Double-nut propping and locking bolt

A technology of dead bolts and double nuts, which is applied in the direction of nuts, bolts, threaded fasteners, etc., and can solve problems such as easy loosening of bolts and fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

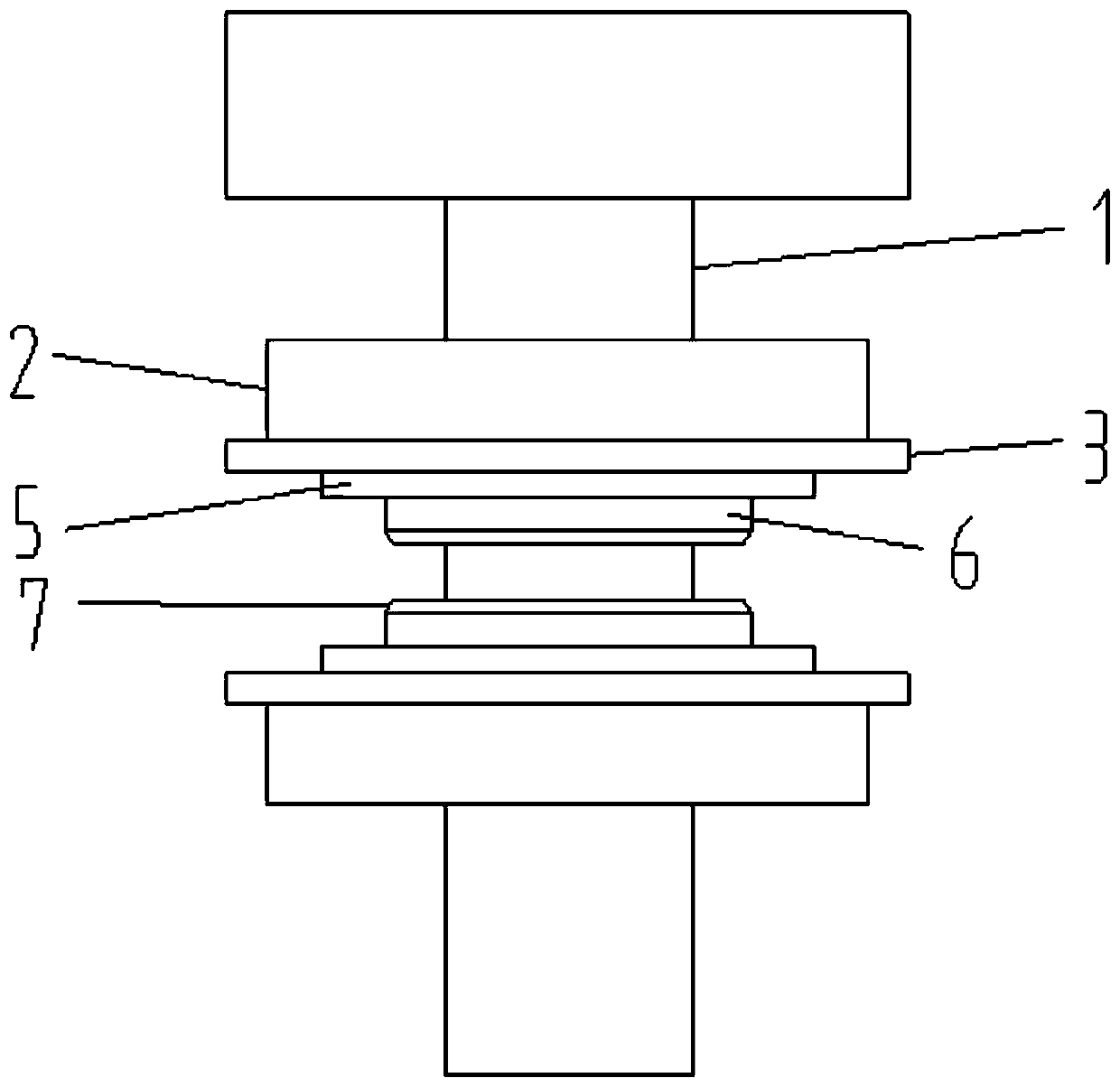

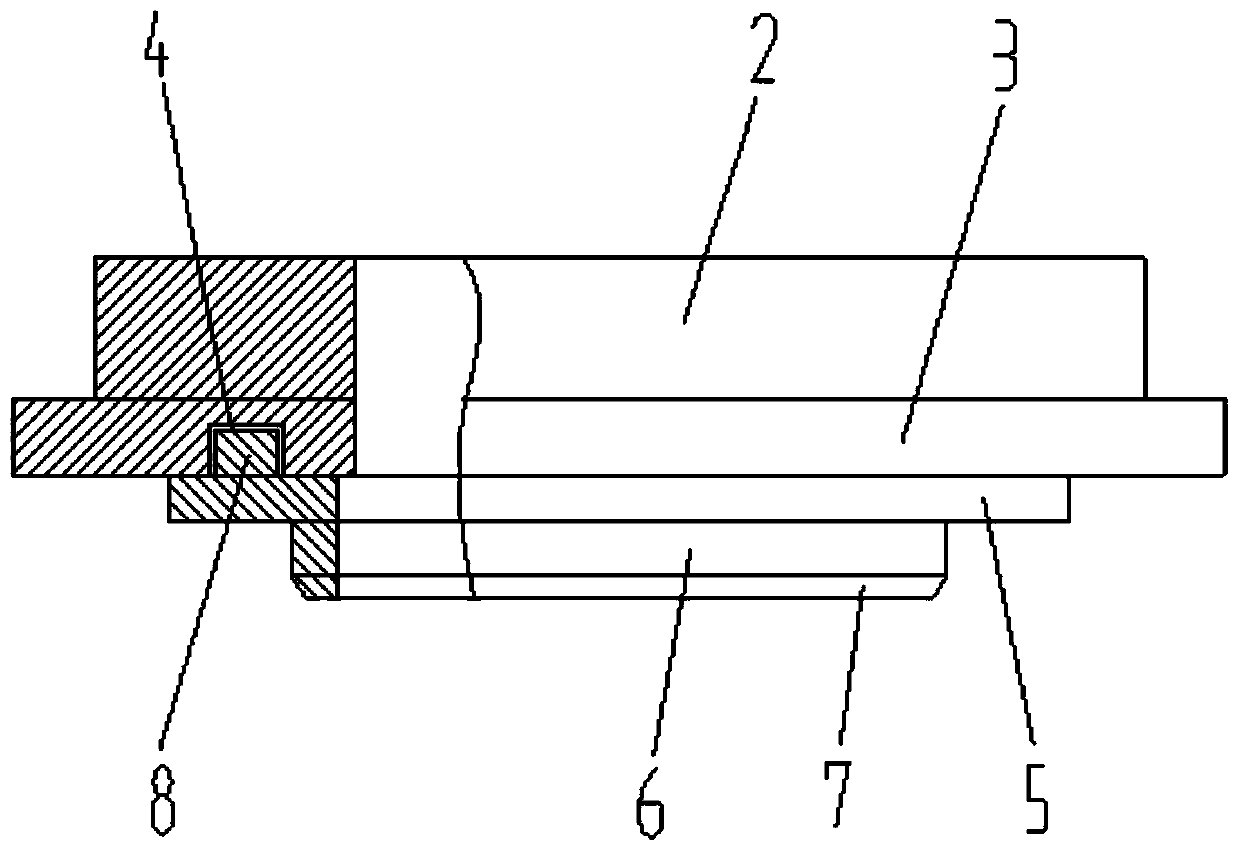

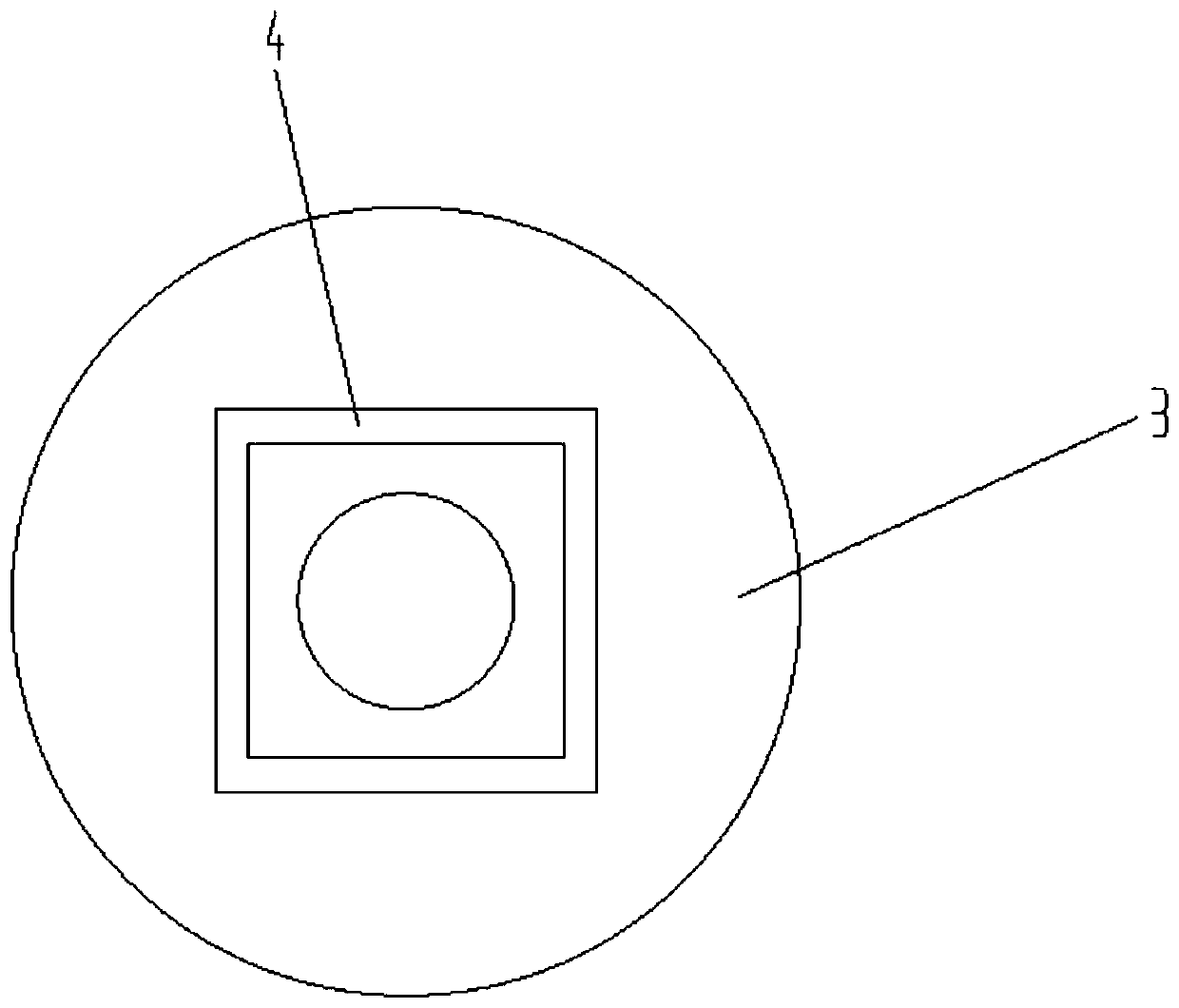

[0021] The double nuts of the present invention are pressed against the locking bolts, such as Figures 1 to 3 As shown, it includes a screw rod 1 and a nut 2. There are two nuts 2. A cylindrical sleeve 6 is radially fixed on one end surface of the nut 2. The end of the sleeve 6 forms a tapered lock edge 7 along the The locking edge 7 points to the direction of the nut 2, and the diameter of the outer circle corresponding to the outer surface of the locking edge 7 gradually increases from small to large. The inner hole diameter is larger than the nut 2 screw hole diameter;

[0022] The wall thickness of the sleeve 6 is smaller than that of the nut 2 .

[0023] The working principle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com