Production device for natural dry casing

A production device and casing technology, applied in drying, drying machine, processing animal intestines, etc., can solve the problems of affecting the efficiency and appearance of sausage packaging, easy damage when taking off, and long drying time, etc., so as to facilitate large-scale promotion Production and use, shortened production and processing time, high integrity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

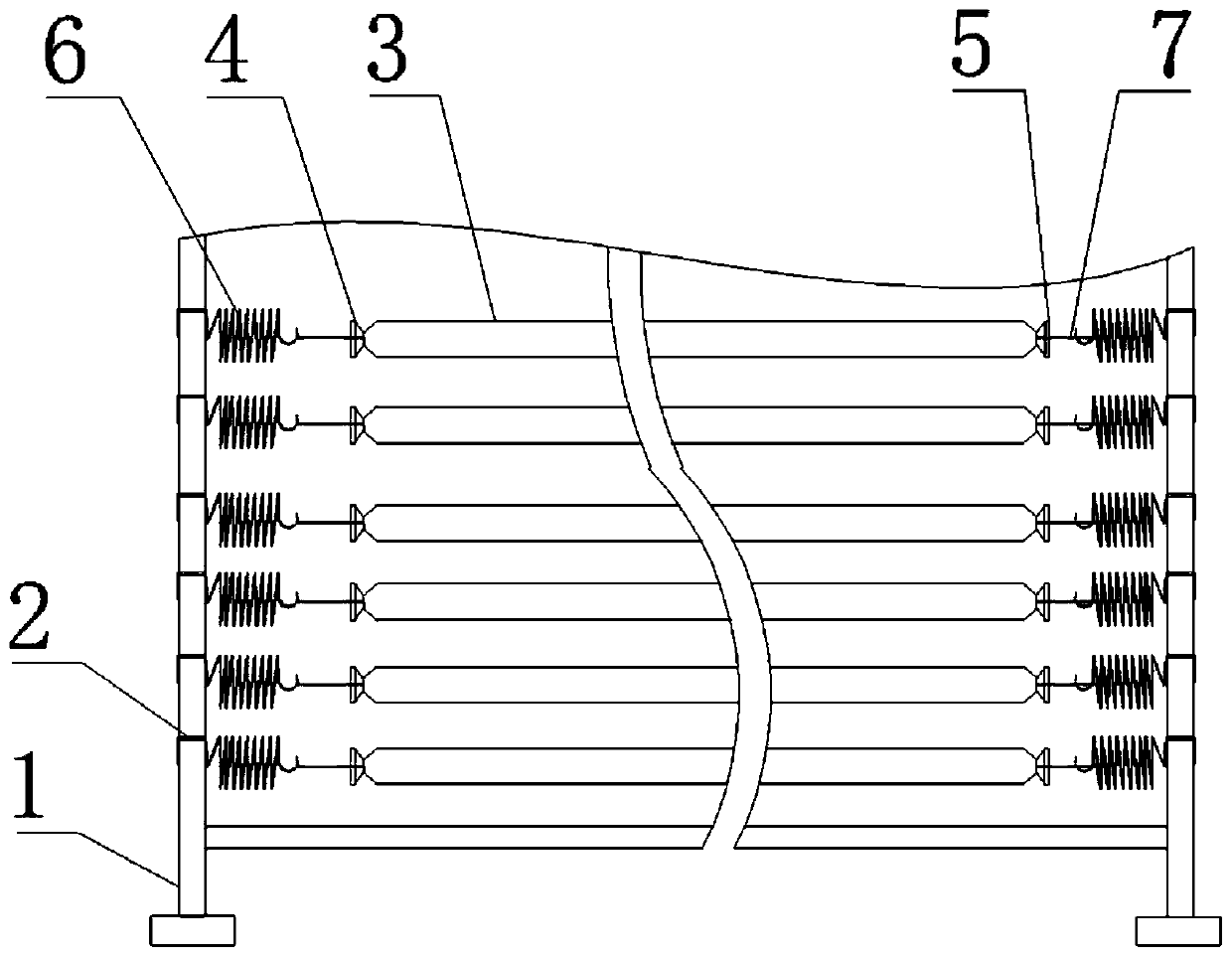

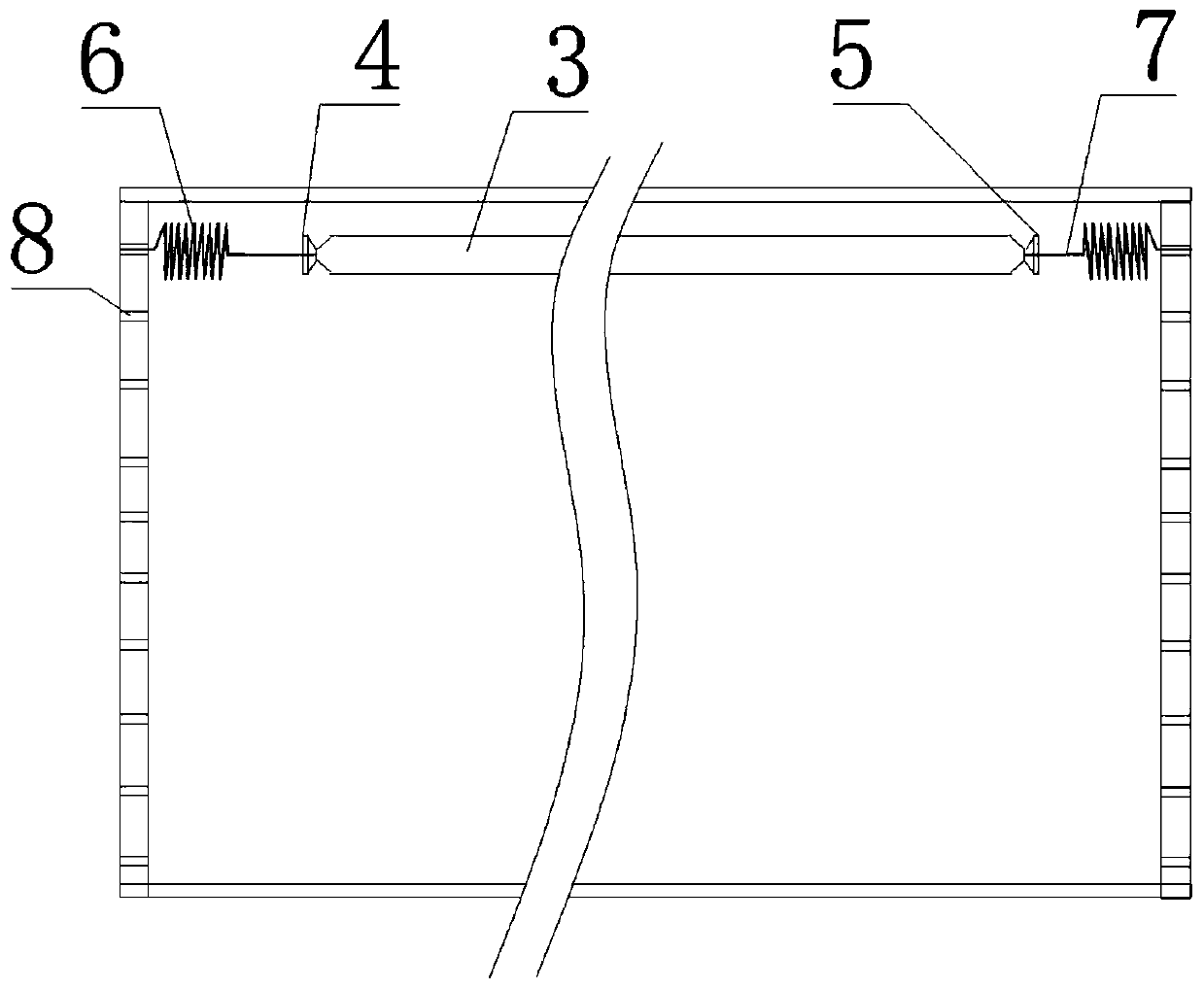

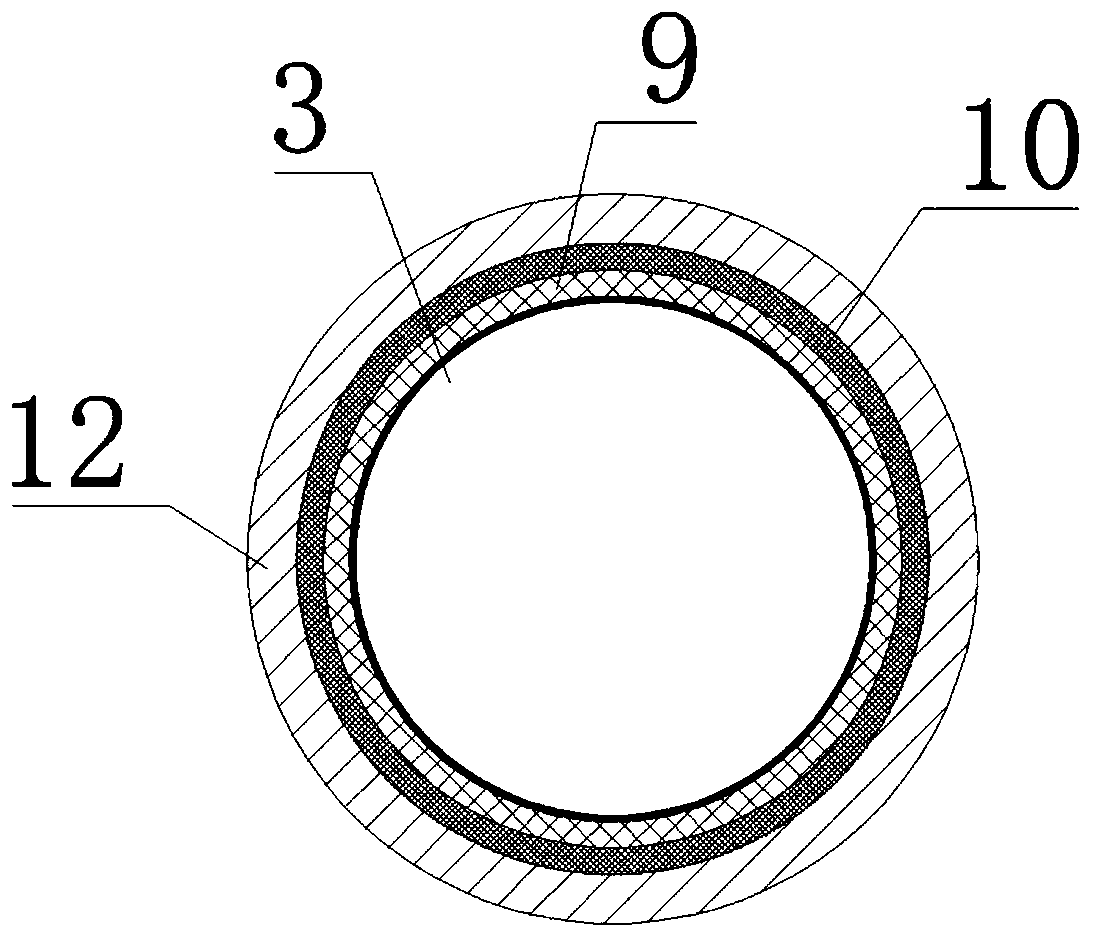

[0028] Such as figure 1 and figure 2 A natural dry casing production device shown includes a frame 1, on which a multi-layer casing support frame 2 is sequentially arranged from top to bottom, and the multi-layer casing support frames 2 are arranged in parallel and horizontally, and each layer of casing supports The frame 2 includes a plurality of casing support strips arranged at intervals. The casing support strip is an inflatable tube 3. The inflatable tube 3 is a soft material made of food-grade fiber material that has certain toughness and can expand or retract due to changes in internal air pressure. Inflatable tube, the two ends of the inflatable tube 3 are hung on the frame 1 through the elastic hook 6, the elastic hook 6 is a metal elastic hook, which has good toughness and elasticity, thereby playing the role of tensioning and preventing the inflatable tube 3 from sagging The adjacent elastic hooks 6 are equally spaced apart by the limiting slots 8 provided on the ...

Embodiment 2

[0036] see Figure 4 and Figure 5 A natural dry casing production device, comprising a frame 1, on which a multi-layer casing support frame 2 is sequentially arranged from top to bottom, the multi-layer casing support frames 2 are arranged in parallel and horizontally, and each layer of casing support frame 2 It includes a plurality of casing support strips arranged at intervals, the casing support strip is an inflatable tube 3, and the inflatable tube 3 is a soft inflatable tube made of food-grade fiber material that has certain toughness and can expand or retract due to changes in internal air pressure , the two ends of the inflatable tube 3 are hung on the frame 1 through the elastic hook 6, the elastic hook 6 is a metal elastic hook, which has good toughness and elasticity, so as to play the role of tensioning and preventing the inflatable tube 3 from sagging, relatively The adjacent elastic hooks 6 are equally spaced apart by the limiting slots 8 provided on the frame 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com