Movement mechanism of fishing net braiding machine

A motion mechanism and knitting machine technology, which is applied to braids, mechanical equipment, transmission devices, etc., can solve the problems of low transmission accuracy, complex structure, poor stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

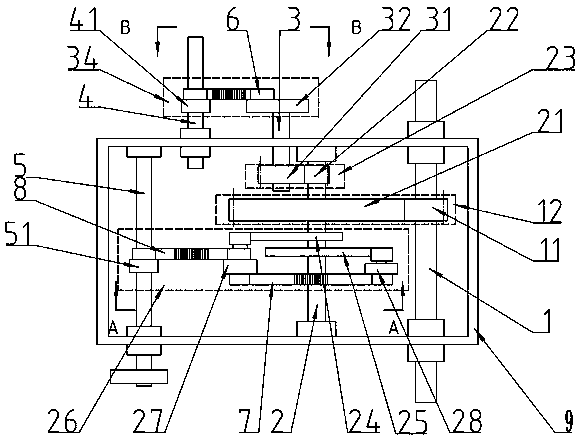

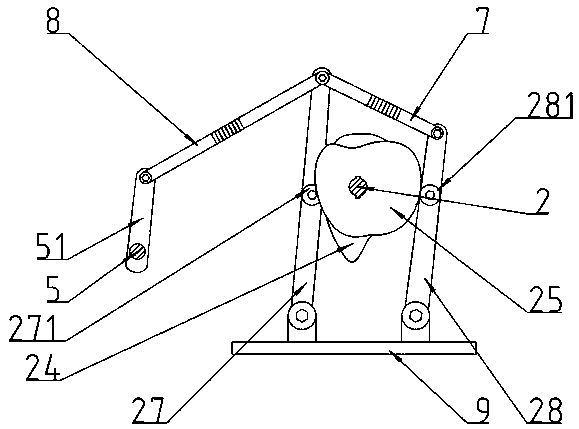

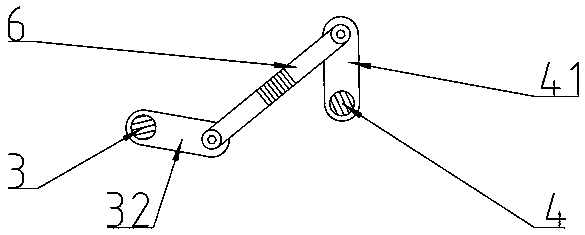

[0019] Such as figure 1 As shown, a kinematic mechanism of a fishing net knitting machine includes a box body 9, a driving shaft 1, a driven shaft a2, a driven shaft b3, a driven shaft c4, a driven shaft d5, a gear transmission mechanism a12, and a gear transmission mechanism b23 , link mechanism a34, link mechanism b26, cam a24, cam b25, wherein the drive shaft 1, driven shaft a2, driven shaft b3, driven shaft c4, driven shaft d5 are installed on the box 9 respectively . The driving shaft 1 is connected to the driven shaft a2 through a gear transmission mechanism a12. The driven shaft a2 is connected to the driven shaft b3 through a gear transmission mechanism b23. The driven shaft b3 is connected to the driven shaft c4 through a link mechanism a34. The driven shaft a2 is connected to the driven shaft d5 through a link mechanism b26. The cam a24 is sheathed on the driven shaft a2, connecting the driven shaft a2 and the link mechanism b26; the cam b25 is sheathed on the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com