Method for influencing the kinematic behavior of a vehicle

A vehicle and motion technology, applied in the field of rail vehicles, can solve the problems of inaccurate temperature rise and temperature drop, no prediction of critical temperature, and model that does not allow heat conduction, etc., to reduce the risk of insufficient response, withstand maintenance, and achieve work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

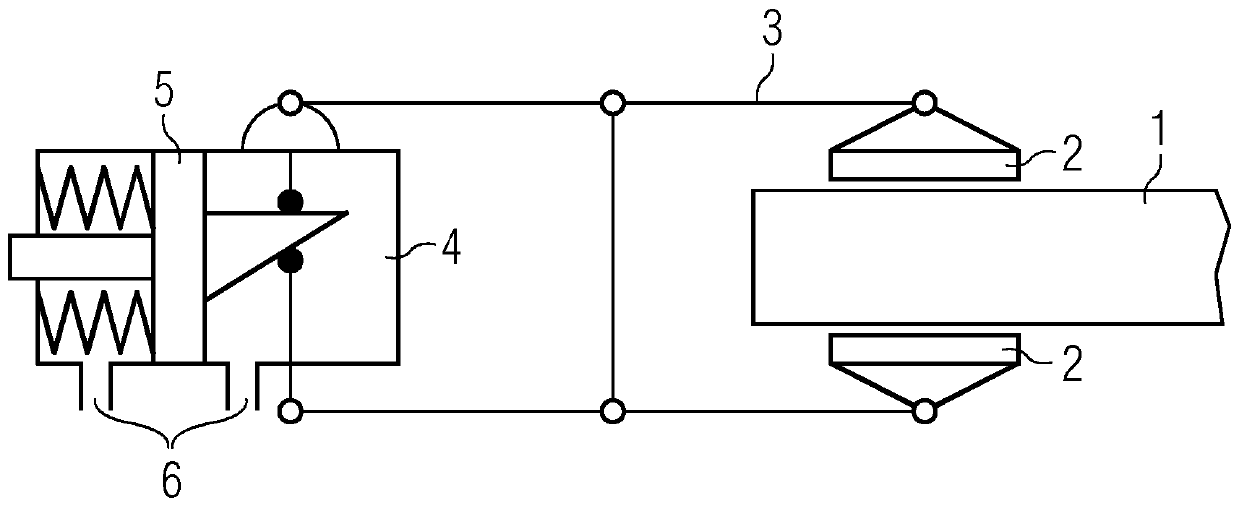

[0033] exist figure 1 , a schematically illustrated cross-section of a friction braking system of a rail vehicle showing a pneumatic disc brake.

[0034] The pneumatic disc brake comprises a first friction element 1 embodied as a brake disc mounted on a wheel set axle (not shown) of a rail vehicle, and a brake caliper. The brake caliper has a second friction element 2 comprising two brake pads. The brake caliper further comprises a brake cylinder 4 with a compressed air connection 6 , a piston 5 and a connecting rod 3 .

[0035] The piston 5 actuates the connecting rod 3 , whereby the brake pad arranged on the connecting rod 3 , ie the second friction element 2 , is pressed against the brake disc, ie the first friction element 1 . Compressed air from the rail vehicle's compressed air system (not shown) is applied to the piston 5 via a compressed air connection 6 to actuate the connecting rod 3 .

[0036] The compressed air system has components for open-loop control and clo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap