Single-phase capacitor switching switch

A capacitive switch, single-phase technology, applied in the field of switches, can solve the problems of intelligent split compensation and only co-compensation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

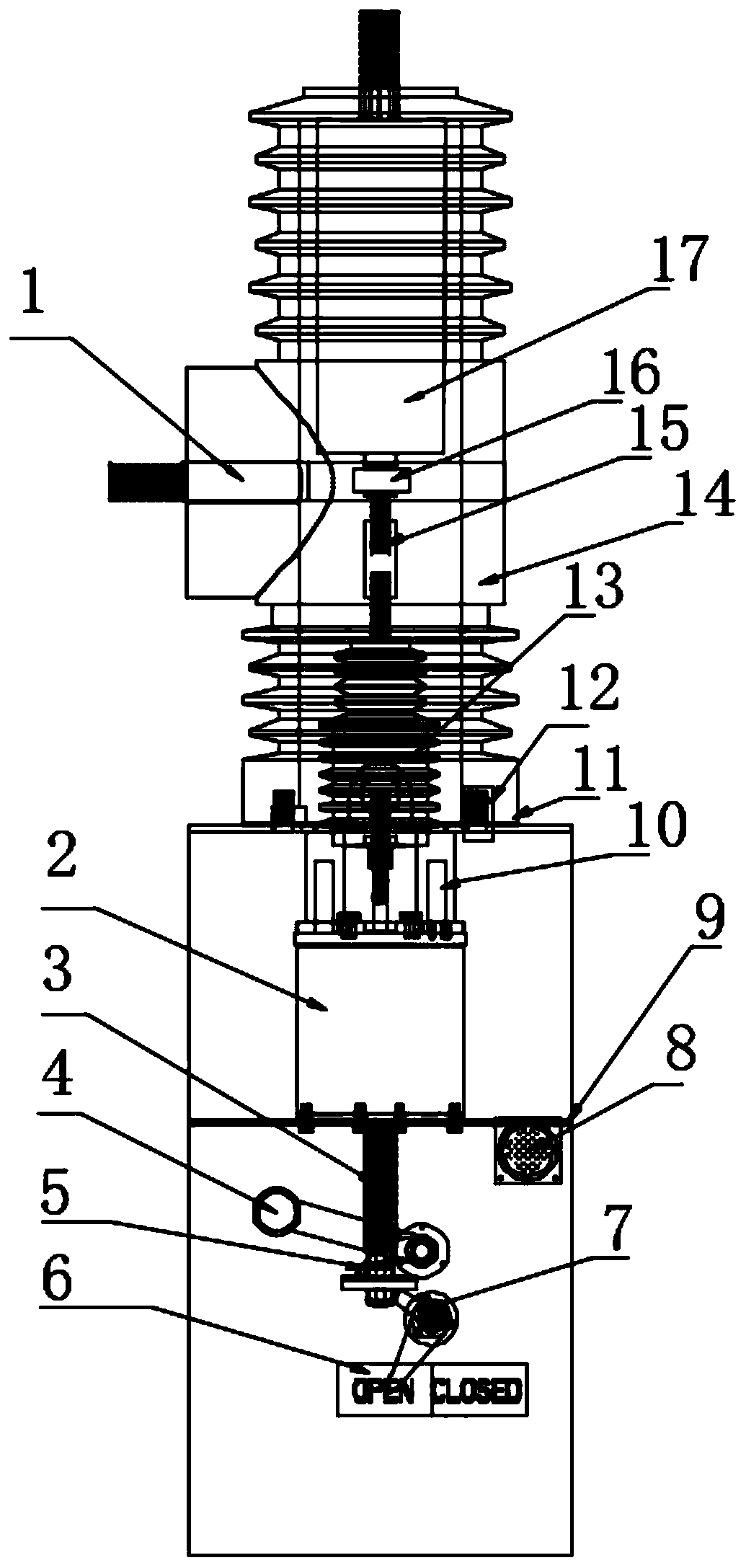

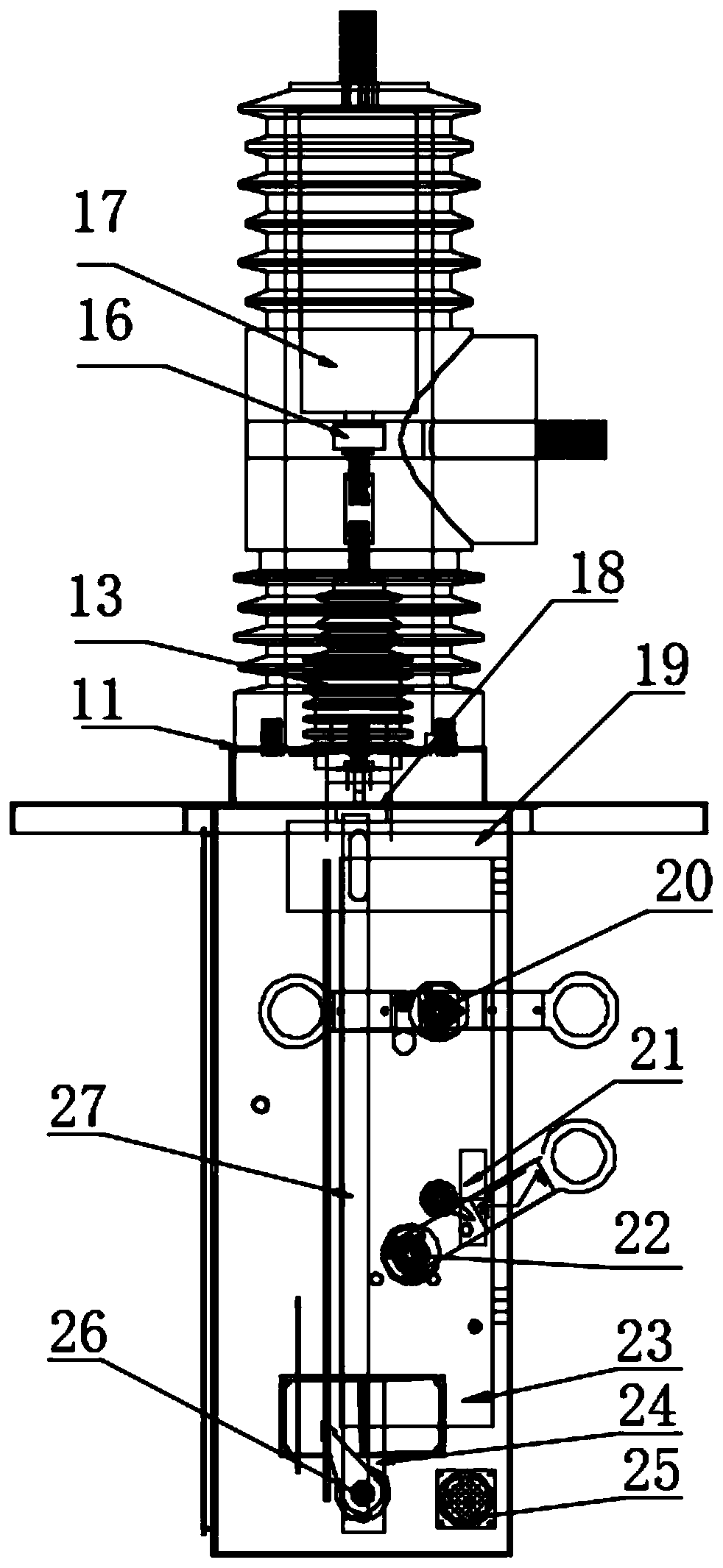

[0023] Such as figure 1 with figure 2 As shown, in the embodiment of the present invention, a single-phase tangential capacitance switch includes a lower housing and an insulating cylinder 14, the insulating cylinder 14 is installed on the upper side of the lower housing, between the lower housing and the insulating cylinder 14 An insulating pull rod 13 is installed, and a conductive clip 16 is installed inside the insulating tube 14. A vacuum tube 17 is installed on the insulating tube 14 at the upper end of the conductive clip 16. The vacuum tube 17 can realize high-voltage load, short-circuit breaking, and a permanent magnet structure is installed inside the lower shell. Coil 2, the permanent magnet structure coil 2 can move up and down quickly after being energized, the permanent magnet structure coil 2 is connected with the opening handle 4 and the opening lever 5 through the first opening spring 3, the first opening spring 3 is used for manual opening Provide the verti...

Embodiment 2

[0027] A single phase cut capacitive switch such as figure 1 with figure 2 As shown, the embodiment of the present invention is further limited on the basis of embodiment 1.

[0028] Further, preferably, an insulating rubber pad 11 is installed at the lower end of the insulating pull rod 13, and a pole positioning hole 12 is opened on the insulating rubber pad 11, and a connector 18 is installed at the lower end of the insulating rubber pad 11, and the lower housing at the lower end of the connector 18 The inner cooperating main shaft 27 is provided with a rotating shaft limiting ring 19 .

[0029] Further, preferably, the insulating cylinder 14 is equipped with an outgoing conductive rod 1, the outgoing conductive rod 1 is inserted and fixed on the insulating cylinder 14, the inner side of the outgoing conductive rod 1 is connected to a conductive clip 16, and a connector nut 15 is installed on the lower end of the conductive clip 16. .

[0030] Further, preferably, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com