A kind of phase change heat insulation material and preparation method thereof

A technology of heat insulation materials and phase change materials, applied in the direction of heat exchange materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems involving less application fields, achieve effective heat insulation and wide application Foreground, the effect of delaying the heat transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Preparation of Phase Change Thermal Insulation Material

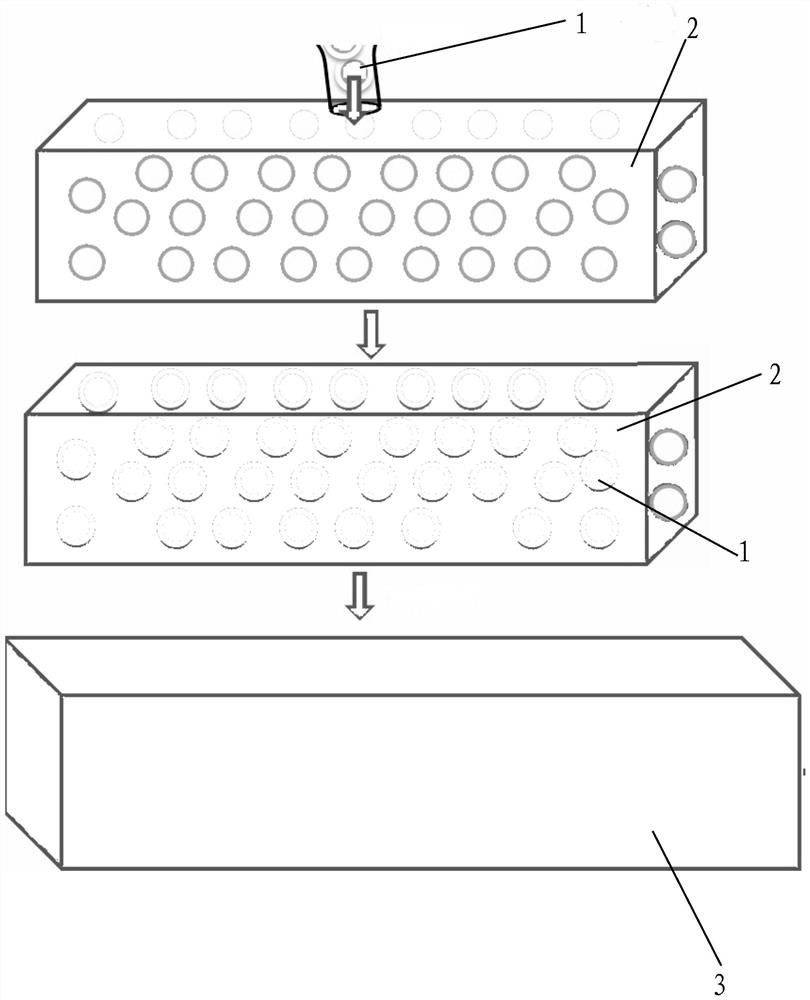

[0016] The core material 1 was prepared by physical blending according to the ratio of 70% phase change paraffin + 30% cetyl alcohol. Heat the prepared core material 1 at a certain temperature, and after it reaches a certain viscosity, follow the figure 1 As shown in the schematic diagram, it is poured into the polyurethane foam material 2, and finally it is sealed with a polyurethane potting compound 3 filled with alumina fibers.

Embodiment 2

[0017] Example 2: Practical application effect of phase change heat insulation material

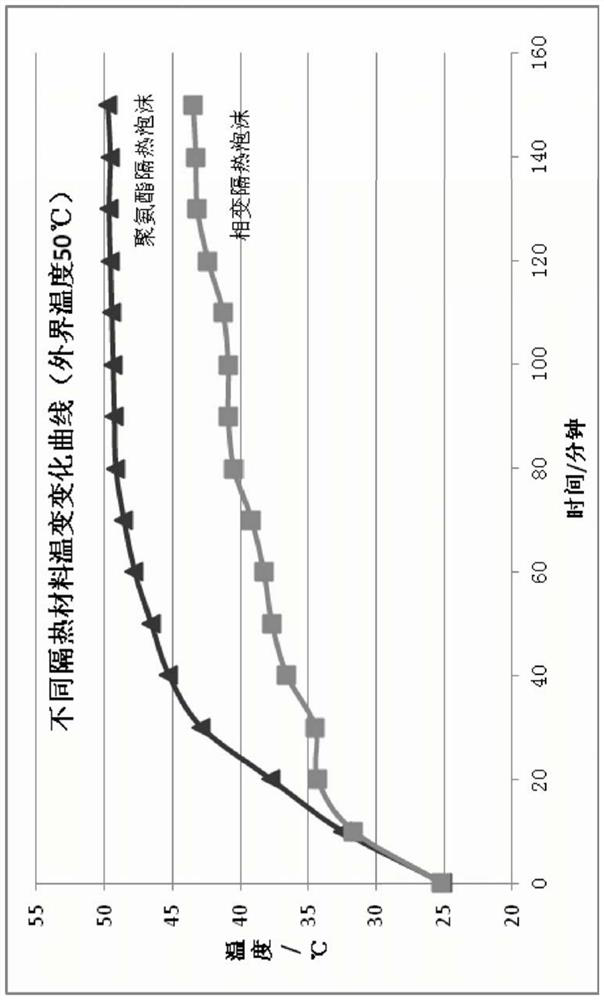

[0018] The prepared phase-change thermal insulation material was attached to the surface of the outdoor box, and compared with the commercial polyurethane thermal insulation foam material, the temperature change curve of the box is as follows: figure 2 shown. From figure 2 It can be seen from the figure that the thermal insulation effect of the test box using phase change thermal insulation foam material is obviously better than that of the control box using ordinary thermal insulation foam. At 50°C, the temperature of the control box was basically stable at about 40°C at 80 minutes, and at about 43°C at 130 minutes. Comparing the temperature curves of the test box and the control box at various ambient temperatures, the final stable temperature of the test box was higher than that of the control box. The temperature of the box is 5°C to 6°C lower. And as the ambient temperature incr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com