Movable profile steel correction device and correction method of profile steel

A technology of correction device and section steel, which is applied in the field of correction equipment, can solve the problems of inconvenient correction, poor correction effect, difficulty in stabilizing the center of gravity section steel for stamping correction, etc., and achieve the effect of improved correction effect, convenient correction and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

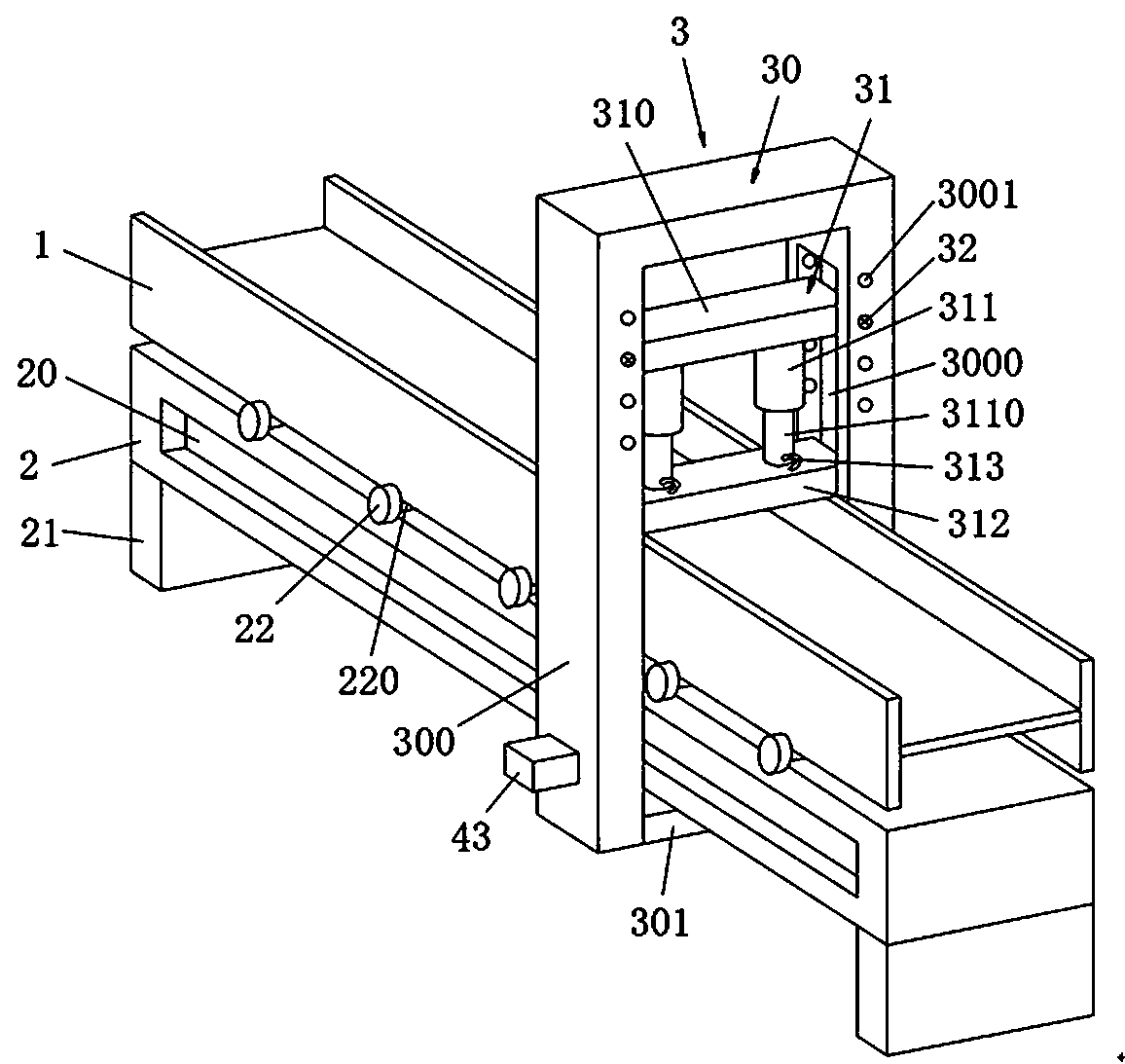

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

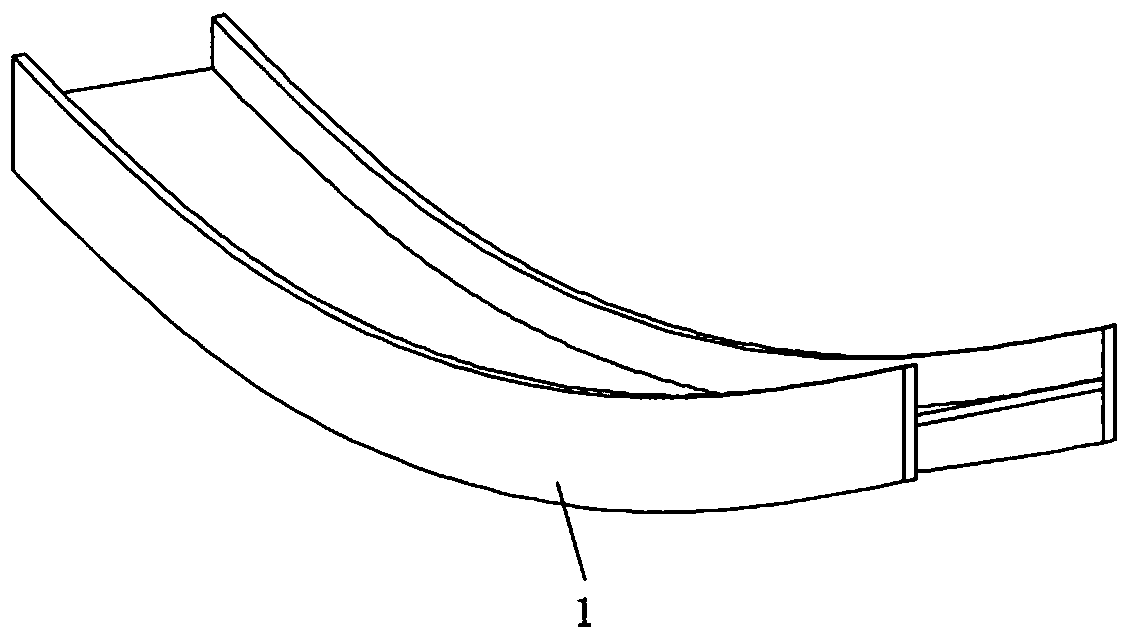

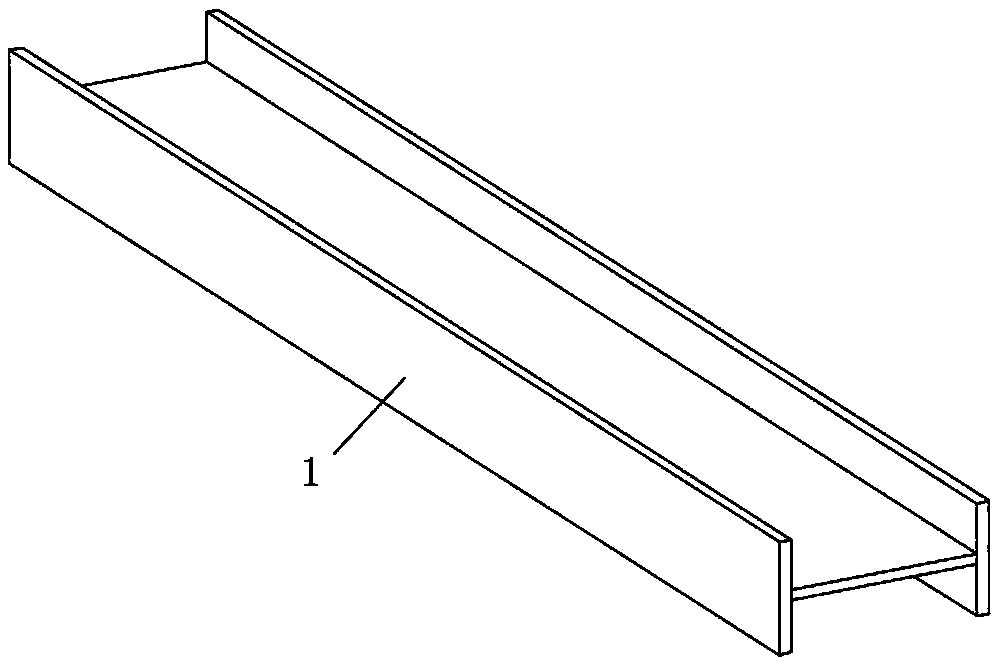

[0037] see Figure 1 to Figure 8 , a movable profile steel correction device, including a base 2 for placing profile steel 1 and at least one correction mechanism 3 arranged on the base 2; the correction mechanism 3 includes a support frame 30 and a Stamping device 31; the support frame 30 is slidably arranged on the base 2; the stamping device 31 includes a horizontal fixed rod 310, at least one hydraulic press 311 and a correction plate 312 fixed on the fixed rod 310; the fixed rod 310 is detachably fixed on the support frame 30; the hydraulic press 311 is longitudinally fixed on the lower end of the fixed rod 310; the correction plate 312 is arranged below the telescopic rod 3110 of the hydraulic press 311 and above the section steel 1, and stretched through the telescopic rod 3110 of the hydraulic press 311 The long drive correction plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com