Novel computer mainframe box

A main box and computer technology, applied in the computer field, can solve the problems of affecting heat dissipation effect, troublesome dust cleaning, poor heat dissipation effect, etc., and achieve good heat dissipation effect, avoid inconvenient cleaning, and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

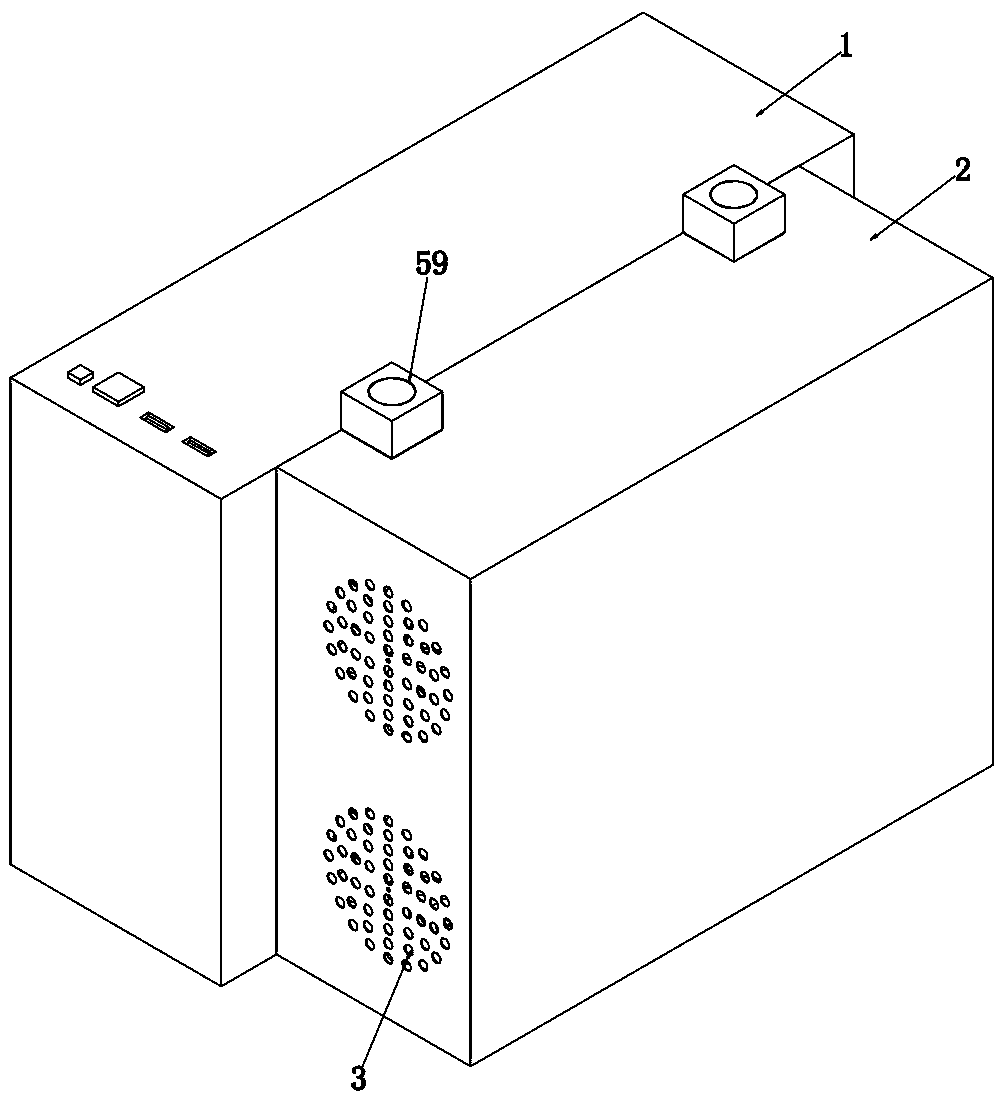

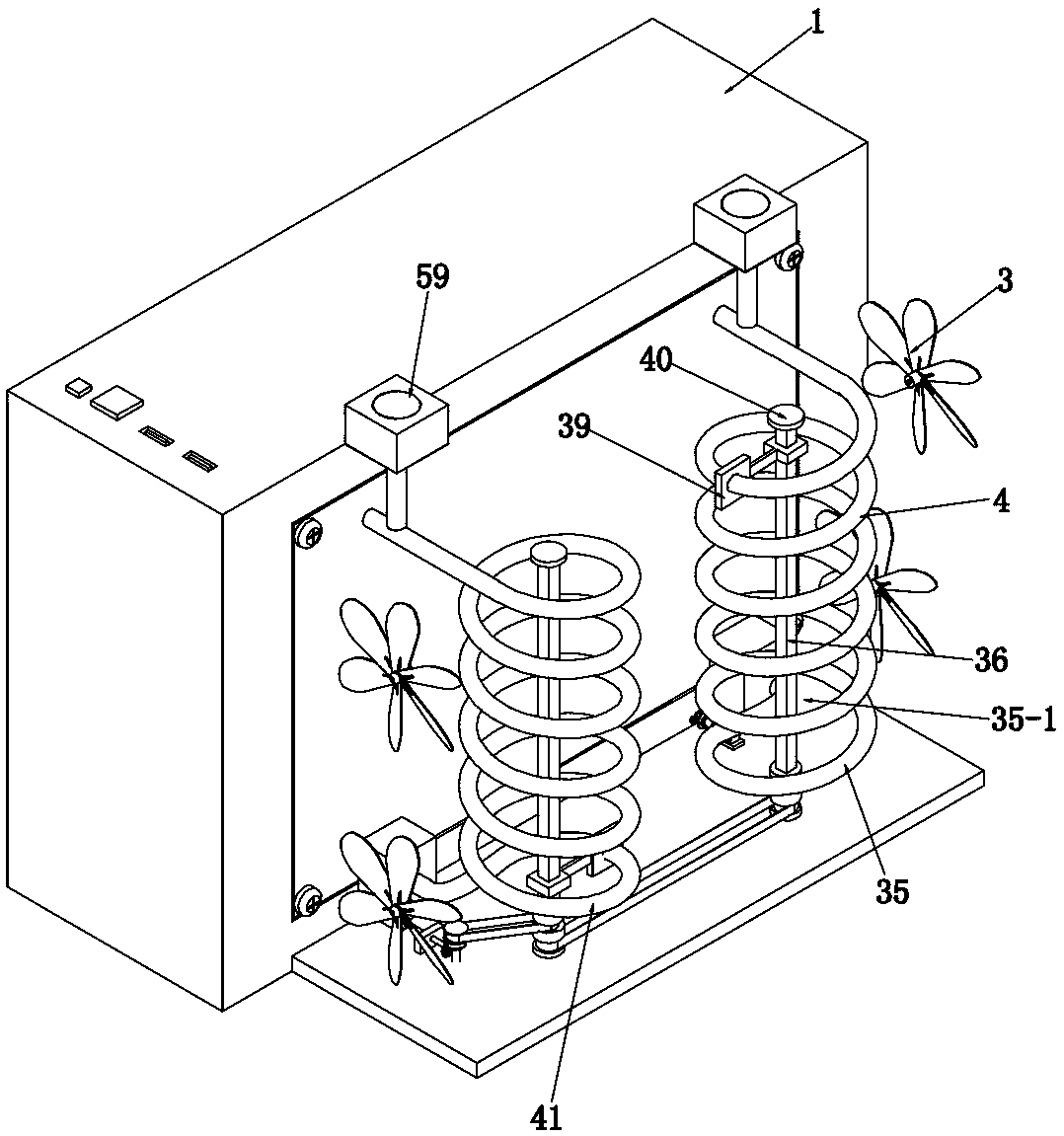

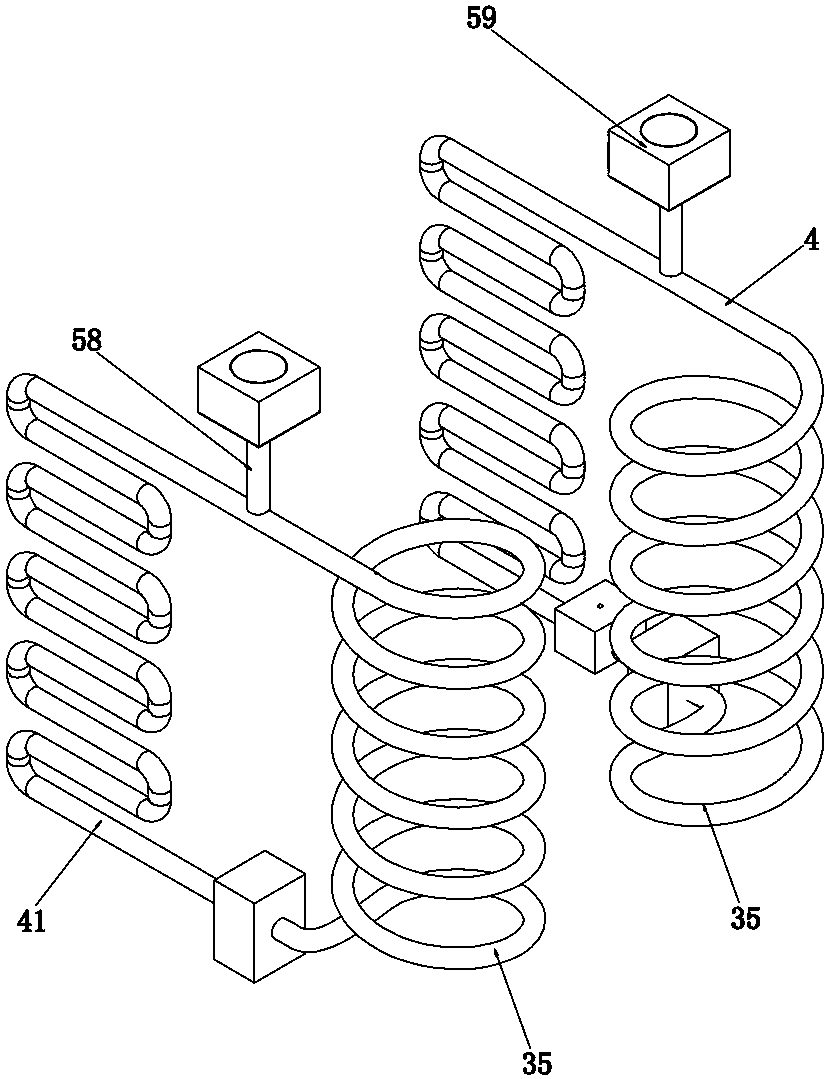

[0042] Embodiment 1, the present invention is a kind of novel computer main frame, please refer to figure 1 and figure 2 , including the main chassis 1, the main chassis 1 is externally closed, which is different from the heat dissipation holes provided by the traditional main chassis. The main chassis will not have external dust entering, which then affects the heat dissipation of the parts inside the main chassis 1, so One side of the main chassis 1 is fixedly installed with a heat dissipation box 2 which is hollow inside, and the heat dissipation box 2 is used for cooling the main chassis 1. Please refer to figure 1 and figure 2 , the front and rear ends of the cooling box 2 are equipped with a cooling fan 3, the cooling fan 3 transfers the heat inside the cooling box 2 to the outside, and the cooling fan 3 is driven by the switch control of the main box 1, that is, the main box 1 is turned on When the cooling fan 3 is turned on synchronously to dissipate heat, when the...

Embodiment 2

[0047] Embodiment 2, on the basis of Embodiment 1, in order to realize the adjustment of the flow rate, when the temperature of the device rises, the flow rate of the condensing agent inside the cooling pipe 4 increases to accelerate heat dissipation; please refer to Image 6 The flow rate adjusting device 10 also includes a first bevel gear 21 coaxially fixedly connected to the lower end of the impeller 11, the first bevel gear 21 meshes with a second bevel gear 22, and the second bevel gear 22 is coaxially connected with a second bevel gear a pulley 23, see Figure 10 , the first pulley 23 is connected with a speed regulating device 25 through a belt 24, and the speed regulating device 25 includes a continuously variable transmission wheel 26 arranged along the left and right direction and connected with the first pulley 23 through a belt 24. Step speed change wheel 26 comprises relative first conical wheel 27 and second conical wheel 28, and described second conical wheel 2...

Embodiment 3

[0049] Embodiment 3, on the basis of Embodiment 1, because the heat dissipation of the traditional main chassis is mostly equipped with a fan, the main chassis is ventilated, the heat dissipation effect is not good, and the use of draft heat dissipation makes the airflow not flow well, and the heat dissipation effect no, see figure 2 The cooling fan 3 installed on the front end of the cooling box 2 draws air toward the inside of the cooling box 2, and the cooling fan 3 installed on the rear end of the cooling box 2 blows air toward the outside of the cooling box 2, through two groups of cooling fans 3 at the front and rear ends. Cooperating with the heat dissipation, the fluidity of the airflow inside the heat dissipation box 2 is accelerated, so that the heat dissipation effect is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com