Cement pavement internal crack monitoring system and crack width and position determining methods

A cement and cement-based technology, applied in measurement devices, electrical devices, instruments, etc., can solve the problems of inability to monitor micro-damage of pavement, lack of autonomy and hysteresis of monitoring methods, and achieve the goal of being suitable for large-scale promotion and application, reducing pavement Monitoring cost, method reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The ceramic micropowder, polyethylene and cement were mixed according to the mass parts of 60, 25 and 15 parts respectively, and a cylinder with a diameter of 10mm and a thickness of 2mm was formed by hot pressing, and the cylinder was the asphalt piezoelectric material. Among them, the hot pressing conditions are as follows: temperature 130°C, pressure 14MPa, time 2min; then the pitch-based piezoelectric material is subjected to polarization treatment, the polarization conditions are: polarization electric field strength 2.5kV / mm, polarization temperature 120°C, The polarization time is 15 minutes; the cement-based piezoelectric material and the copper plate with a diameter of 15 mm and a thickness of 3 mm are bonded together through conductive adhesive, and a silicone waterproof layer is applied on the outside.

[0055] Mix 20 parts of cement, 40 parts of epoxy resin, 20 parts of aggregate and 20 parts of mineral powder to form the sealing solution. Apply encapsulatio...

Embodiment 2

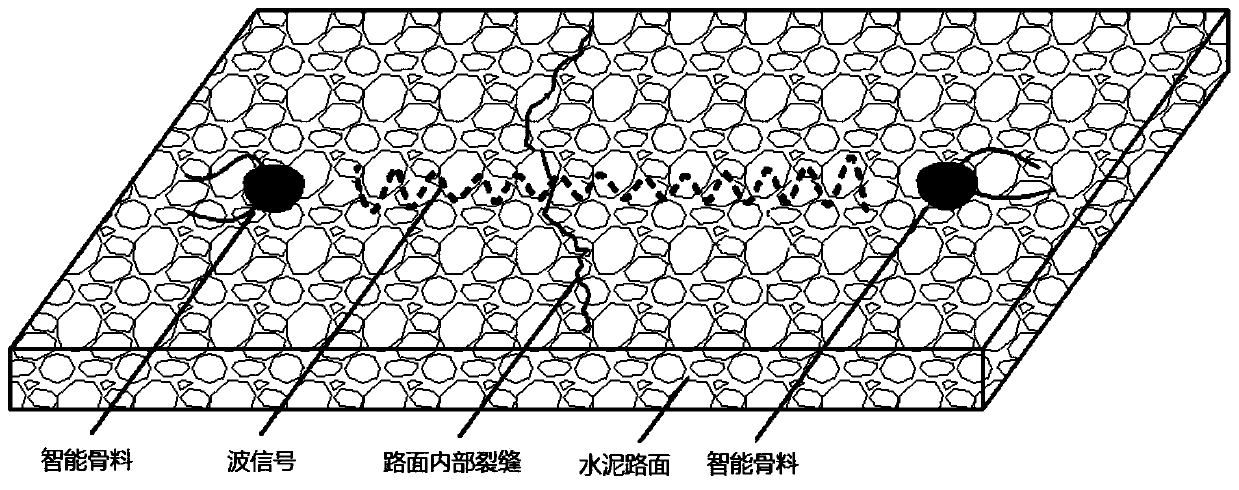

[0057] The piezoelectric intelligent aggregate prepared in Example 1 is evenly buried at the bottom of the cement surface layer at intervals of 1 to 1.5 meters, and the wire of the intelligent aggregate is extended to the outside of the roadway or road shoulder, such as figure 1 shown. Every two adjacent electrical smart aggregates are respectively electrically connected to a signal generator and a charge amplifier, and an oscilloscope is connected to the charge amplifier to form a monitoring system for cracks inside the pavement.

Embodiment 3

[0059] (1) Signal measurement when not open to traffic

[0060] When it is not open to traffic, the signal generator is used to transmit sine wave signals of different amplitudes to the cement-based piezoelectric intelligent aggregate, and the adjacent intelligent aggregate is connected to the charge amplifier, and the signal is transmitted to the oscilloscope to test the amplitude of the output signal. The results are shown in Table 1.

[0061] Table 1: Output signal amplitude when not in traffic

[0062]

[0063] (2) Signal measurement for 1 year after opening to traffic

[0064] One year after it was opened to traffic (annual average daily traffic volume is 4,000 vehicles / day), the signal generator is used to transmit sine wave signals of different amplitudes to the cement-based piezoelectric smart aggregate (consistent with that before it was opened to traffic), adjacent to it The smart aggregate is connected to the charge amplifier, the signal is transmitted to the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Crack width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com