Rotor sealing structure of locomotive permanent magnet synchronous traction motor

A permanent magnet synchronous, traction motor technology, applied in the magnetic circuit shape/style/structure, electromechanical device, magnetic circuit, etc., can solve the problems of poor cooling effect, complex cooling system structure, etc., to eliminate potential safety hazards and reduce technical risks , Guarantee the effect of safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

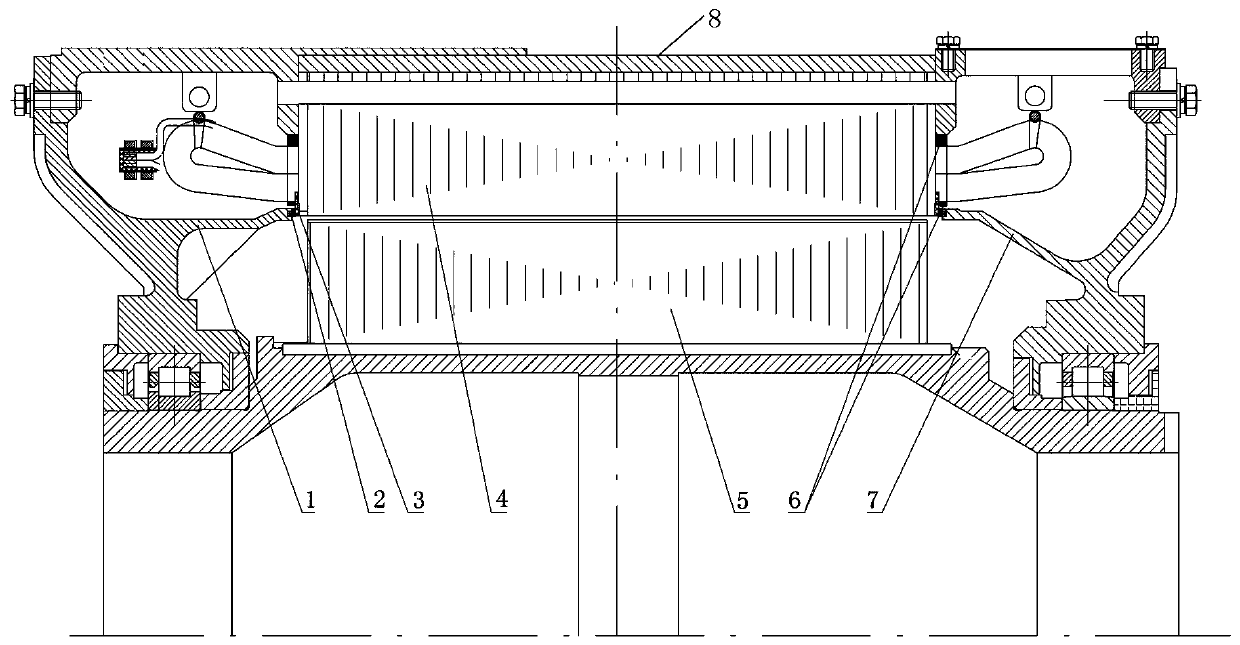

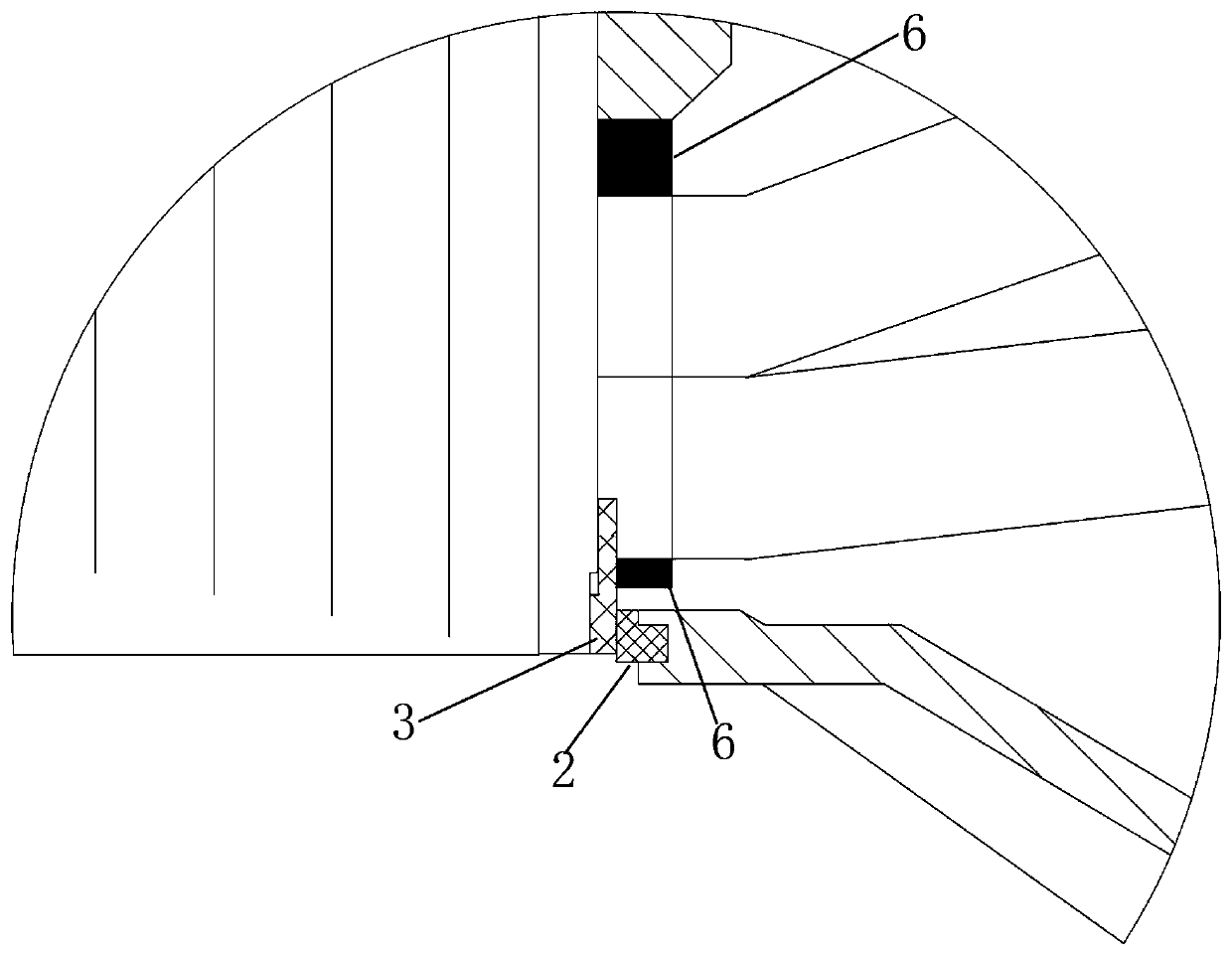

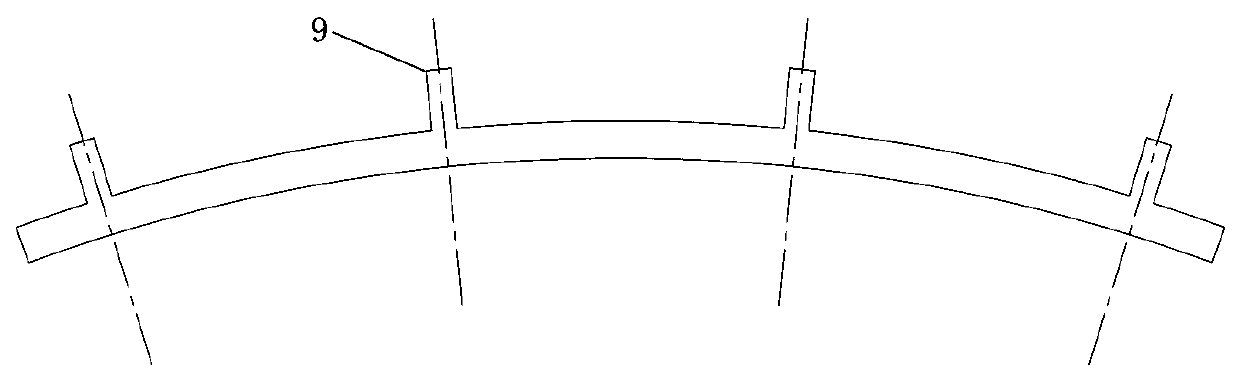

[0029] A rotor sealing structure for a permanent magnet synchronous traction motor of a locomotive, comprising a frame, a rotor core, a stator core, a non-drive end cover, and a drive end cover; the inner sides of the non-drive end cover and the drive end cover both extend toward the inside of the motor And respectively press and butt with the end plates on both sides of the stator core near the inner circle; the end faces of the extension structure of the non-drive end cover and the drive end cover are fixed with sealing strips, and there are fixed installations between the sealing strips and the stator end plates. Ring-shaped sealing plate; there are several tooth-shaped structures evenly distributed on the outside of the annular sealing plate, the tooth-shaped structures correspond to the stator slots, and the tooth-shaped structures are fastened to the stator end plate by sealant, and then cooperate with the sealing strip Seal the rotor core.

[0030] There is an annular g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com