Molded case circuit breaker

A technology of molded case circuit breaker and casing, which is applied to circuit breaker parts, circuit breaker contacts, protection switch operation/release mechanism, etc. The effect of increasing the pressure, increasing the electric repulsion, and avoiding the damage of the moving contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

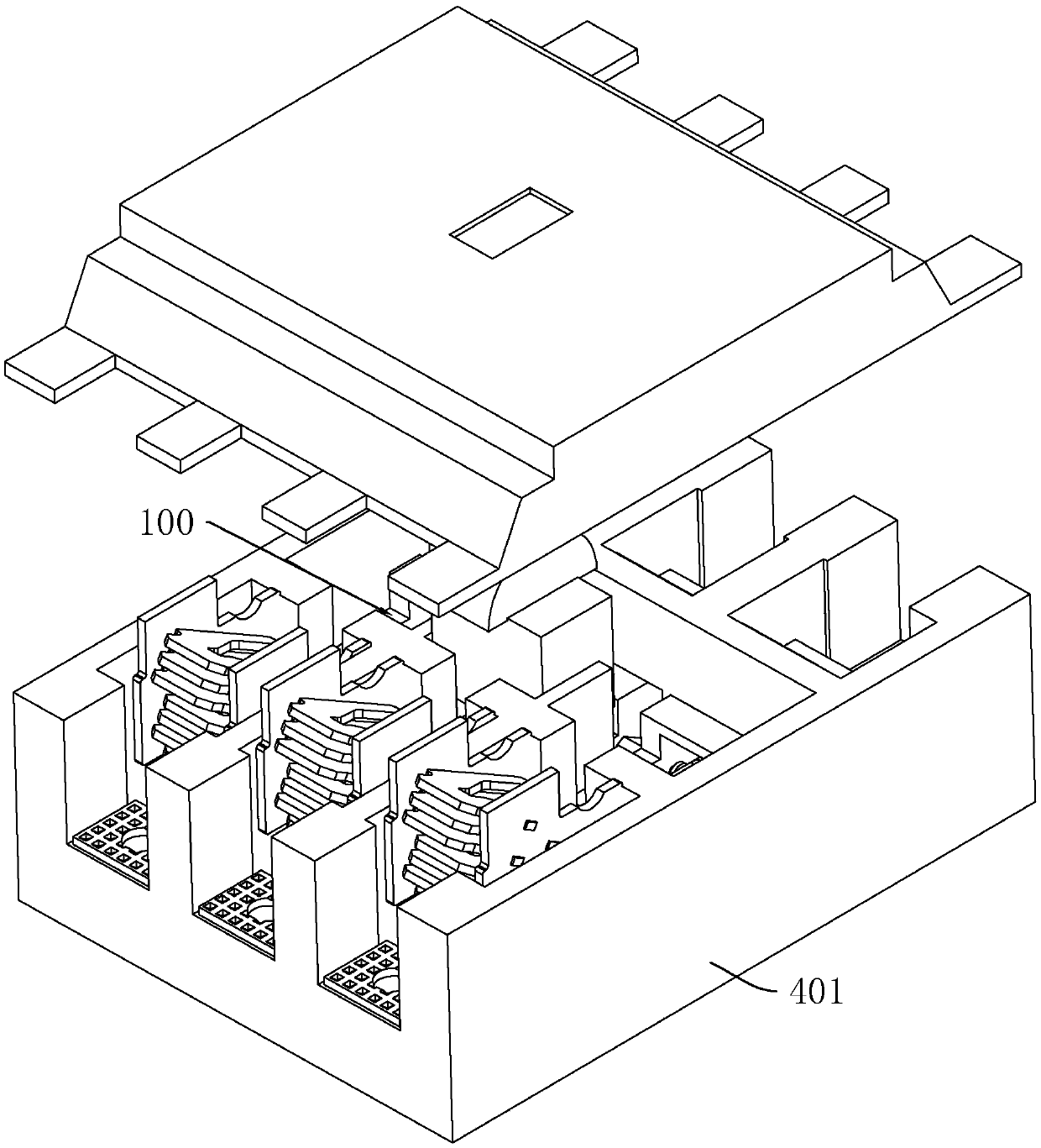

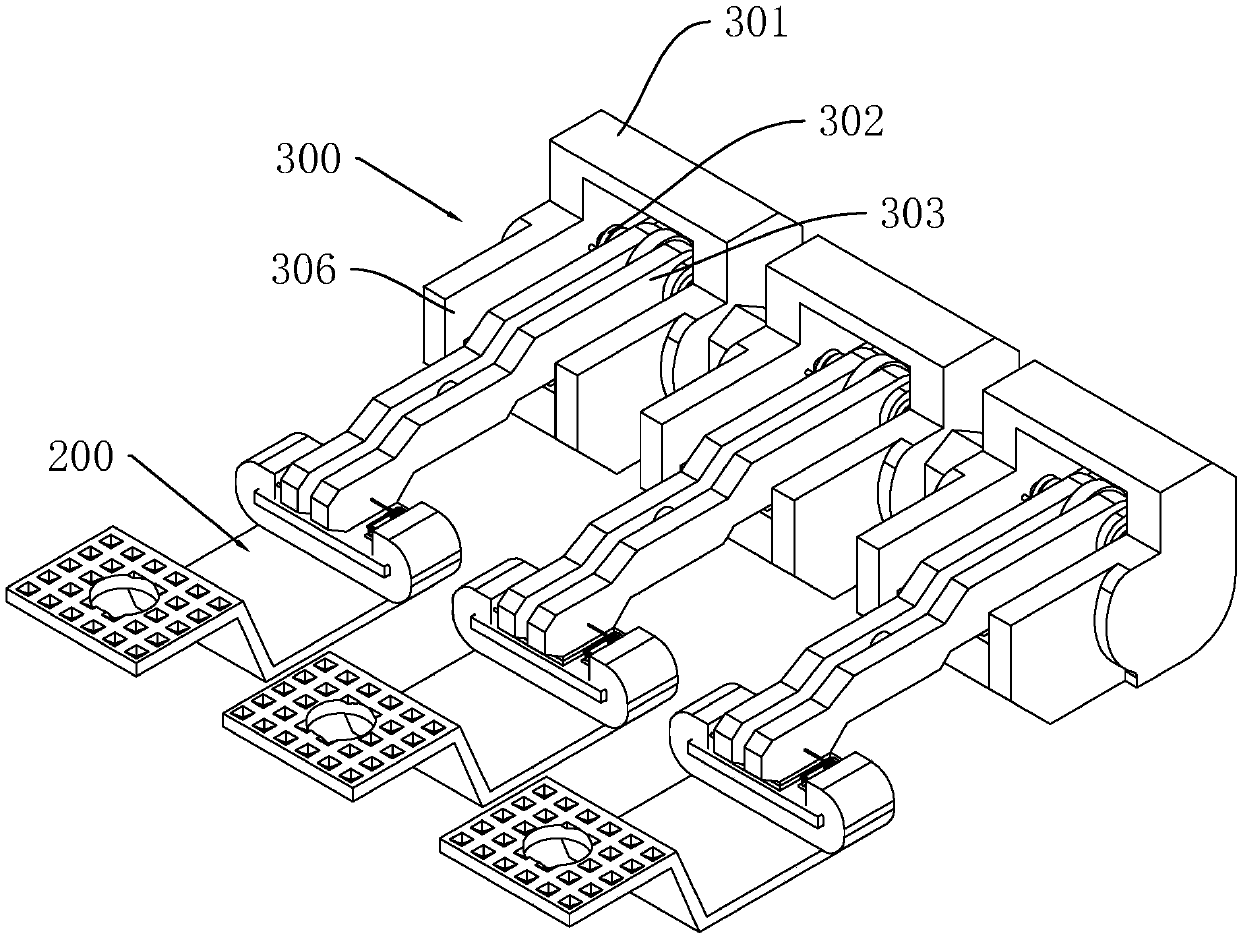

[0039] A molded case circuit breaker, such as figure 1 As shown, it includes a housing 401, a breaking mechanism 100 installed in the housing 401, and a thermal-magnetic release. Under the action of the operating mechanism in the thermal-magnetic release, the moving contact structure 300 and the static contact structure 200 are in contact, thereby realizing The conduction of the circuit breaker.

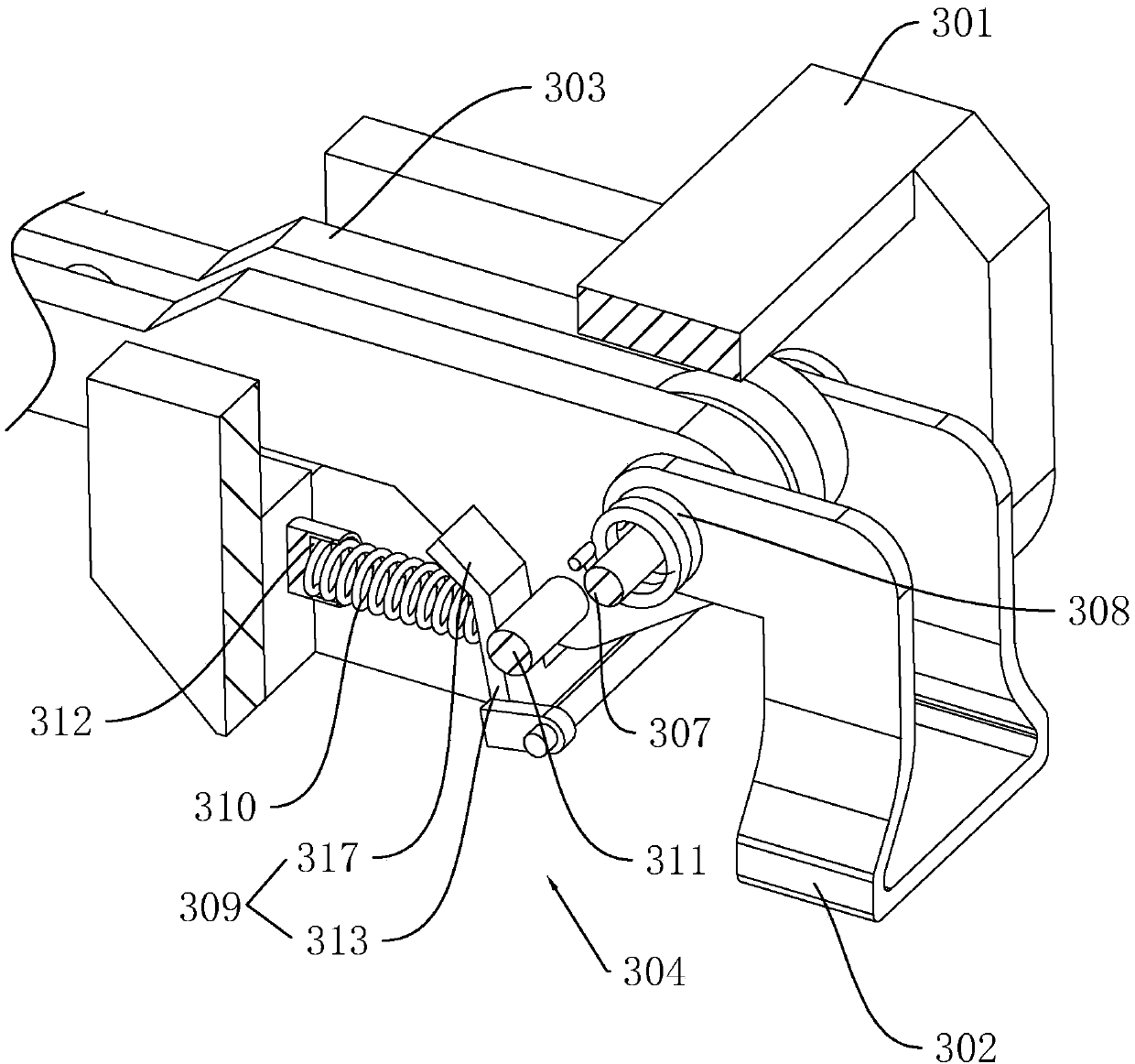

[0040] The moving contact structure 300 includes a rotating shaft housing 301 , a conductive clip 302 and a moving contact 303 . The rotating shaft housing 301 is rotatably connected to the conductive splint 302 , and the movable contact 303 is hinged to the rotating shaft housing 301 . The rotating shaft housing 301 is provided with a mounting groove 306 , and the side wall of the mounting groove 306 is rotatably connected with a first shaft 307 arranged horizontal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com