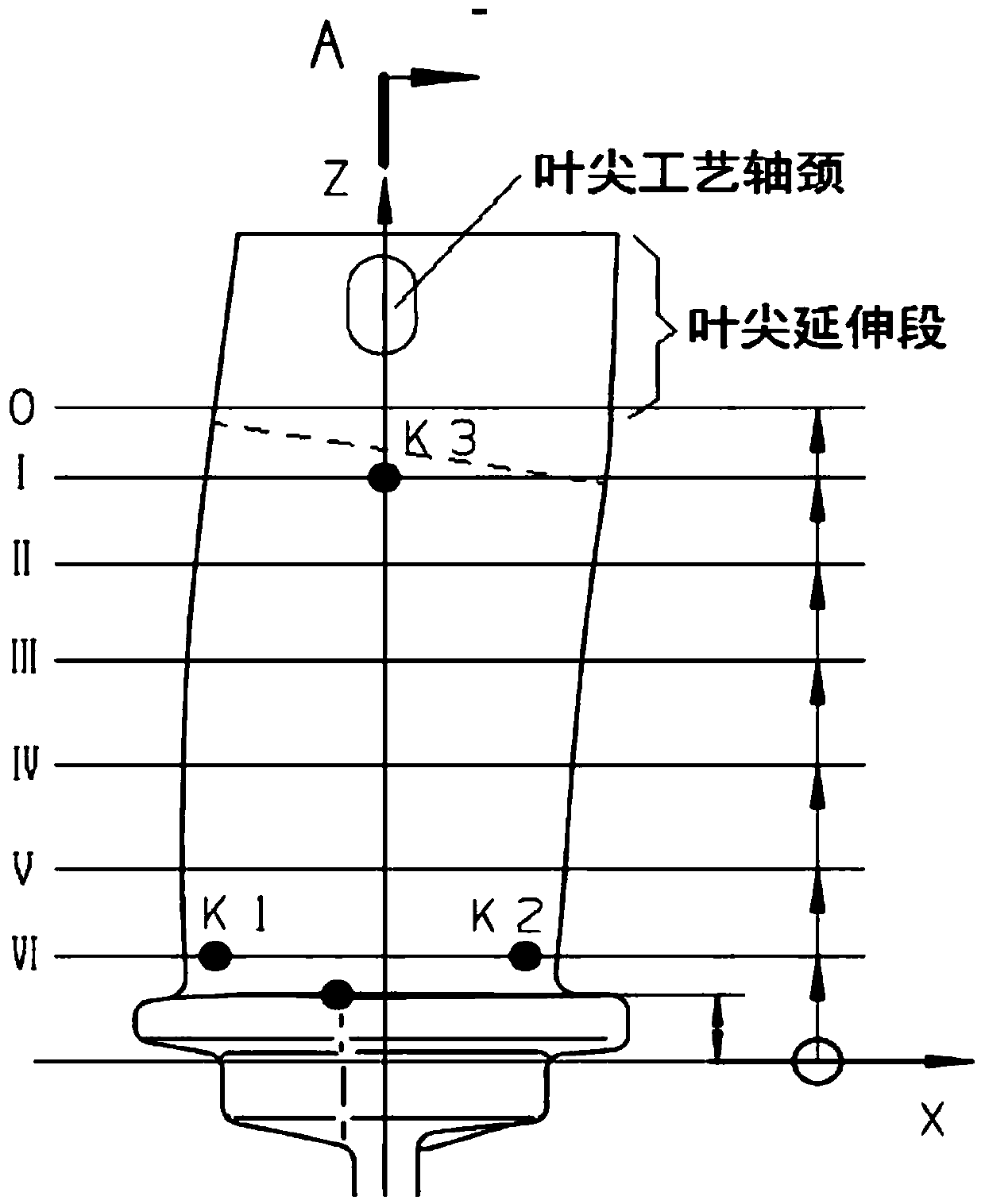

A modeling method for a blade tip process extension section of a rotor blade forge piece

A technology of rotor blade and modeling method, which is applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve the problems of large springback deformation, affecting the positioning accuracy of blade machining, and large fitting error of positioning point K3 of the tip section. , to achieve the effect of accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Embodiment: the purpose of the invention is achieved by the following technical solutions:

[0026] 1. Analyze the airfoil shape line data: according to the airfoil coordinate representation format specified in HB5647-98 "Blade Airfoil Labeling, Tolerance and Airfoil Surface Roughness", the blade body shape line coordinate points in the blade design drawing Automatic analysis, the analysis process is integrated in the UG plug-in, the technology used for analysis is the mainstream analysis tool: regular expression, java language provides a regex development kit that can perfectly support regular expressions, and can accurately and conveniently analyze leaf points coordinate.

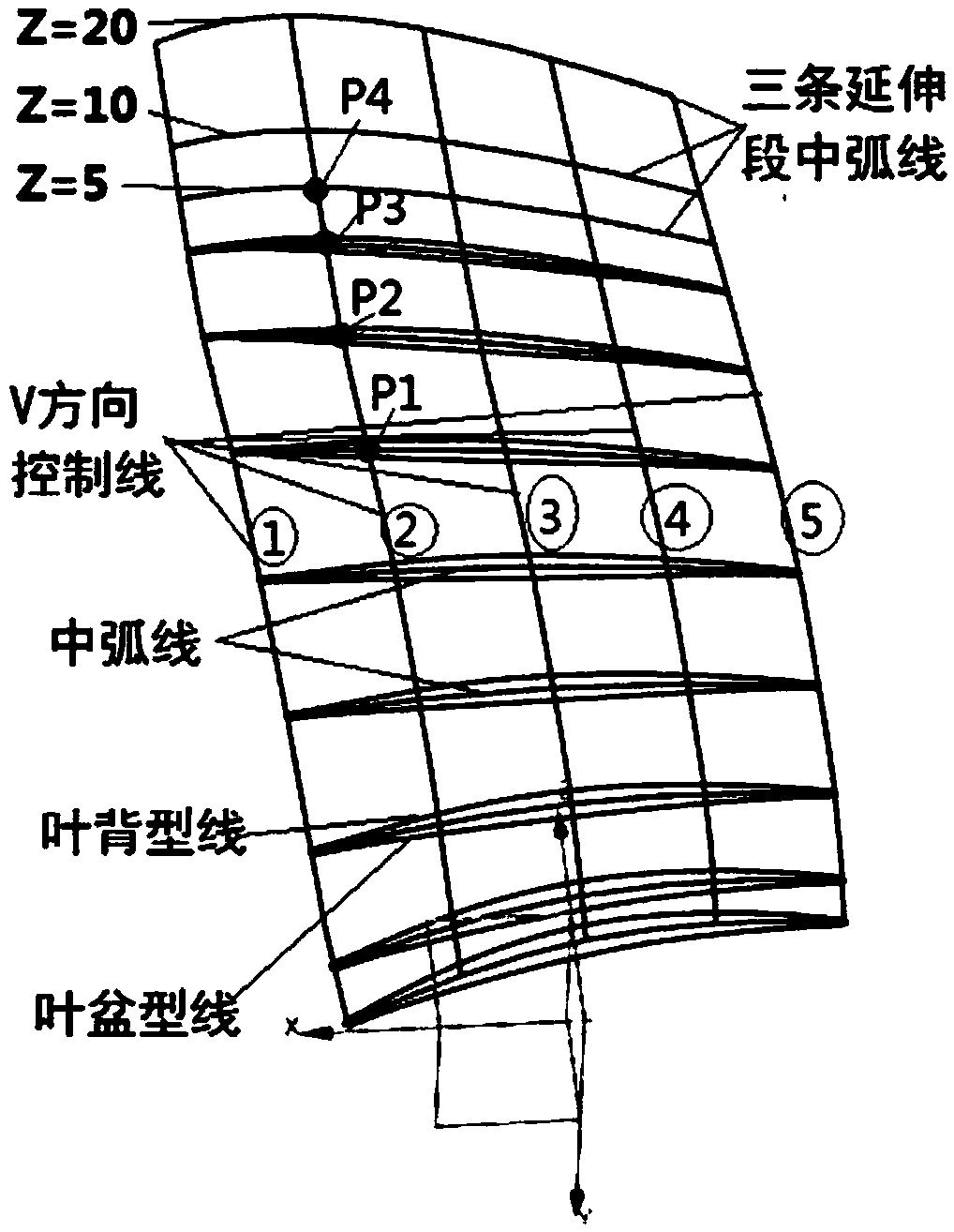

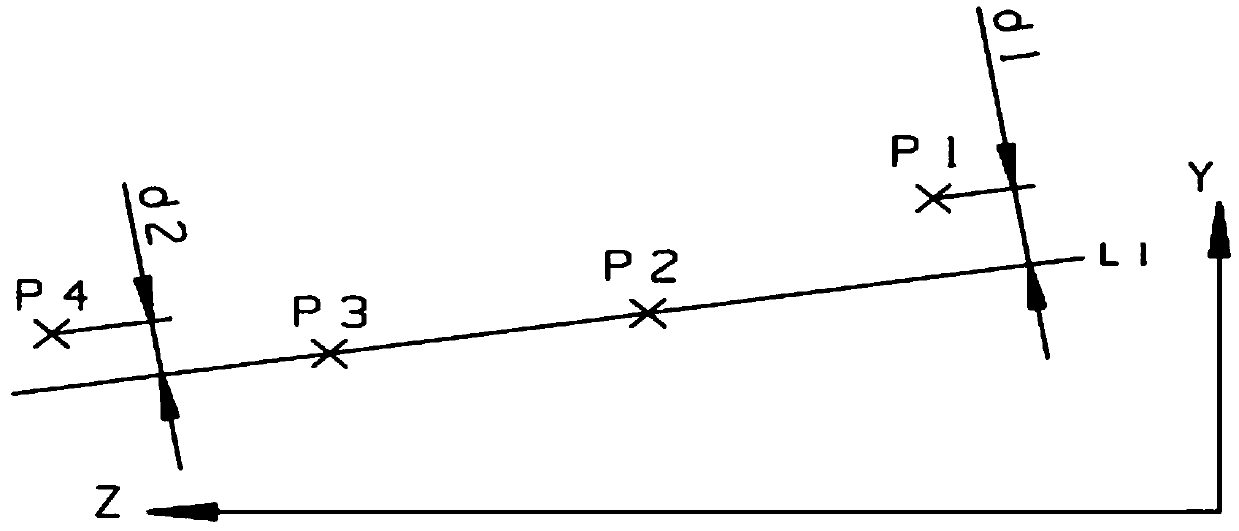

[0027] 2. Calculating the center arc: Calculate the center arc of each blade body section according to the point coordinates obtained by analysis. The center arc is used to observe the trend and does not require high precision. The leaf pot and the leaf back shape line of the body are divided into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com