Structural layout of a light and small rocket engine

A rocket engine and structure layout technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc., can solve the problems of multiple disassembly and assembly of valves, low utilization rate of structural space, and poor compact layout structure. Flow resistance adjustment, beneficial to weight reduction and thermal protection, and beneficial to the effect of structural layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

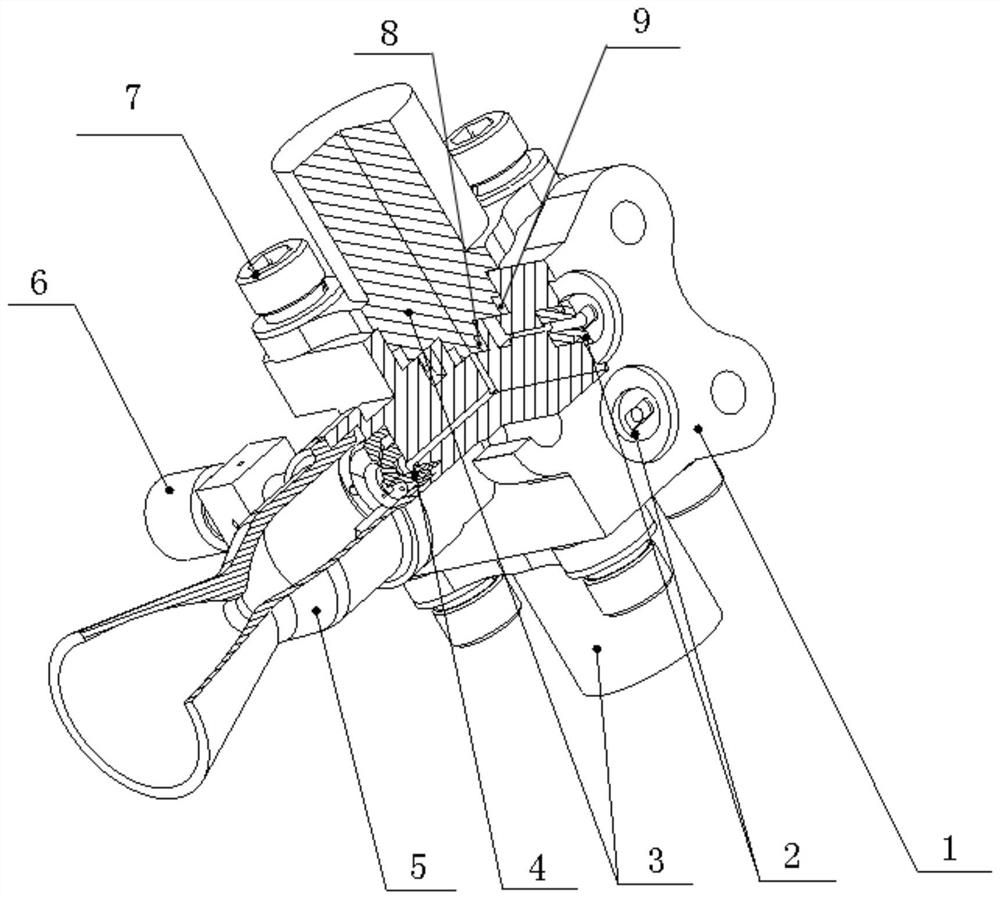

[0011] see figure 1 , The engine structure layout includes head shell module 1, throttle ring 2, propellant control valve 3, injector core 4, nozzle pipe 5, combustion chamber pressure nozzle 6, valve fastener 7, and internal leakage prevention The sealing ring 8 and the anti-leakage sealing ring 9 can realize the compact structure of the engine, which is beneficial to the modular integration of products.

[0012] The power system installation interface of the head shell module 1 is a plane flange interface, and multiple threaded holes are located on the same installation surface, and the middle area of the multiple threaded holes is the installation interface of the throttle ring 2 . The installation interface of the throttle ring 2 is an internal threaded hole. After the throttle ring 2 is installed, the smooth surface of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com