Self-switching type bi-directional injection molding machine head

An injection molding machine, self-switching technology, applied in the field of self-switching two-way injection molding machine head, can solve the problems of easy confusion in the types of injection molding materials, the inability of the factory to develop color numbers, lack of novelty, etc., to reduce the types of purchases and keep clarity degree, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

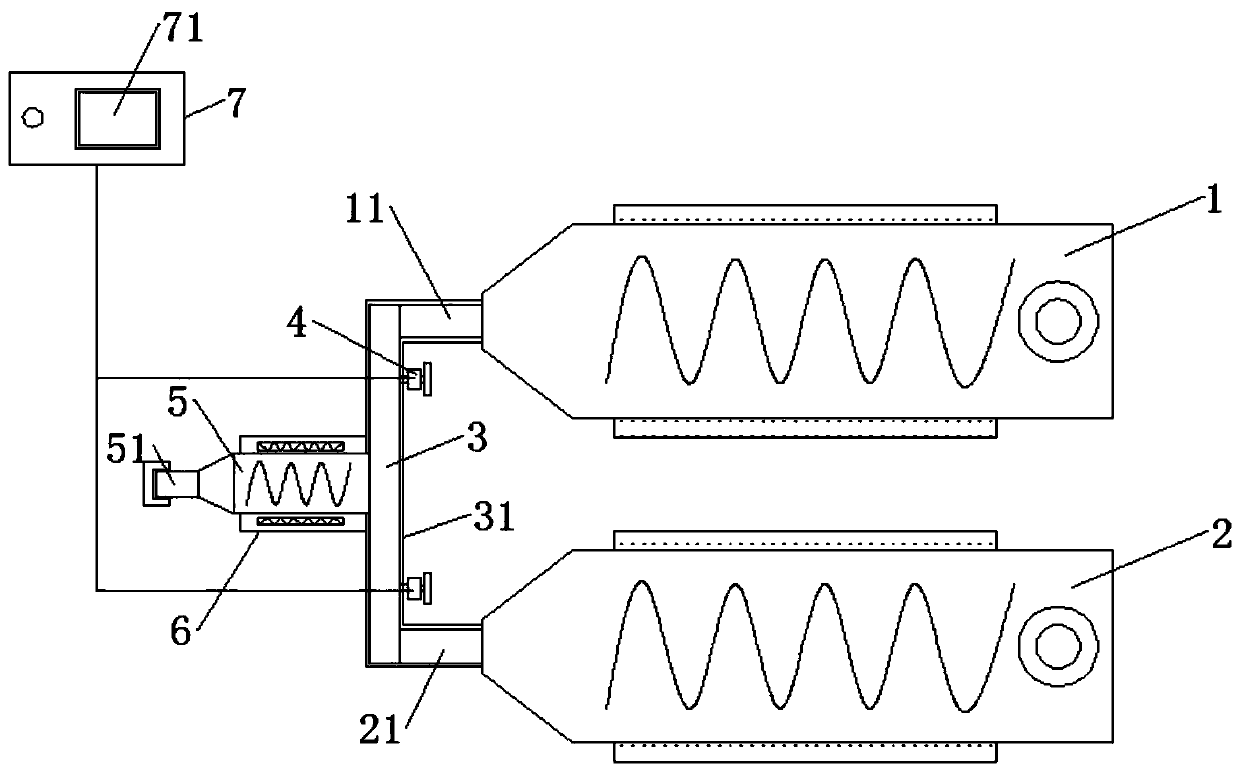

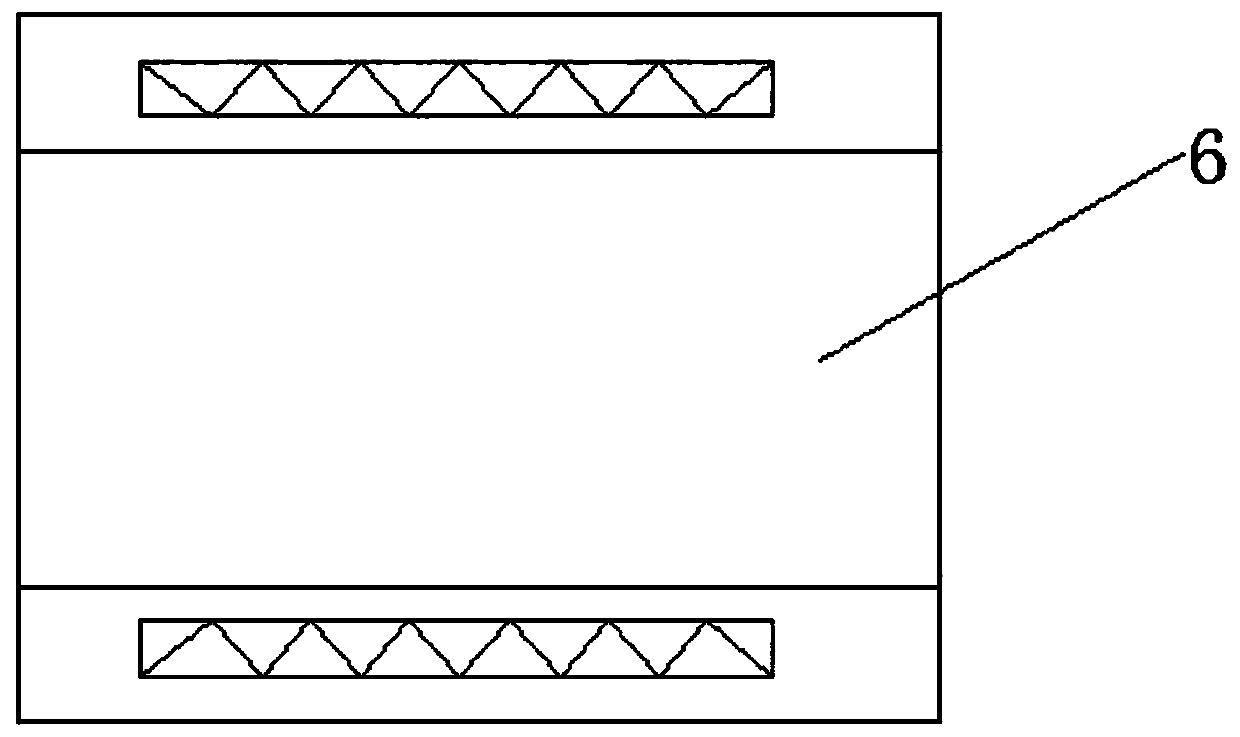

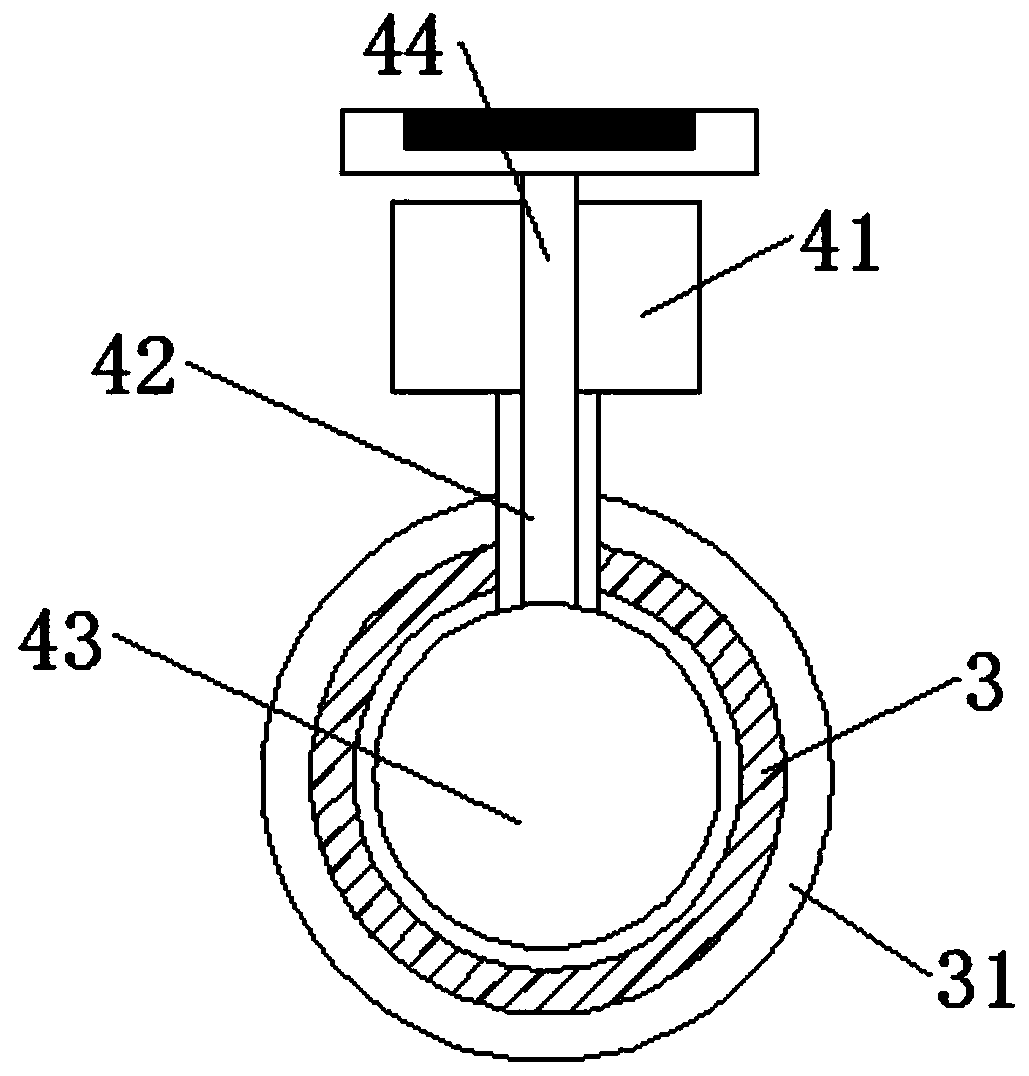

[0039] see Figure 1-5 , a self-switching two-way injection molding machine head, including injection molding machine No. 1 and injection molding machine No. 2, injection molding machine No. 1 and injection molding machine No. 2 are existing injection molding machine structures, and its interior includes a feeding mechanism , screw feeding mechanism and heating mechanism, etc., the ends of injection molding machine No. 1 and injection molding machine No. A delivery pipe 3 is connected between the second pair of injection molding heads 21, and the middle part of the end of the delivery pipe 3 far away from the injection molding machine No. One end of the main injection molding machine head 51 is connected, and a pair of pneumatic butterfly valves 4 are connected to the conveying pipe 3, and the pair of pneumatic butterfly valves 4 are respectively located on both sides of the feeding pipe 5.

[0040] The pneumatic butterfly valve 4 includes a pneumatic switch 41, a valve stem 42...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com