Method for automatically converting down-hole main and auxiliary machine ventilating system into multi-stage machine station ventilating system

A technology of ventilation system, main and auxiliary fans, applied in mine/tunnel ventilation, earthwork drilling, special data processing applications, etc., can solve the problems of difficult management, large number of fans, and high energy consumption, and achieve convenient ventilation management The effect of reducing the number of fans and reducing the number of fans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

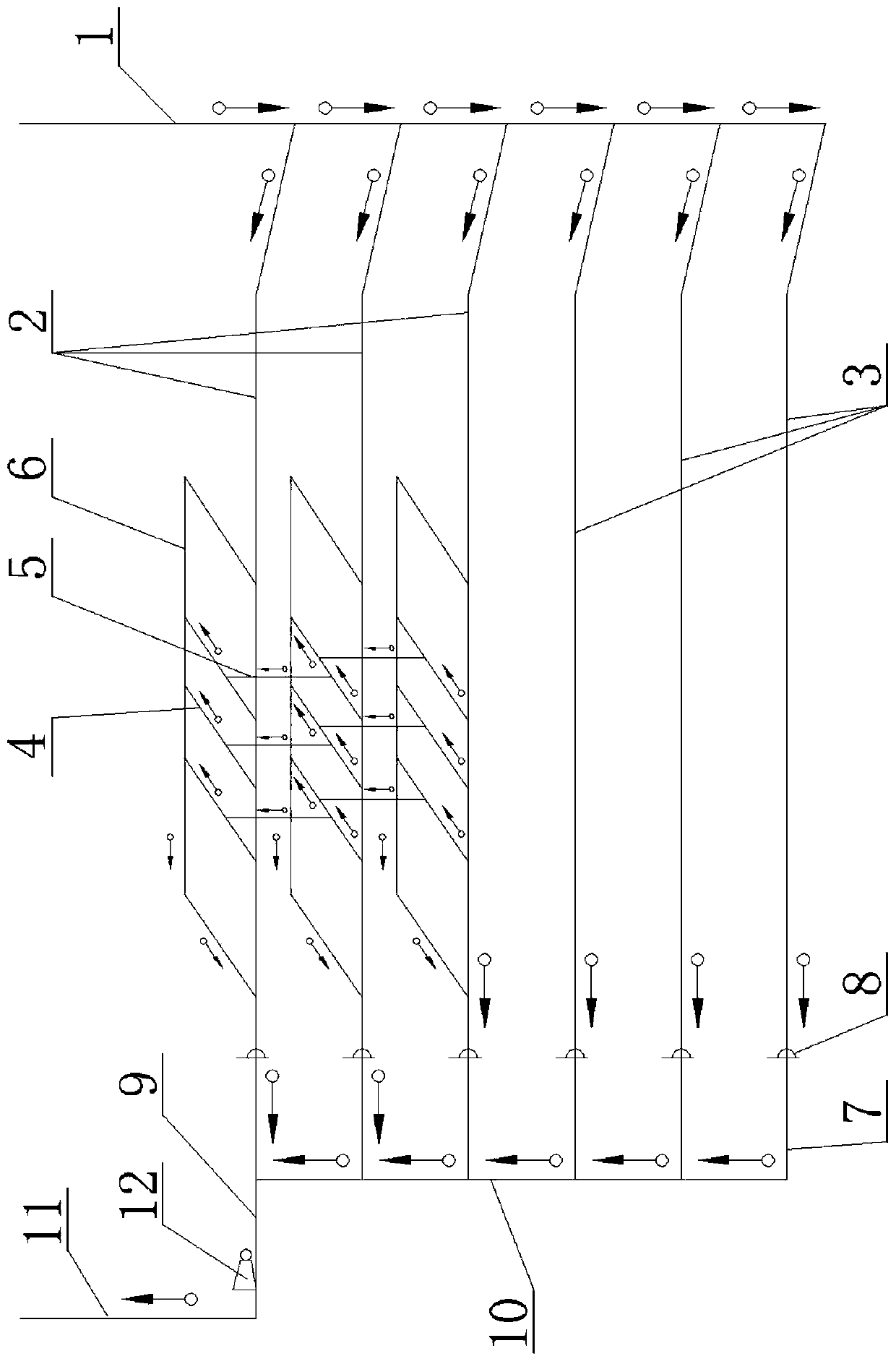

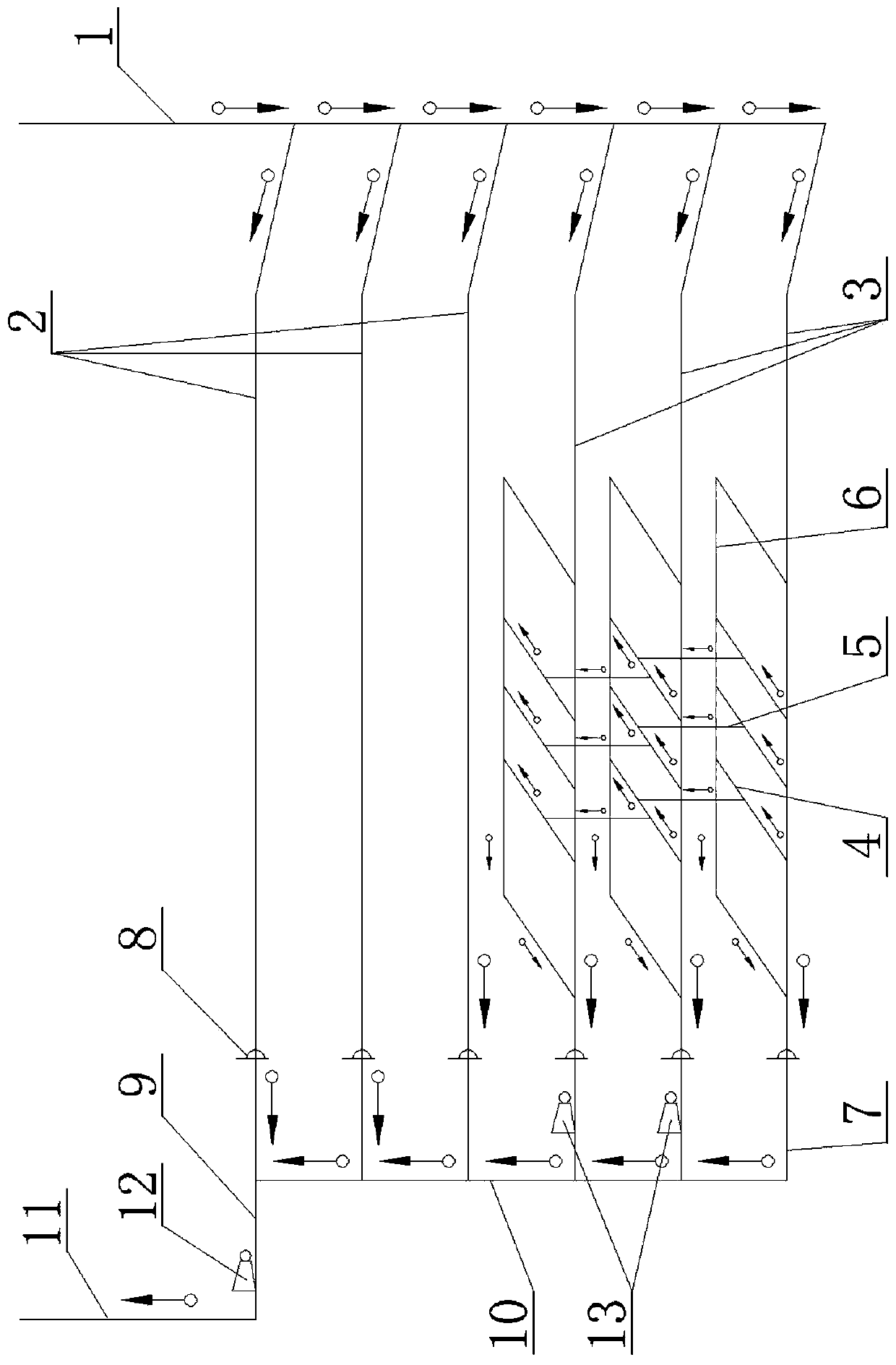

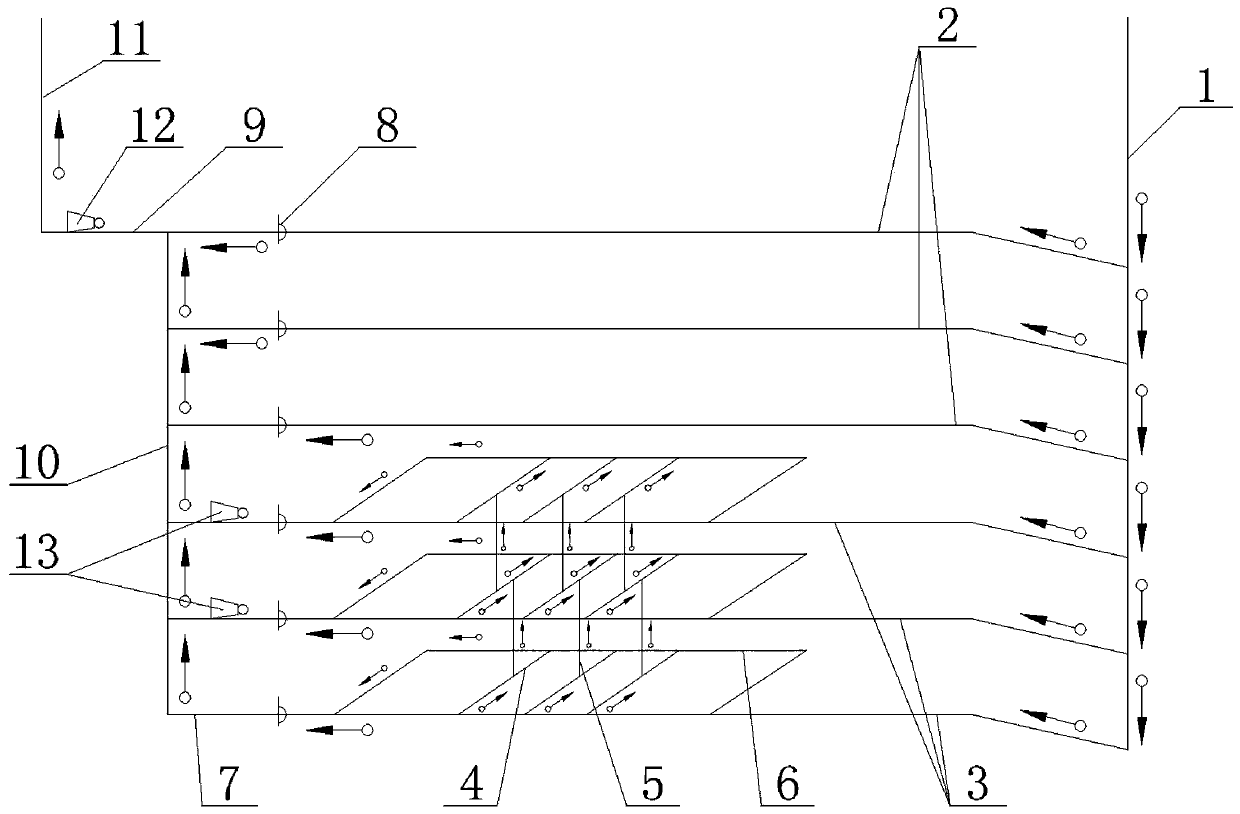

[0027] From figure 1 and figure 2 It can be seen that the method for automatic conversion of the underground main and auxiliary fans of the present invention to a multi-stage machine station ventilation system comprises the following steps:

[0028] S1. According to the mine capacity planning, combined with the mining depth, the entire production period is divided into two stages: the period of easy ventilation and the period of difficult ventilation

[0029] In the mine, there are air inlet shaft 1, air inlet lane in the middle section, piercing vein 4, stope air return patio 5, upper wall air return lane 6, middle air return stone gate 7, total air return stone gate 9, and reverse air shaft 10 And the return air shaft 11, the air inlet end of the middle air inlet lane is connected with the air inlet shaft 1, the upper wall return air lanes 6 are set one-to-one above each middle air inlet lane, and the piercing veins 4 are connected to the correspondingly arranged upper wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com