Active infrared thermal wave detection method and system for glass curtain wall cementing structure damage

A technology for glass curtain wall and structural damage, applied in radiation pyrometry, measuring device, material defect testing, etc., can solve the problem of inability to directly detect structural adhesives, and achieve convenient heating control, high energy density, and low power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

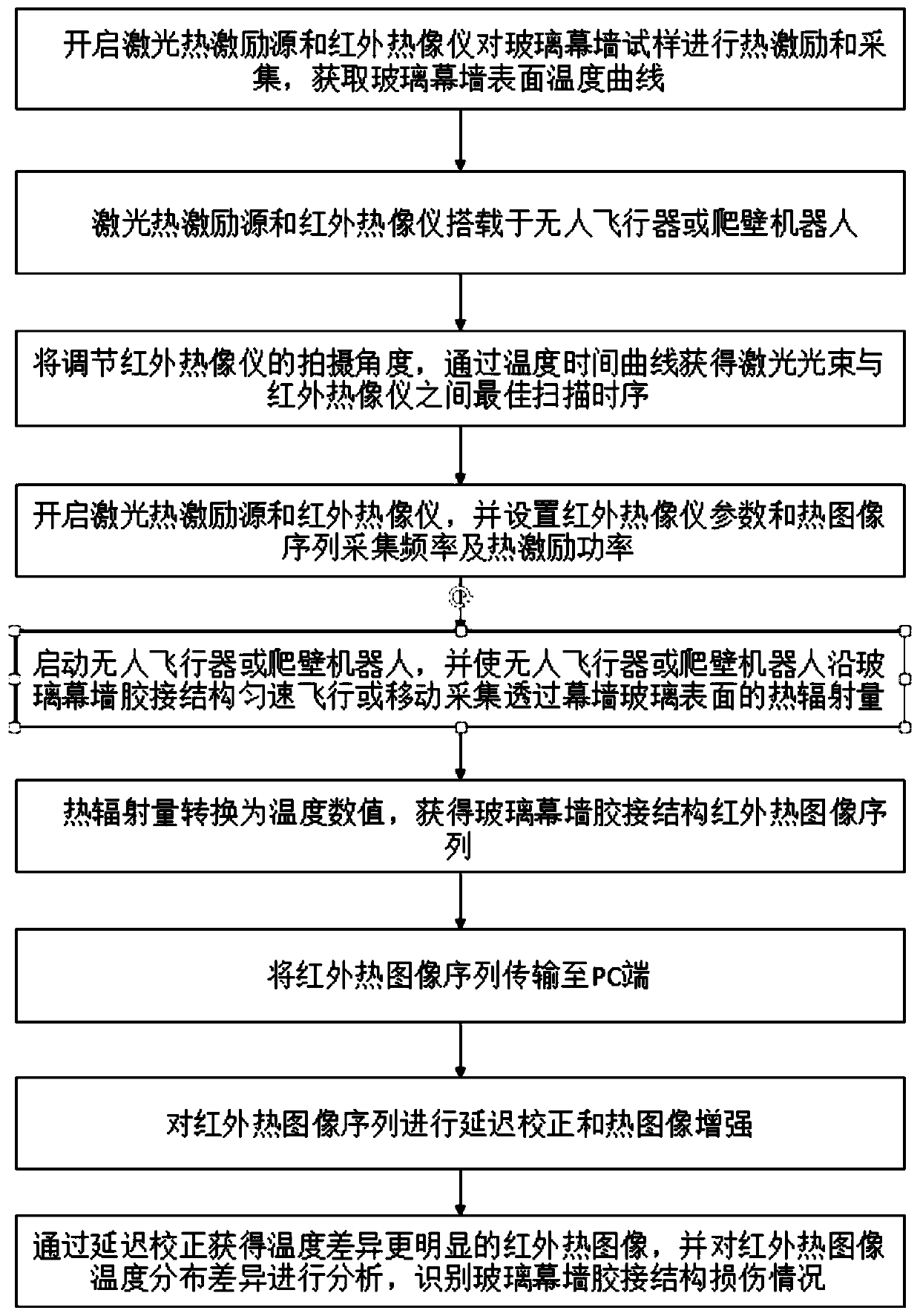

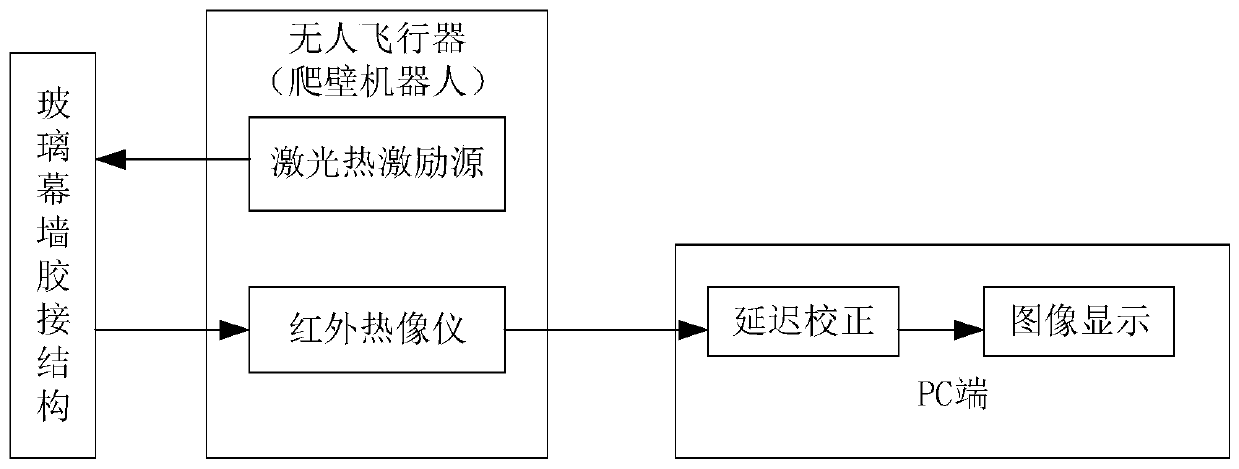

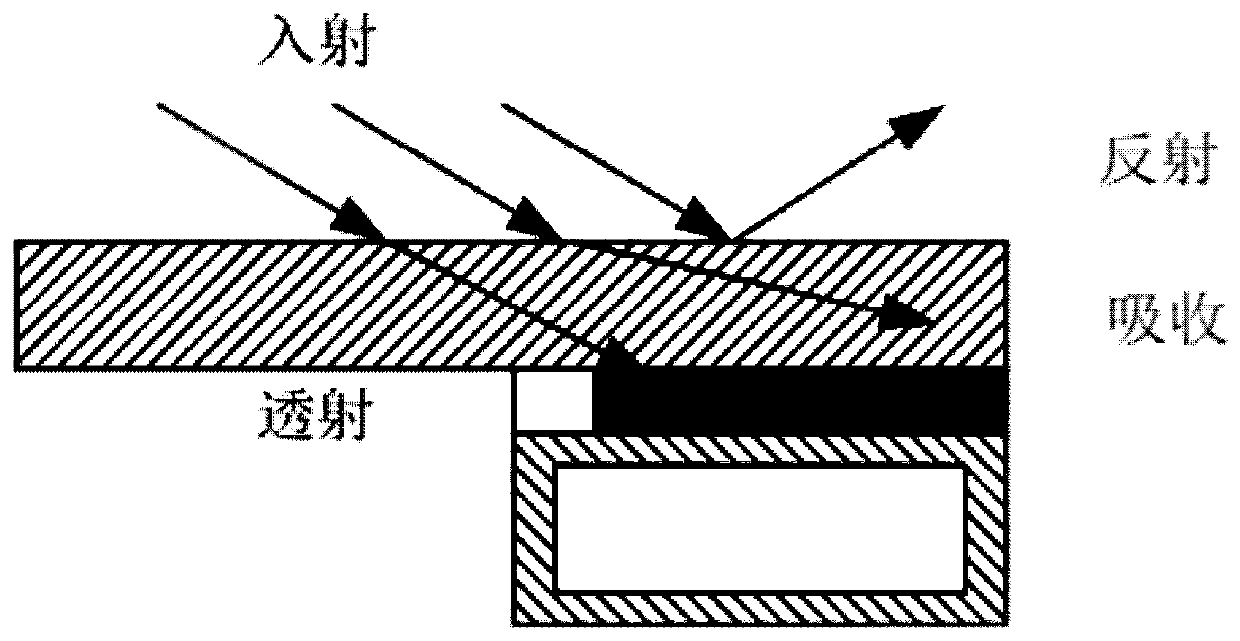

[0033] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and the accompanying drawings: the purpose of the present invention is to provide a kind of active infrared heat wave facing the damage of the glass curtain wall adhesive bonding structure Detection method and system, the detection method and system use an unmanned aerial vehicle or a wall-climbing robot equipped with a linear laser thermal excitation source and a high-resolution infrared thermal imager, which can perform thermal excitation and thermal image acquisition on the surface of a glass curtain wall glued structure , according to the temperature distribution of the glass curtain wall glued structure to judge the defects.

[0034] like figure 1 Shown is the active infrared thermal wave detection method process for glass curtain wall glued structural damage, including...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap