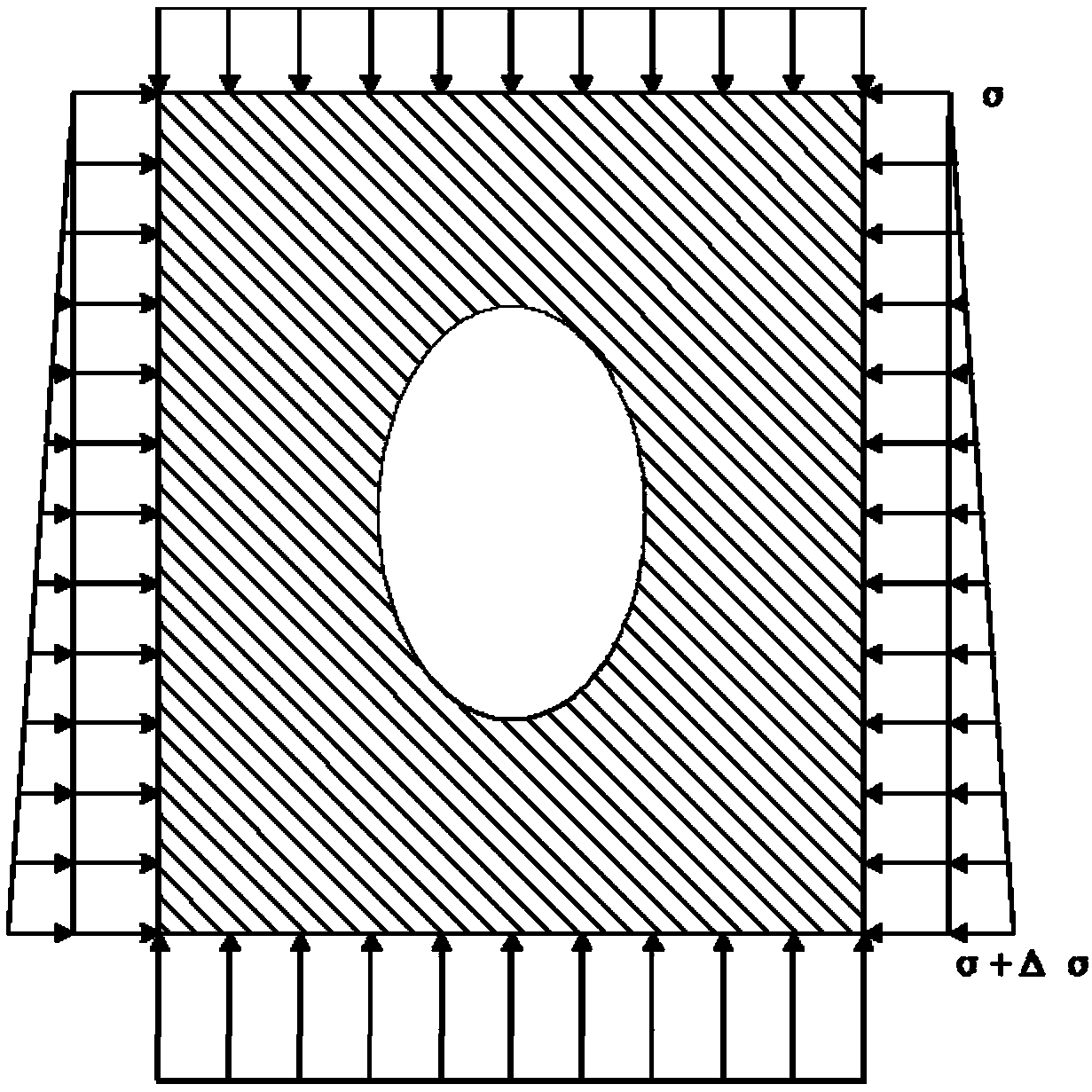

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

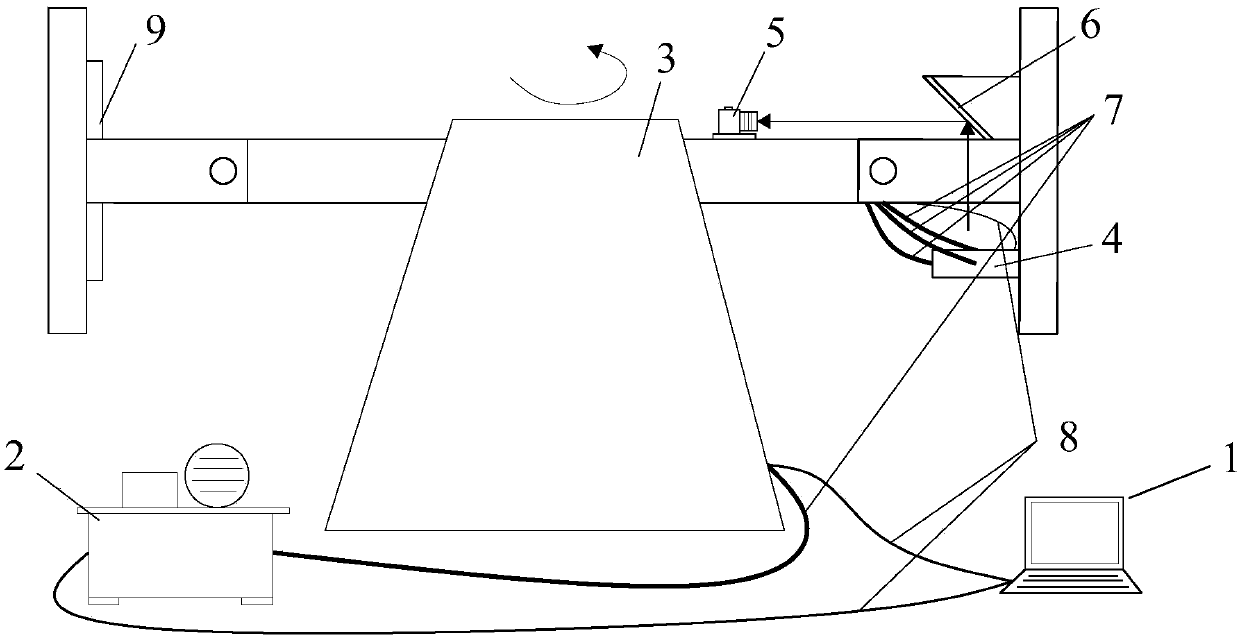

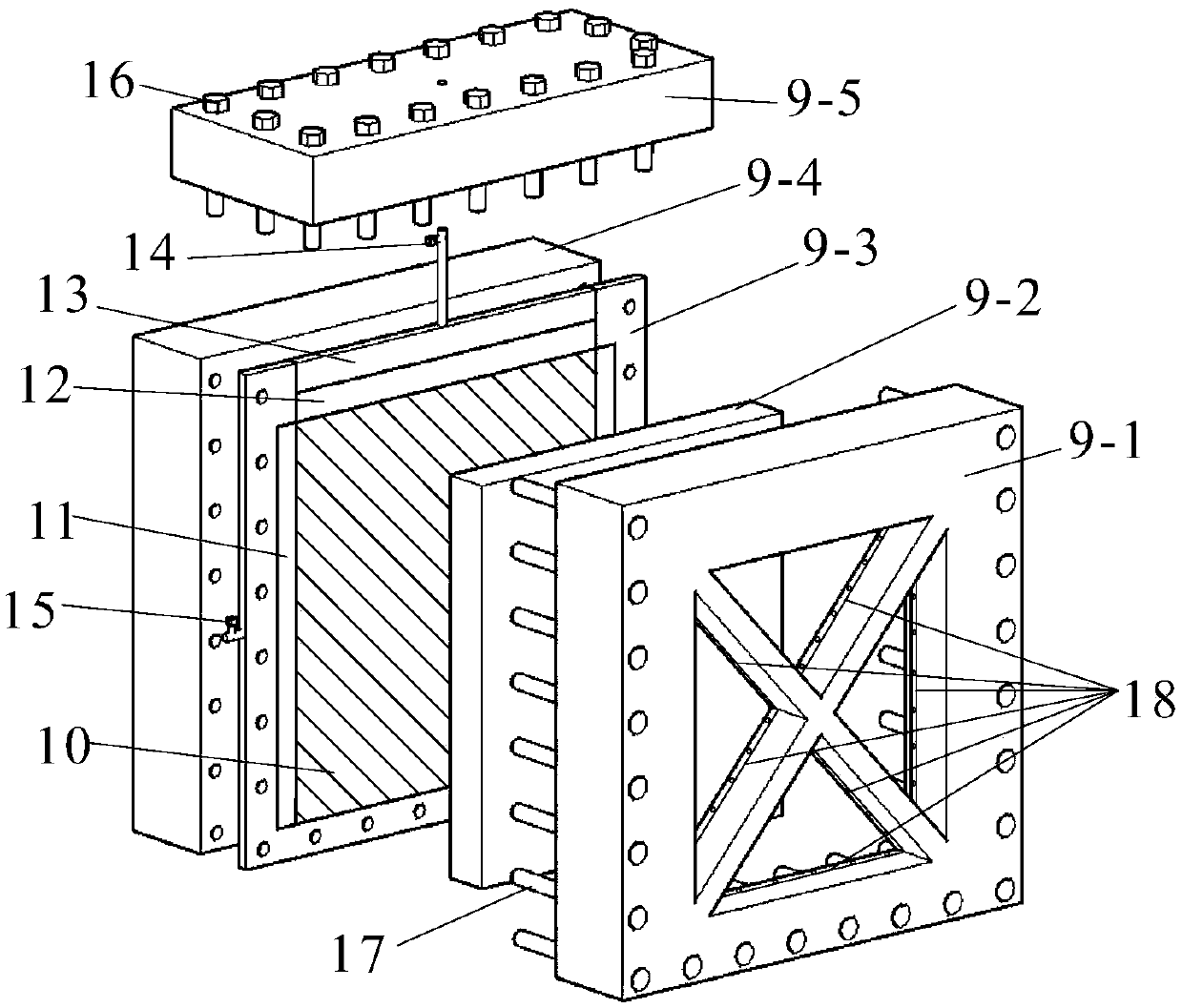

[0044] Such as Figure 2-4 As shown, a high-gravity two-dimensional rock mass model experimental device proposed in this embodiment includes a control center 1, a ground oil source 2, a centrifuge 3, a rock loading box 4, an image observation device, oil pipes 7, cables 8, Counterweight 9; wherein, the rock loading box 4 includes a reaction box frame, a flaky rock sample 10, a confining pressure oil bag 11, a rigid axial pressure head 12, an axial pressure oil bag 13, an axial pressure sensor 14, Pressure sensor 15, first bolt 16, second bolt 17, lighting strip 18.

[0045]The counterforce box frame is an assembled type, and its structure includes a hollow front panel 9-1, a transparent panel 9-2, a middle partition panel 9-3, a back panel 9-4, and a top cover 9-5. The transparent plate 9-2 is embedded in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com