Automatic pancake machine

A pancake machine and automatic technology, which is applied in the direction of baking pancakes, baking, oil/fat baking, etc., can solve the problems of not being easy to clean, and the comb teeth are easy to store dirt, and achieve the effect of not being easy to store dirt, compact structure, and easy to clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

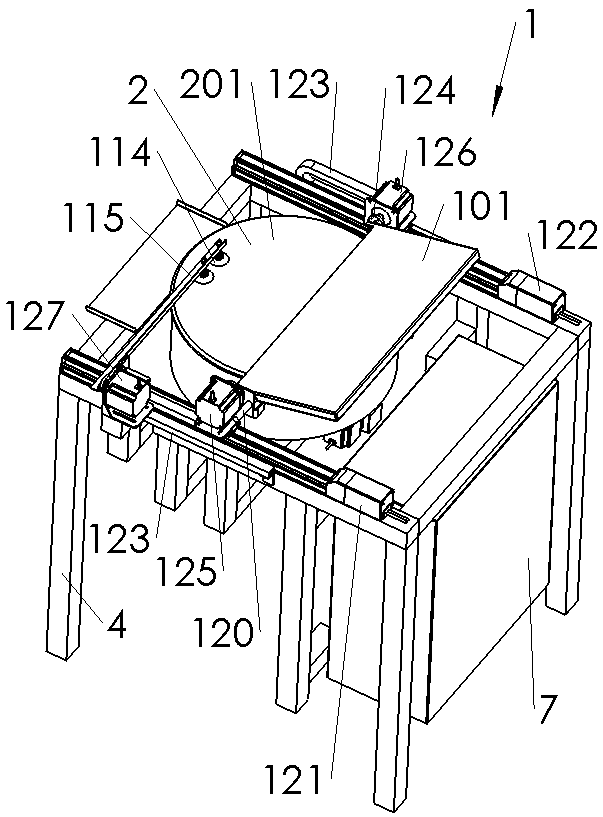

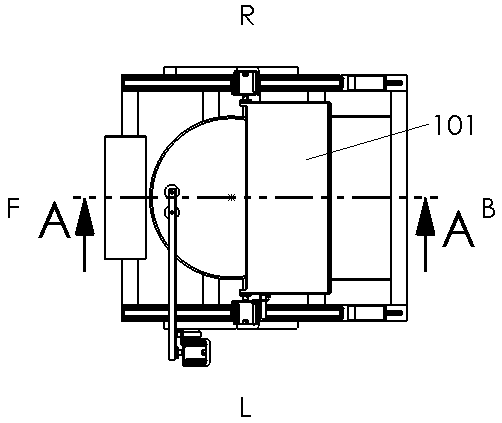

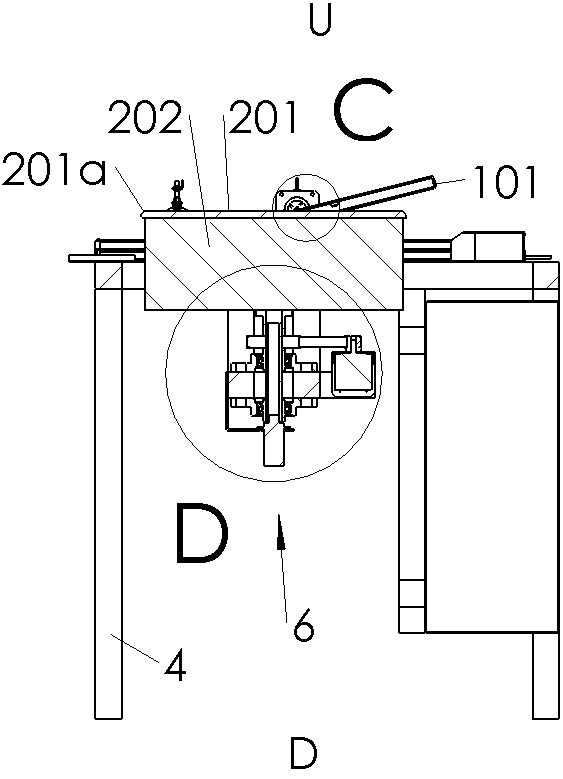

[0040] Such as figure 1 , 2 , As shown in 3, the pancake machine includes a folding device 1, a griddle 2, a griddle driving device 6, a frame 4, and an electric cabinet 7. In order to facilitate the description of the orientation of the structure, such as figure 2 and 3 , assuming that the surface 201 is placed horizontally, the places marked with F, B, L, R, U, and D are respectively defined as front, rear, left, right, up, and down.

[0041] The folding device 1 includes a shovel 101, a motor 125, a motor 126, two flanges 124, a sensor 120, a linear module 121, a linear module 122, two drag chains 123, at least one pressure head 114, a swing arm 115, and a motor 127 , (The linear module includes a linear guide rail, a slider that moves linearly on the guide rail, and a linear driver that drives the slider to move, and the linear driver includes a motor and a transmission structure).

[0042] The middle of the shovel 101 is the shovel plate 101a, the surface of the shov...

Embodiment 2

[0061] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is: the motor 126 is replaced by a bearing with seat 131, the bearing with seat is installed on the moving block of the linear module 122 through the connecting plate, and the right side 101c passes through the flange 124 and the bearing with seat The rotor of 131 is connected, and the rotor of motor 125 and the bearing with seat 131 is coaxial; the motor 125 drives the left side 101b to rotate, and the bearing with seat 131 supports the right side 101c and rotates drivenly, so that the shovel 101 is only driven by one side and the rotation control is simple. In this embodiment, the bearing with seat is used to support the rotation of the driven side of the shovel, and this structure for supporting the rotation of the driven side may not be required.

Embodiment 3

[0063] Such as Figure 11 , 12 As shown, the difference between the present embodiment and the first embodiment is that the left side 101b and the right side 101c are both folded edges that are folded 90 degrees toward the front of the shovel. The ribs 101e are still located on the back of the shovel. When the shovel 101 is shoveling pancakes, the output shaft center 101ab of the rotary drive part is in front of the shovel edge 101aa or on the same vertical plane with it, preferably the output shaft center 101ab of the rotary drive part is also above the shovel edge 101aa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com