Inner drum for washing machine and washing machine

A washing machine and inner drum technology, applied in the field of washing machines, can solve the problems of poor concentricity of the inner drum center of the washing machine, easy corrosion of the tripod, etc., and achieve the effect of increasing the accommodation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

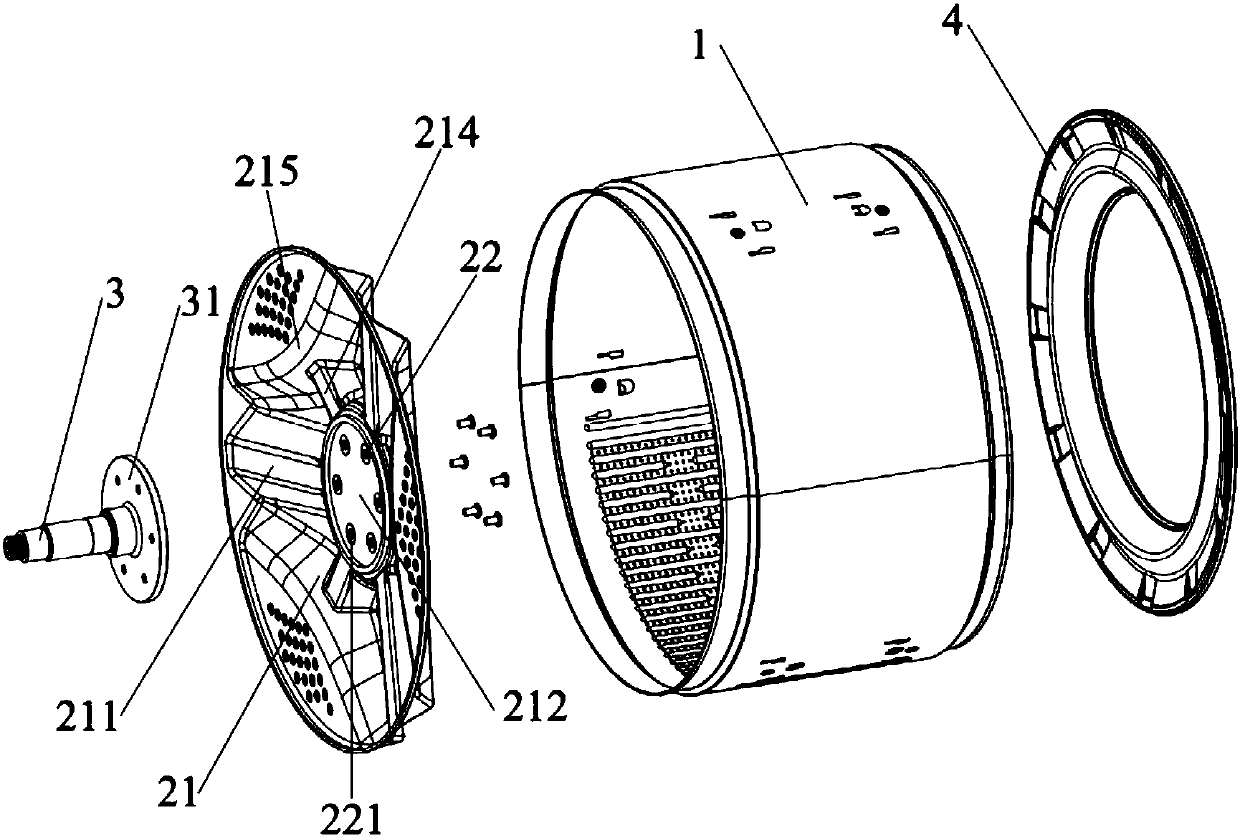

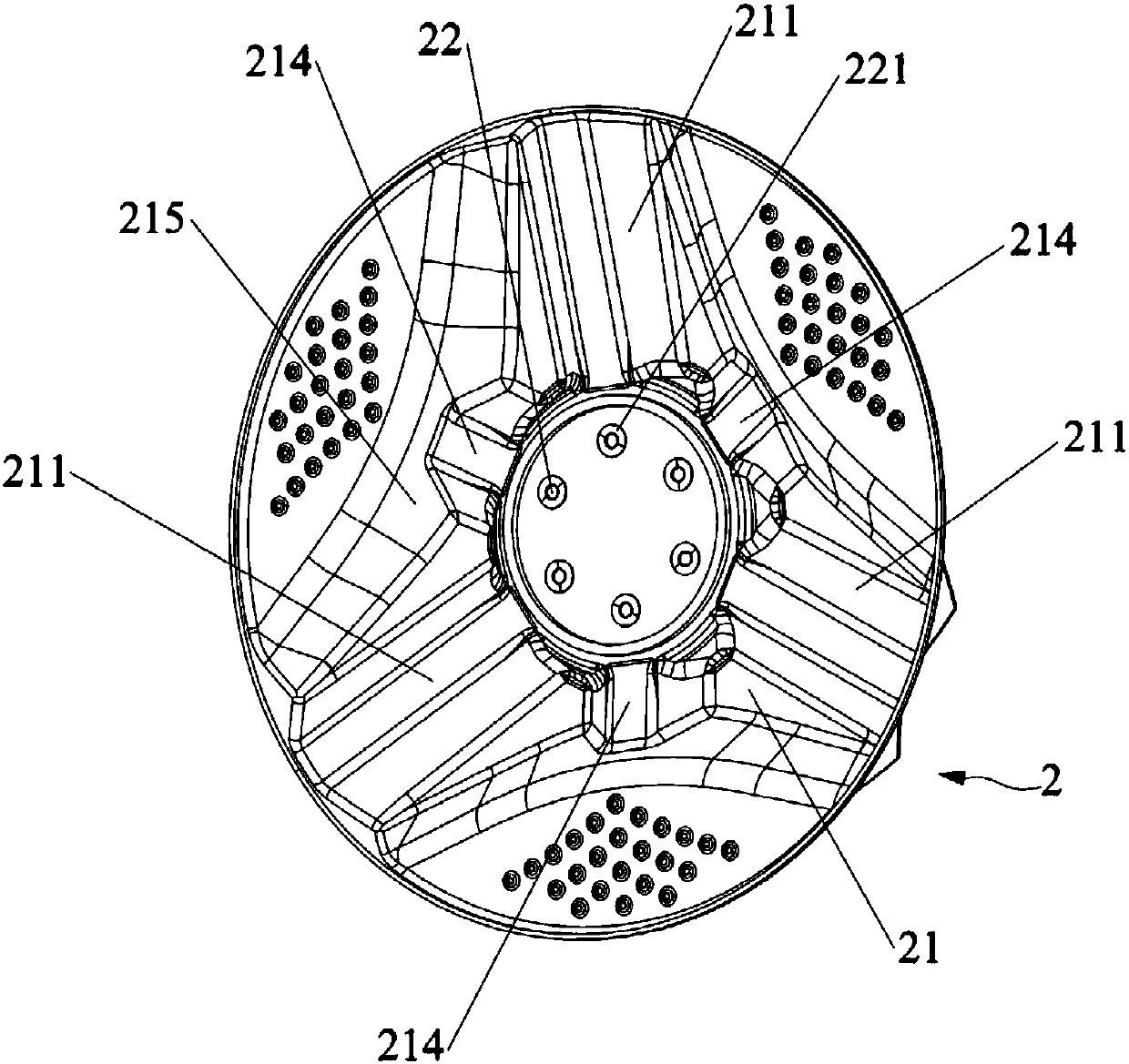

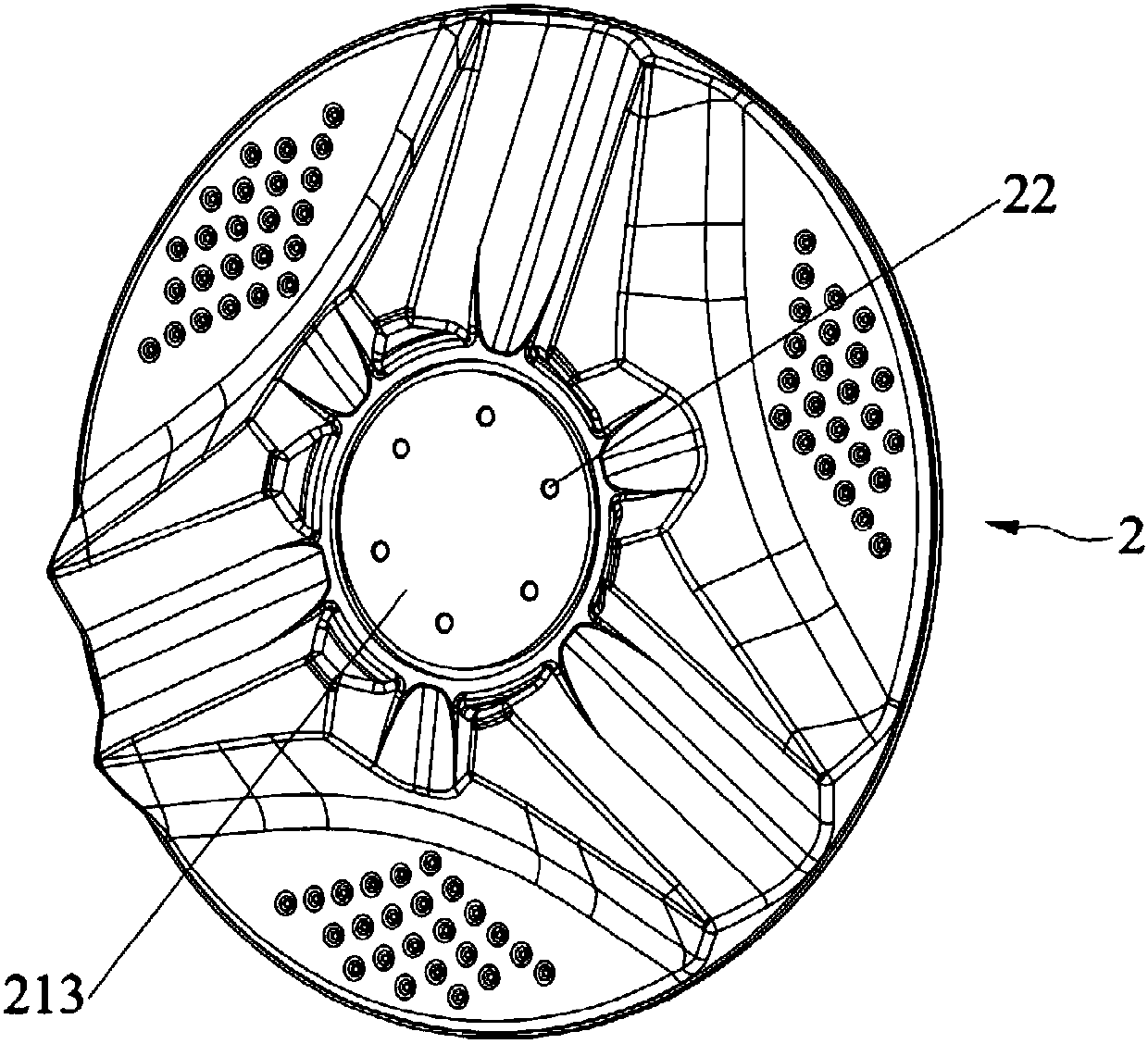

[0026] This embodiment provides a washing machine inner drum 1 suitable for a drum washing machine, such as Figure 1-Figure 3 As shown, the rear flange 2 arranged at one end of the inner drum 1 of the washing machine is recessed toward the inner drum 1 of the washing machine to form a cavity 21, the rotating shaft 3 is fixed at the center of the cavity 21, and the inner wall of the cavity 21 is evenly distributed. There are several reinforcing ribs 211 . Wherein, it should be noted that the outer cylinder of the washing machine is provided with a sealing part for sealing the rotating shaft 3. When the washing water is thrown out by the rear flange 2, the sealing part shields the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com