A pressurization device and pressurization method suitable for single hydraulic props in underground coal mines

A single hydraulic prop and pressurization device technology, used in props/supports, mining equipment, earth-moving drilling, etc. Safe use and avoid the effect of live equipment work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

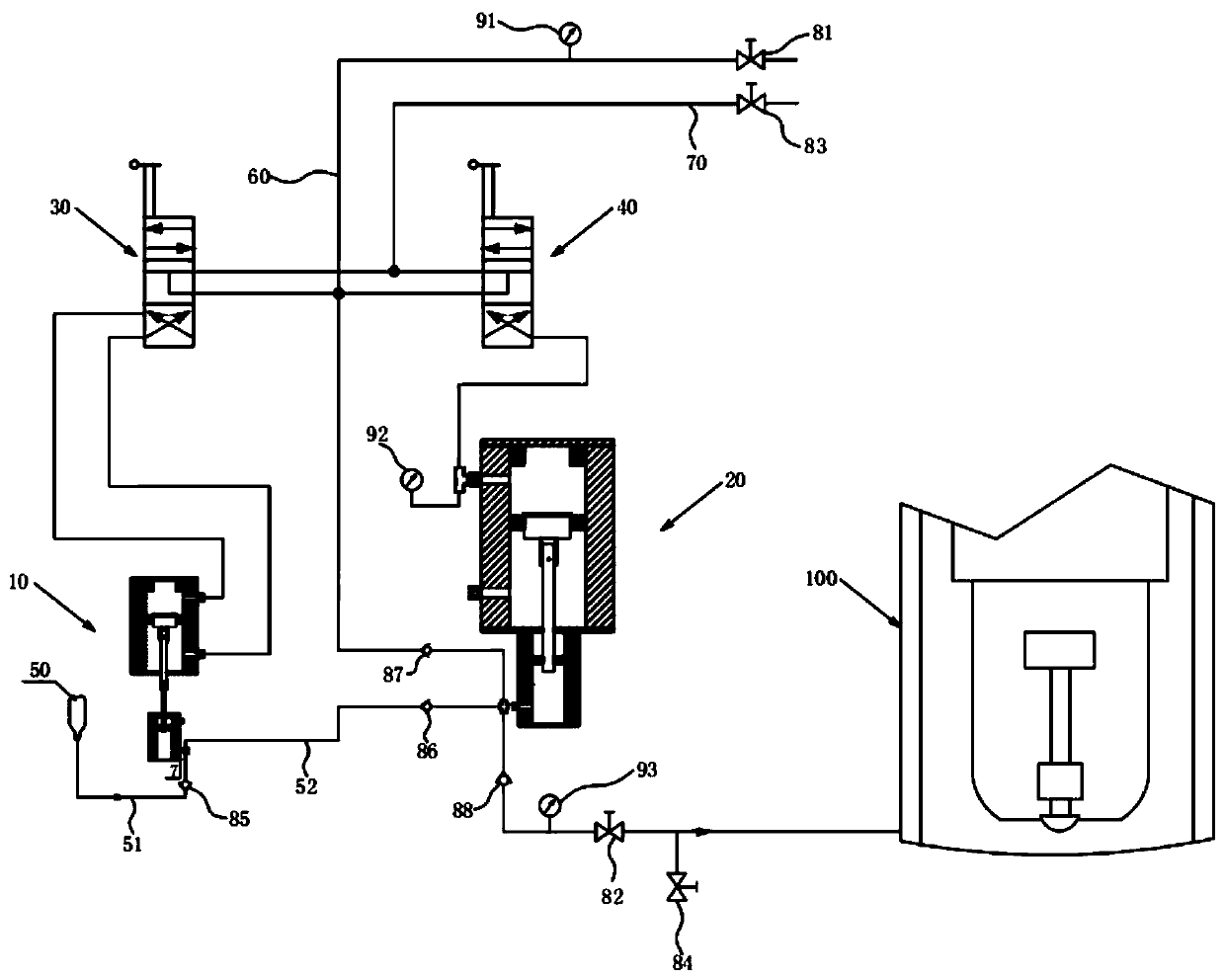

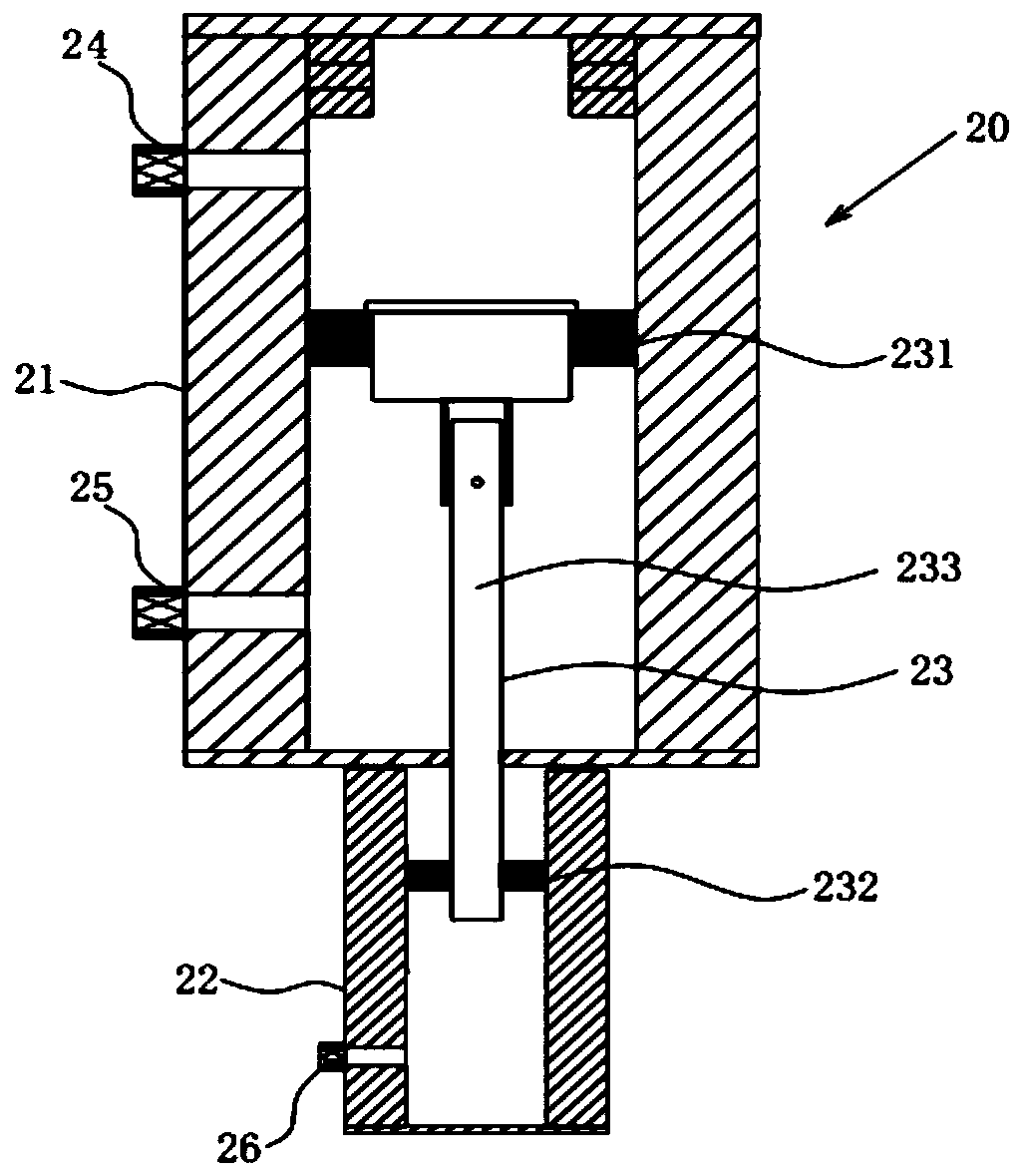

[0047] Such as Figure 1 to Figure 3 As shown, this embodiment provides a booster device suitable for a single hydraulic prop in an underground coal mine, which includes a first oil cylinder 10, a second oil cylinder 20, a first control valve 30, a second control valve 40, and a liquid storage container 50. Water inlet pipe 60, water return pipe 70, high-pressure cut-off valve A81, high-pressure cut-off valve B82, high-pressure cut-off valve C83 and multiple one-way valves.

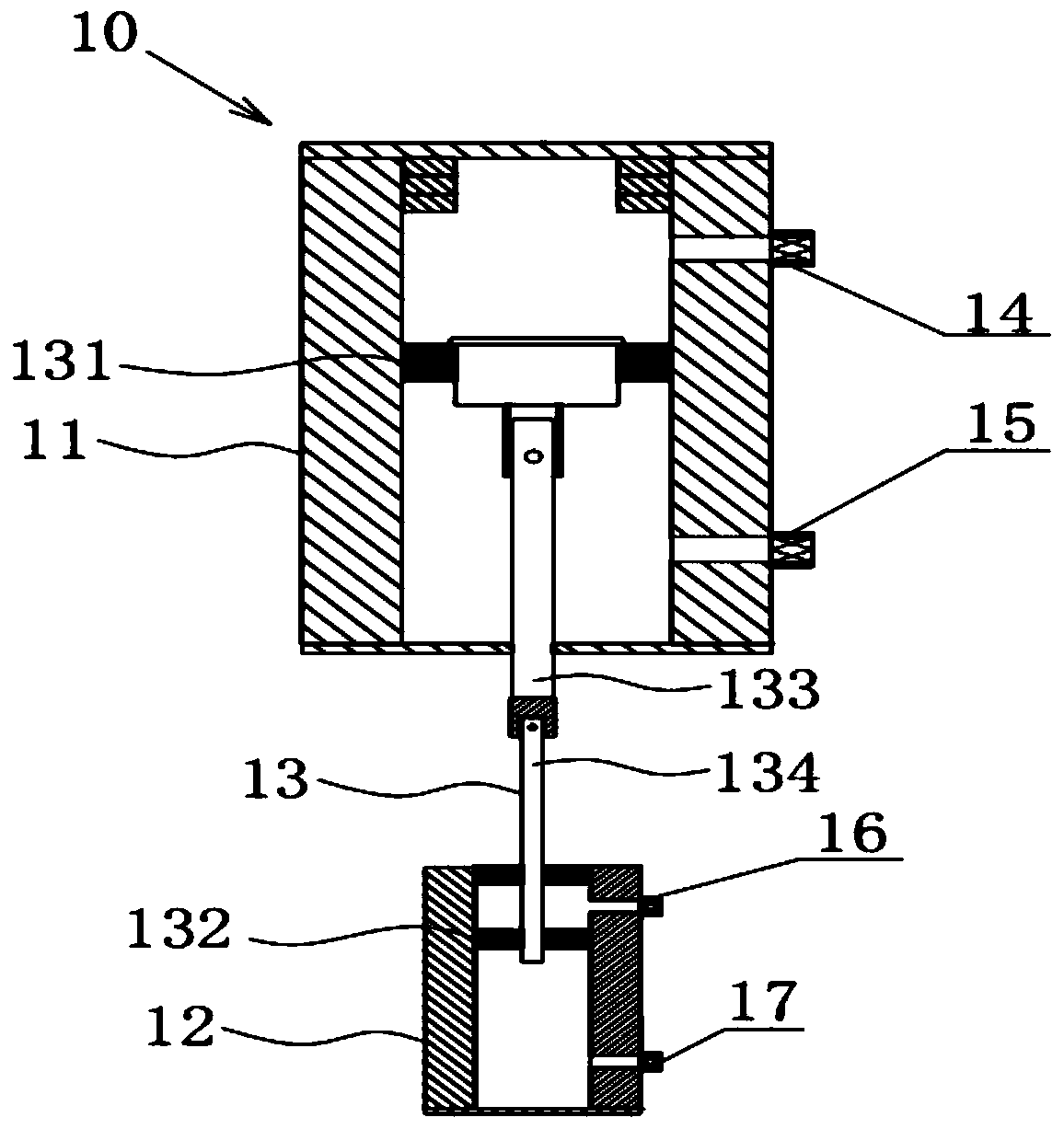

[0048] Such as figure 2 As shown, the first oil cylinder 10 includes an upper cylinder A11, a lower cylinder A12 and a piston rod A13, the inner diameter of the lower cylinder A12 cavity is smaller than the inner diameter of the upper cylinder A11 cavity, and the inner diameter of the piston rod A13 The two ends are slidably connected to the cavity of the upper cylinder A11 and the cavity of the lower cylinder A12, and the two ends of the piston rod A13 respectively separate the upper cylinder A11 and t...

Embodiment 2

[0067] This embodiment provides a method of using a booster device suitable for single hydraulic props in underground coal mines based on embodiment 1, which specifically includes the following steps:

[0068] S10, install and detect the secondary booster device;

[0069] S11. Connect the water inlet end of the water inlet pipe 60 to the downhole static pressure water pipe, connect the water outlet end of the water inlet pipe 60 to the single hydraulic prop 100, and connect the water outlet end of the return pipe 70 to the downhole drain pipe or drainage ditch;

[0070] S12, open the high-pressure cut-off valve A81, the high-pressure cut-off valve B82 and the high-pressure cut-off valve C83, and confirm that the static pressure water enters the solution cavity of the first control valve 30 and the second control valve 40;

[0071] In step S12, it can be determined whether the water inlet pipe 60 reaches 2.5MPa through the pressure gauge A91;

[0072] S20, injecting the emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com