Lithium-ion battery anode material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as cracking, pulverization, fading, and no special mention, so as to increase activity and capacity, improve cycle life, Excellent chemical stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

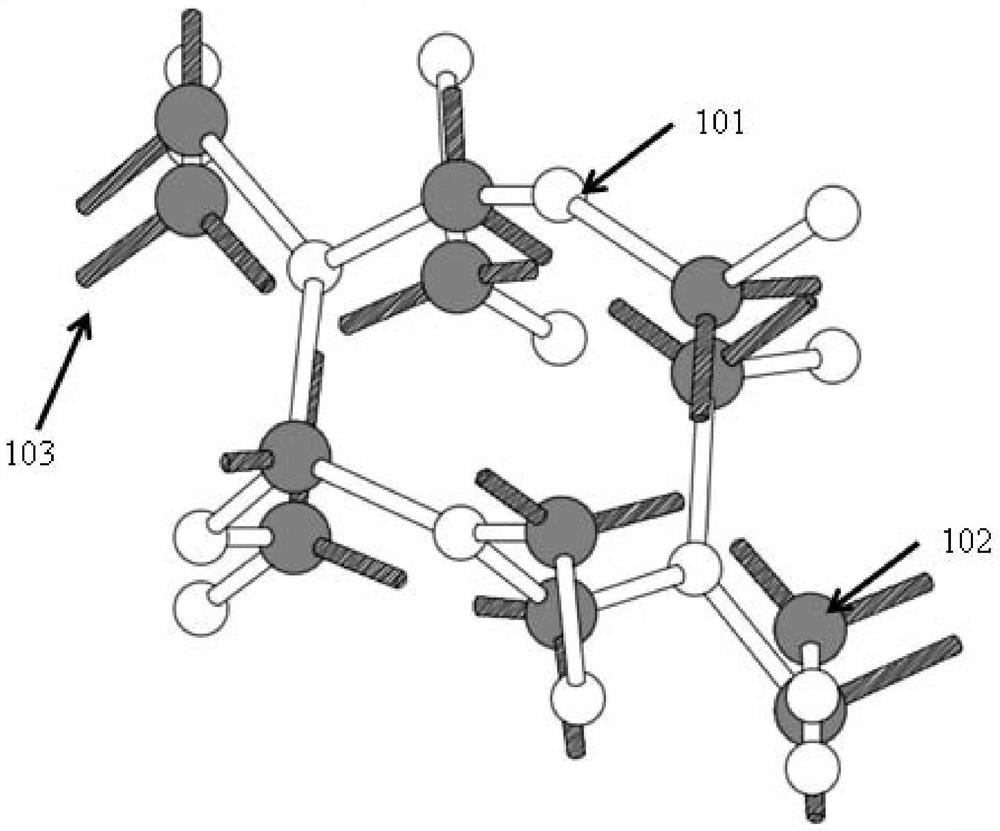

[0040] The first embodiment, to contain high content (for example 70wt% or more) β-phase silicon nitride (β-Si 3 N x ) silicon nitride 201 is the main negative electrode material, and the negative electrode material is prepared by utilizing its dangling bond 103 and the characteristics of its crystal layered structure.

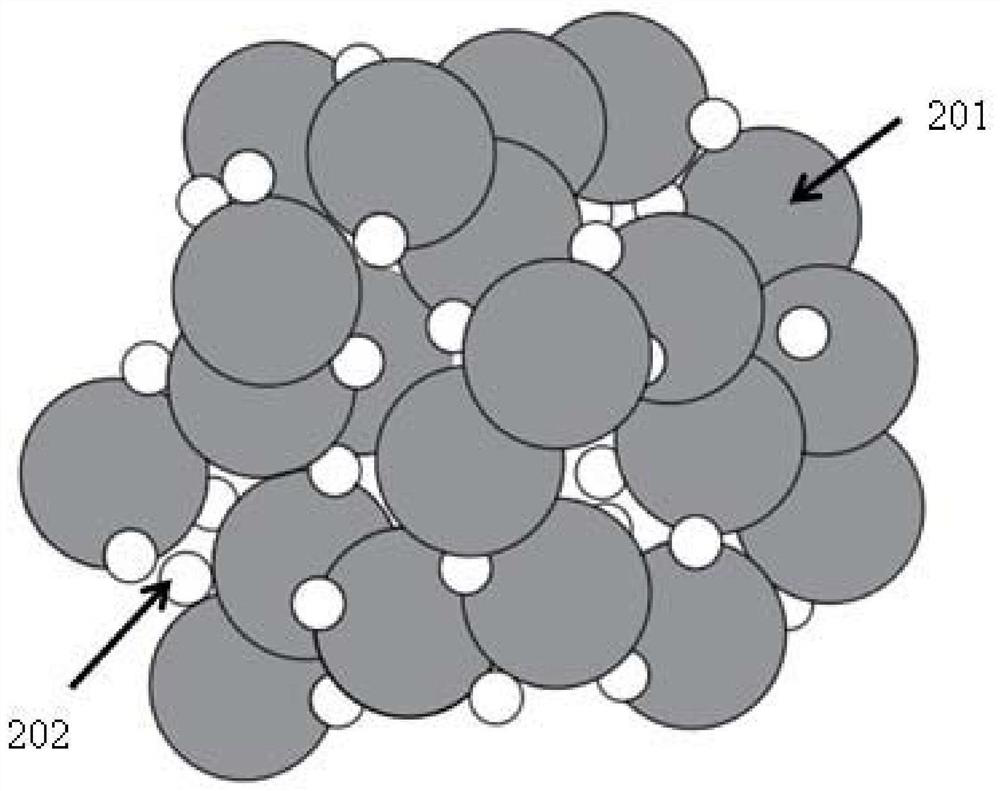

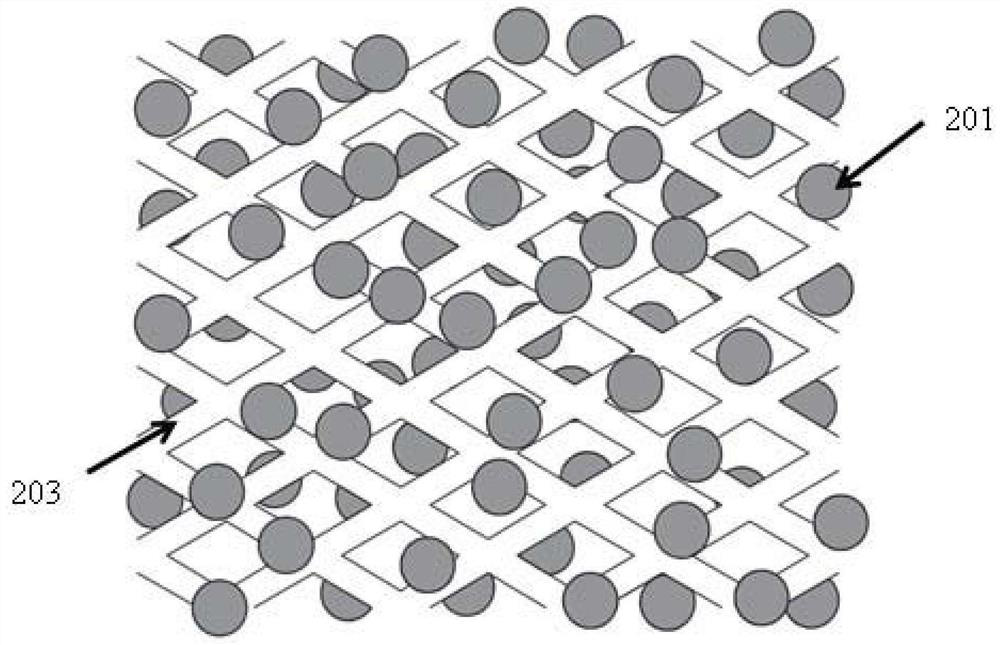

[0041] Second embodiment, such as figure 2 As shown, silicon nitride 201 and graphite particles 202 are physically mixed to prepare the negative electrode material. If the content of β-phase silicon nitride 201 is large, the graphite will increase the overall conductivity of the negative electrode, and its capacitance will be expressed as β-phase nitrogen The capacitance of the silicon oxide 201 is present; if the content of graphite particles 202 is high, the β-phase silicon nitride 201 has the effect of increasing the capacitance of the graphite particles 202 and stabilizing the structure, and modifies the composition of the negative electrode material of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com