High temperature and high pressure resistant compensator

A high-voltage compensation and high-temperature-resistant technology, which is applied in the field of compensators, can solve problems such as safety concerns, reduced maintenance workload, and bellows rupture and failure, and achieve high reliability, long service life, and overcome aging and regular maintenance problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described with reference to the drawings and specific embodiments, but the present invention is not limited to these embodiments.

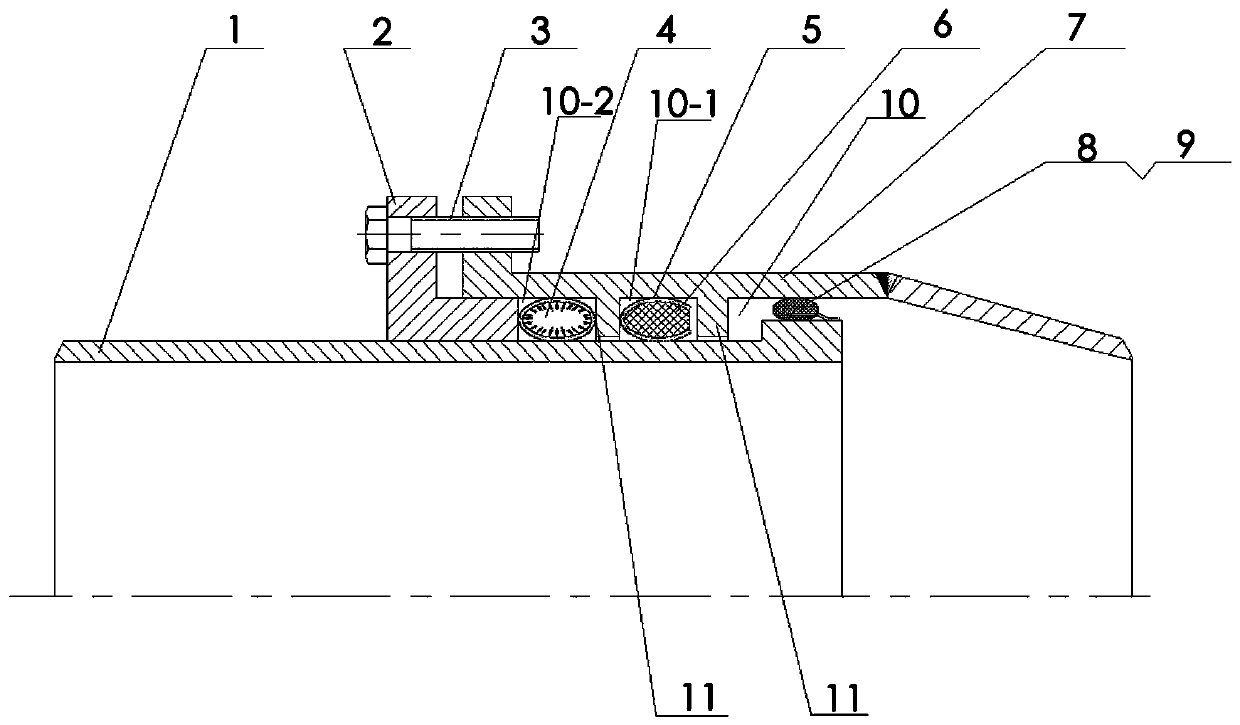

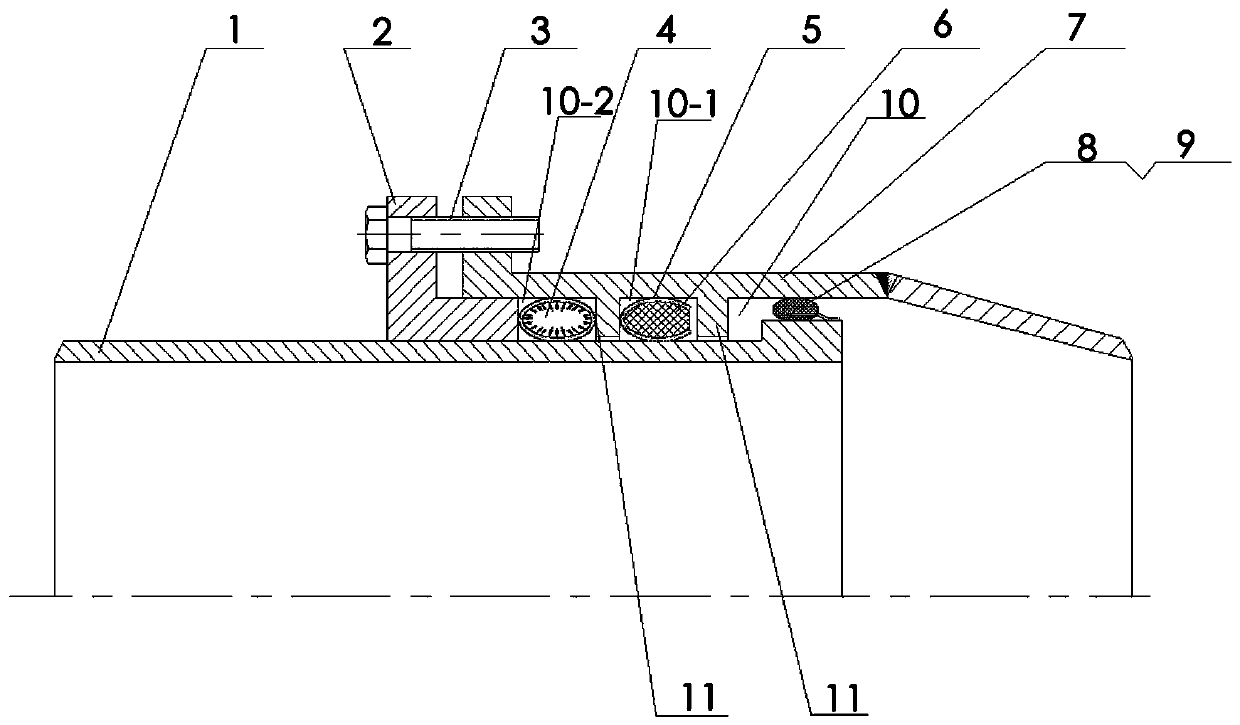

[0013] Such as figure 1 As shown, a high temperature and high pressure compensator includes an outer tube 7 sleeved on the outside of the core tube 1, an annular channel 10 is provided between the outer tube 7 and the core tube 1, and the outer tube 7 and the core tube 1 can slide relatively. The compensator also includes a gland 2, a retaining ring 11, an annular boss 12, a fixing piece, an inflatable metal O-shaped sealing ring 4, a C-shaped metal sealing ring 5 filled with ceramic fibers 6, and a wire mesh dustproof sealing ring 8. The gland 2 is sleeved on the outside of the core tube 1 and fixed on the end of the outer tube 7 by a fixing piece. One end of the gland 2 extends into the annular channel 10. The fixing piece can be in the form of welding or pressing bolts. When using compression bolts for connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com