Water floating system

A unit connection and array technology, applied in floating buildings, ship parts, anchoring arrangements, etc., can solve the problems of insufficient utilization of the site, high cost, insufficient use of anchoring devices, etc., to meet the needs of special use, improve Safety and stability, the effect of increasing the utilization of the site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

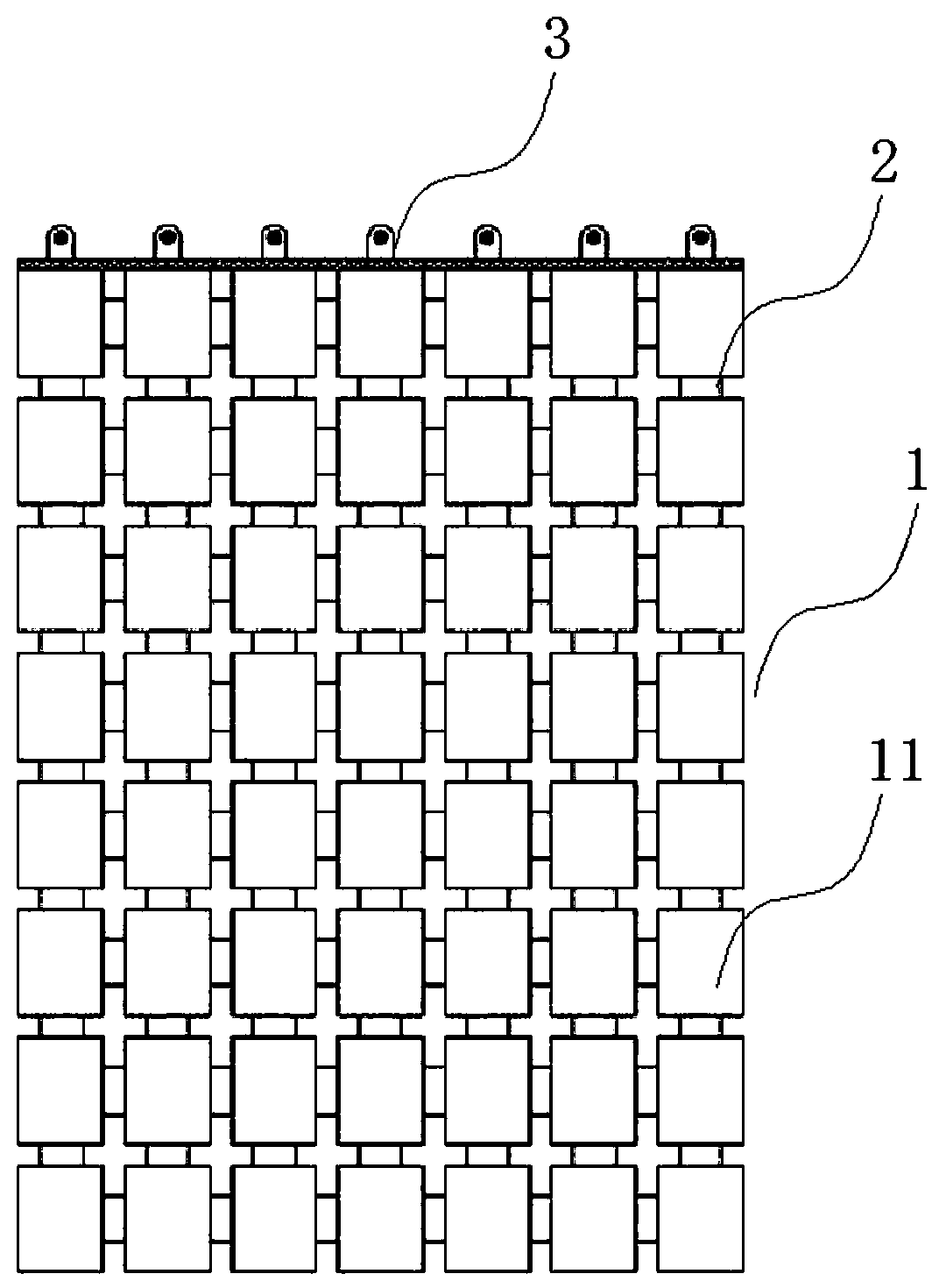

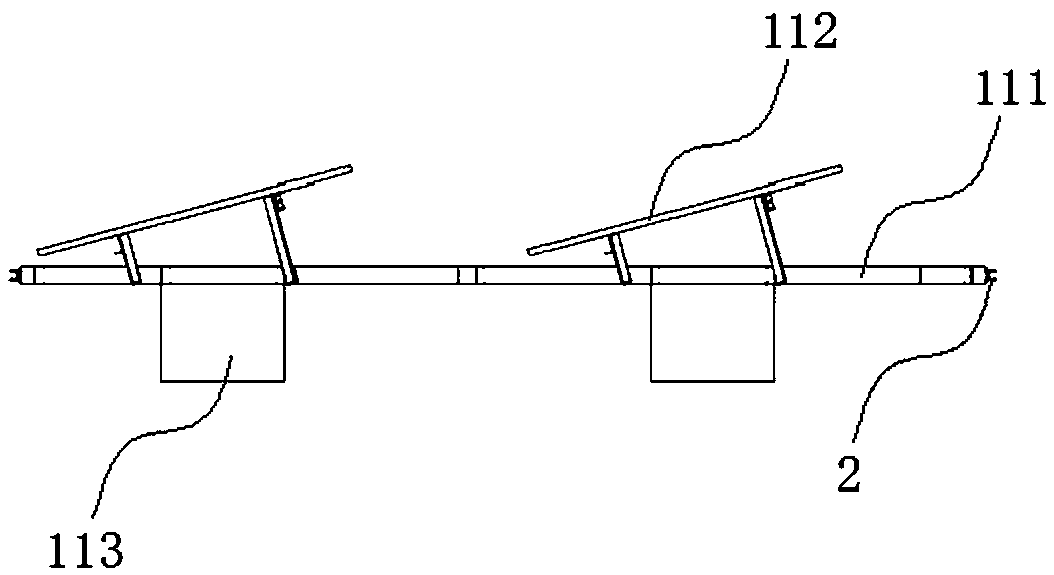

[0037] see figure 1 and figure 2 , a floating system on water, comprising a rectangular floating array 1, a connecting device 2 and an anchoring device 3, and a plurality of floating units 11 of the floating array 1 are arranged in a rectangular array. The floating unit 11 includes a rigid platform 111 of truss structure made of metal material arranged horizontally, several photovoltaic modules 112 are installed above the rigid platform 111 , and several floating blocks 113 are installed below the rigid platform 111 .

[0038] Two adjacent floating units 11 are connected by at least two connecting devices 2 arranged at intervals, and the connecting devices 2 are connected on the side of the rigid platform 111 of the floating units 11, preferably, between two adjacent floating units 11 The connecting device 2 between them is located on the same level as the rigid platform 111 of the floating unit 11. The connecting device 2 allows two adjacent floating units 11 to be displaced...

Embodiment 2

[0046] A water floating system includes a rectangular floating array 1, a connecting device 2 and an anchoring device 3, and a plurality of floating units 11 of the floating array 1 are arranged in a rectangular array. The structures of the floating unit 11 and the anchoring device 3 in the second embodiment are the same as those of the floating unit 11 in the first embodiment.

[0047] Two adjacent floating units 11 are connected by at least two connecting devices 2 arranged at intervals. The connecting device 2 is connected to the side of the rigid platform 111 of the floating unit 11. The connecting device 2 allows two adjacent floating units 11 to The relative displacement in the horizontal direction and the vertical direction can occur without colliding with each other, and the deflection angle of two adjacent floating units 11 in the vertical direction is limited.

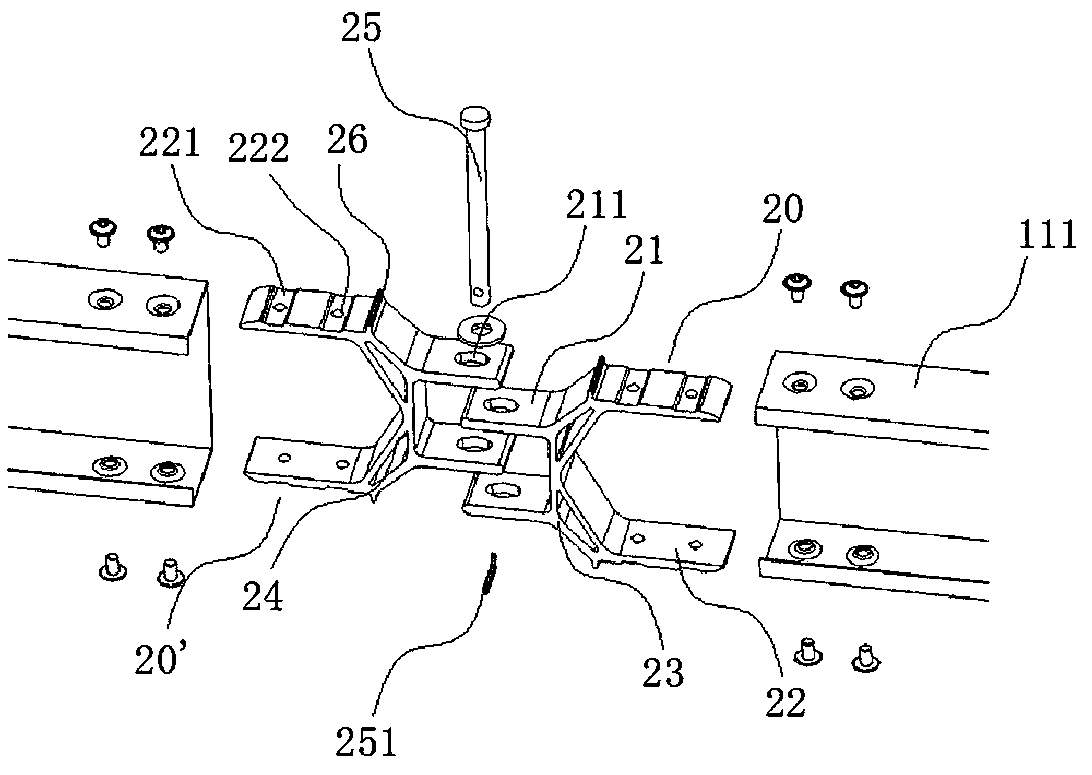

[0048] Specifically, see Figure 8 and Figure 9 , The connection device 2 includes a first unit connect...

Embodiment 3

[0054] see Figure 10 , a floating system on water, comprising an anchoring device 3 and a floating array 1 distributed on the outer periphery of the anchoring device 3 , a plurality of floating units 11 of the floating array 1 are radially distributed on the outer periphery of the anchoring device 3 , between two adjacent floating units 11 They are connected by at least two connecting devices 2 arranged at intervals, and the connecting devices 2 are connected to the floating unit 11 . The anchoring device 3 in the third embodiment is basically the same in structure as the anchoring device 3 in the second embodiment, except that the main hoop 32 is connected to the adapter assembly 31 through several connecting rods.

[0055] The structure of the floating unit 11 in the third embodiment is the same as that of the floating unit 11 in the first embodiment. The connecting device 2 in the third embodiment may have the same structure as the connecting device 2 in the first or seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com