Integral single-segment pre-assembling method for anchoring platform

A single-section, anchor platform technology, which is applied in transportation and packaging, ship parts, ships, etc., can solve the problems of inconvenient docking construction of anchor chain tubes, difficulty in controlling the accuracy of anchor chain tubes in anchor platform positioning, etc., and shorten the total assembly time. cycle, avoid damage, and reduce the difficulty of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail:

[0025] The present invention relates to an integral single-section pre-installation method of an anchor platform, comprising the following steps:

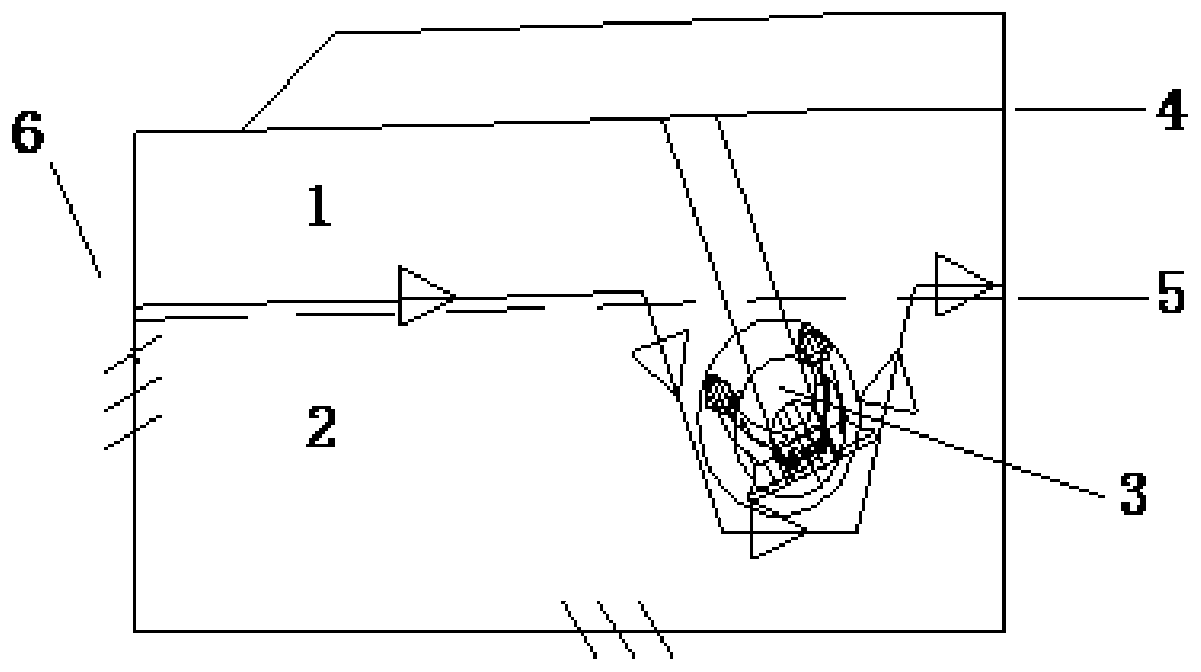

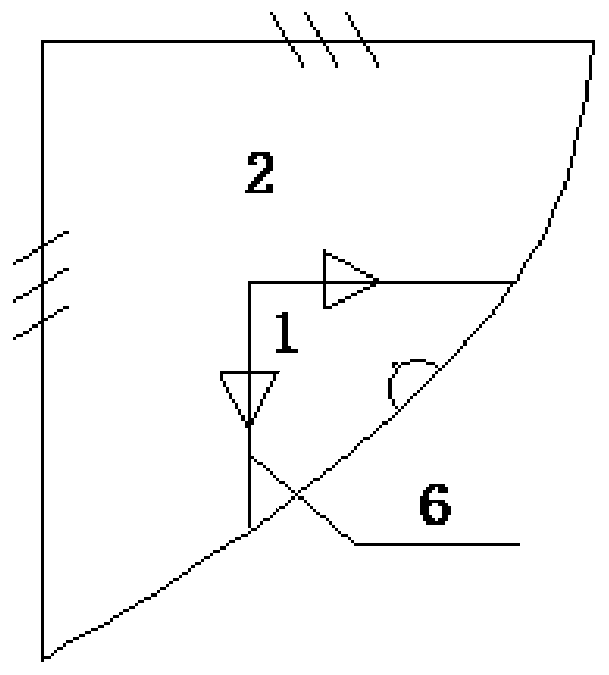

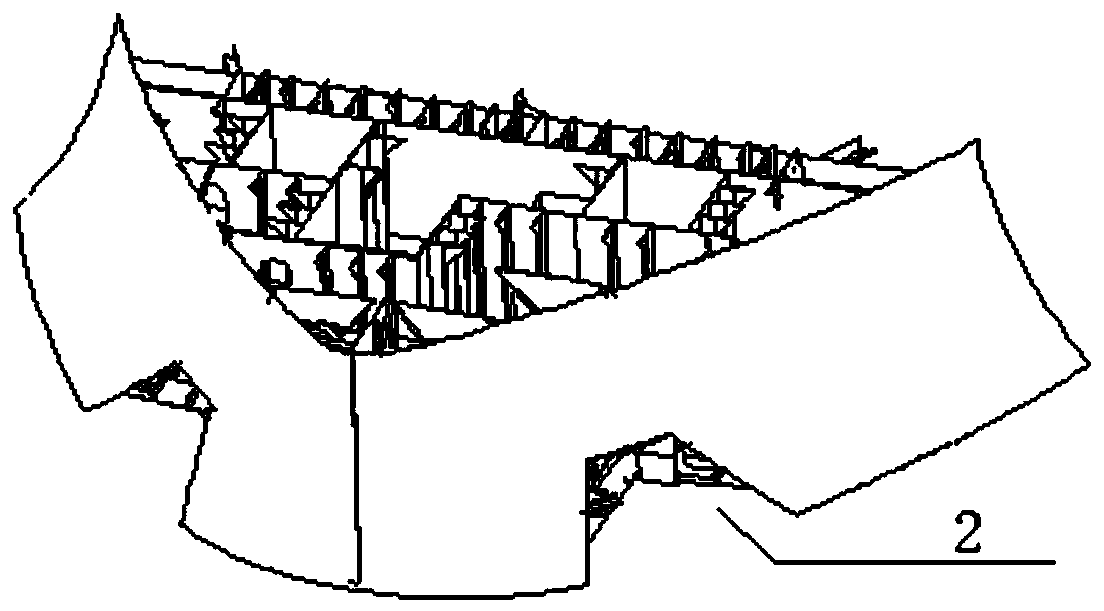

[0026] In the first step, the hull of the bow is divided into upper section 1 and lower section 2. At the same time, the anchor abutment, the anchor lip and the anchor chain drum are assembled into the whole anchor abutment 3 . The upper section 1 includes the forecastle deck 4 and the position corresponding to the installation of the whole anchorage 3, wherein the installation position of the whole anchorage 3 includes the place where the upper part is connected with the forecastle deck 4, and also includes the main part below the forecastle deck 4. Where deck 5 sections connect. The lower section 2 includes the main deck 5 with the removal of the entire anchorage installation location. like figure 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com