A method and system for monitoring rotor blades of a turbomachine using blade tip timing (BTT)

A technology of rotor blades and turbines, applied in gas turbine engine testing, using electromagnetic means, using wave/particle radiation, etc., can solve problems such as expensive and uncommon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The following description of the invention is intended only as a practical teaching of the invention. It will be apparent to those skilled in the art that many changes can be made to the described embodiments while still obtaining the beneficial results of the invention. It is also apparent that some of the intended benefits of the invention can still be achieved by selecting some of the features of the invention without changing others. Accordingly, those skilled in the art will recognize that modifications and adaptations to the present invention exist (and in some cases can even be desirable) and are a part of the present invention. Accordingly, the following description is provided to illustrate the principles of the invention and not to limit it.

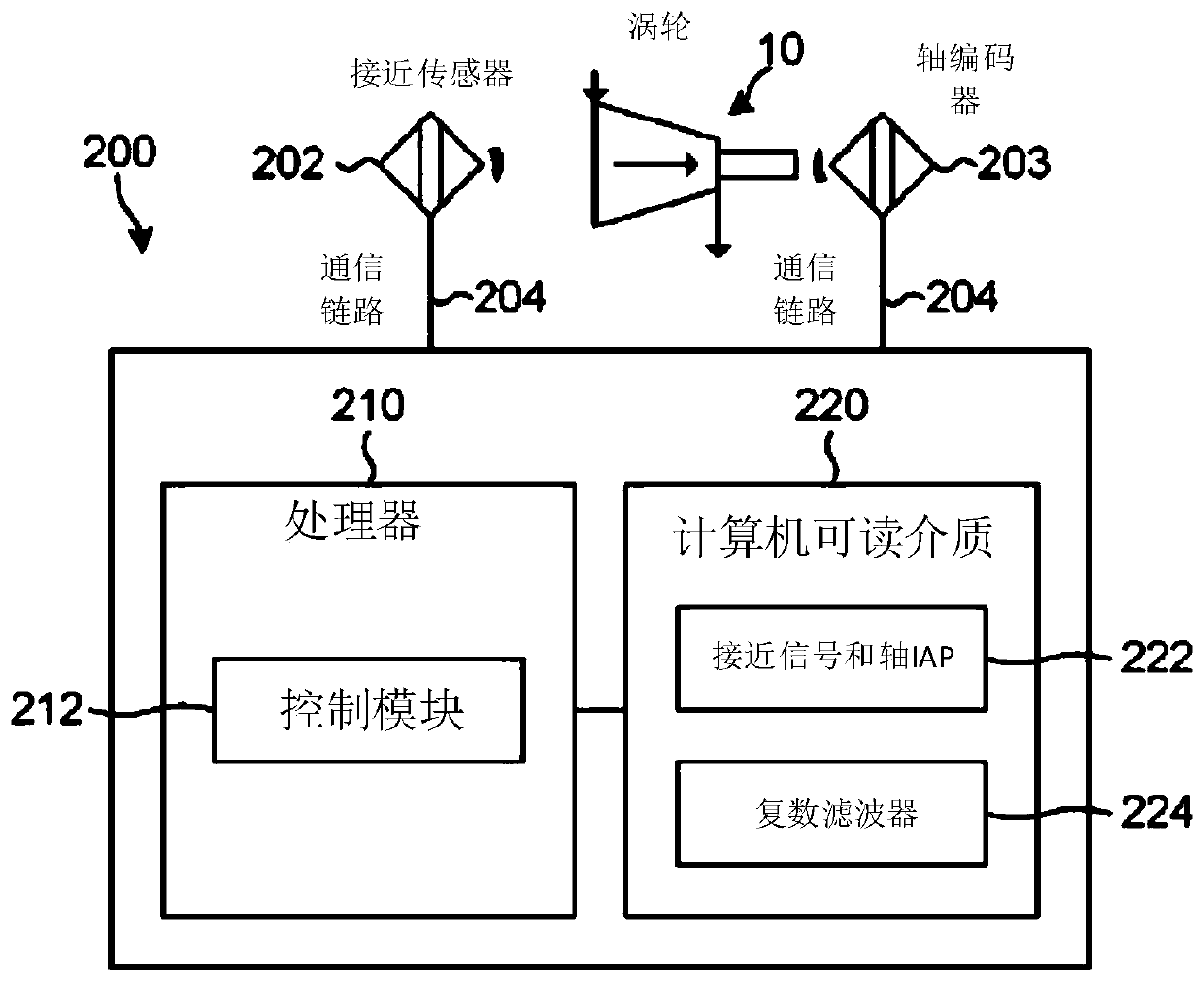

[0075] figure 2 Illustrated is a system 200 configured to determine or estimate tip deflection characteristics of moving rotor blades in a turbomachine. In this example, the turbine is turbine 10 . Turbine 10 may be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com