Clamp for long shaft type irregular outer circle workpieces

An irregular, long-axis technology, applied in the direction of manufacturing tools, metal processing machinery parts, metal processing equipment, etc., can solve problems such as positioning and clamping difficulties, achieve high work efficiency, reduce production costs, and use simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

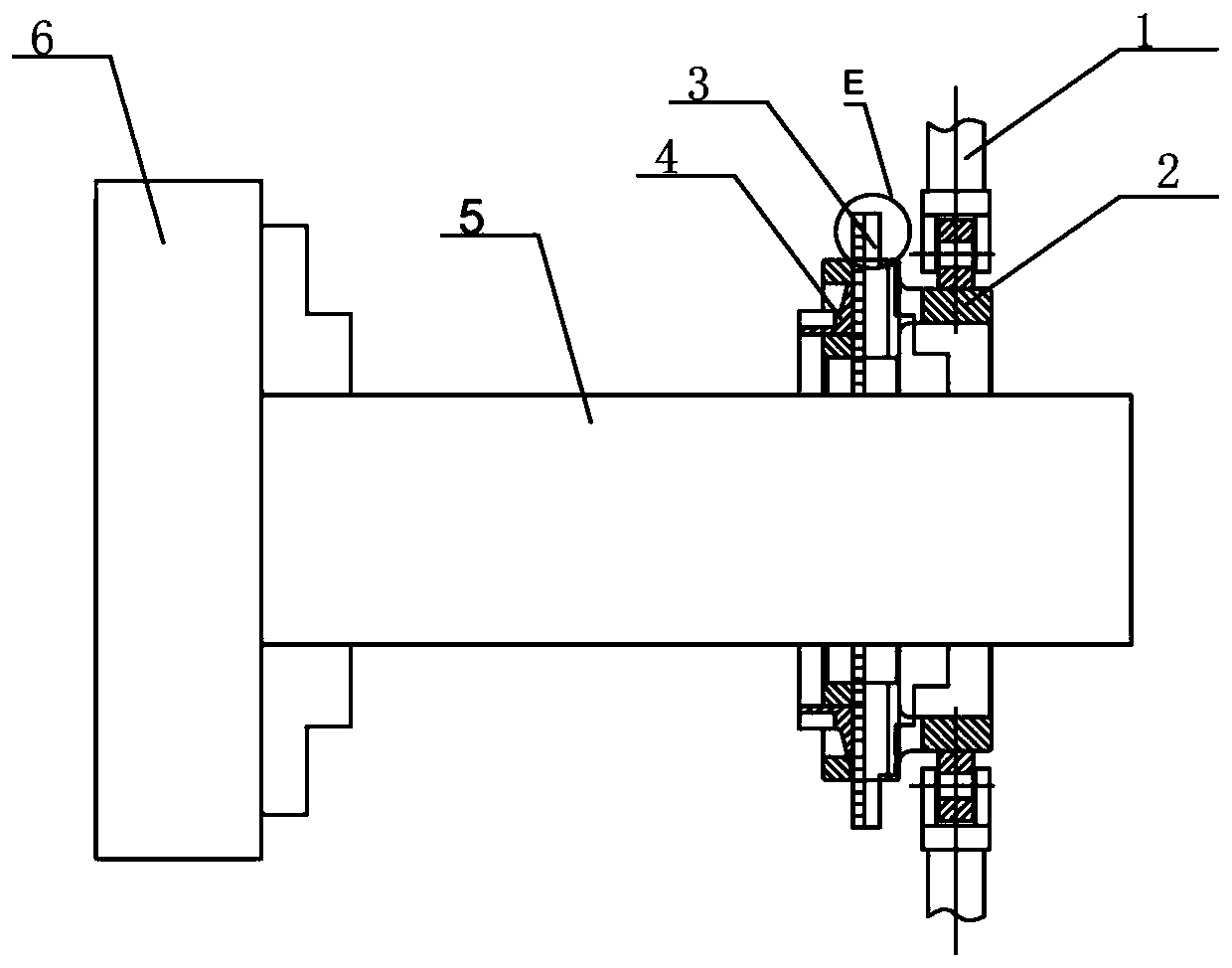

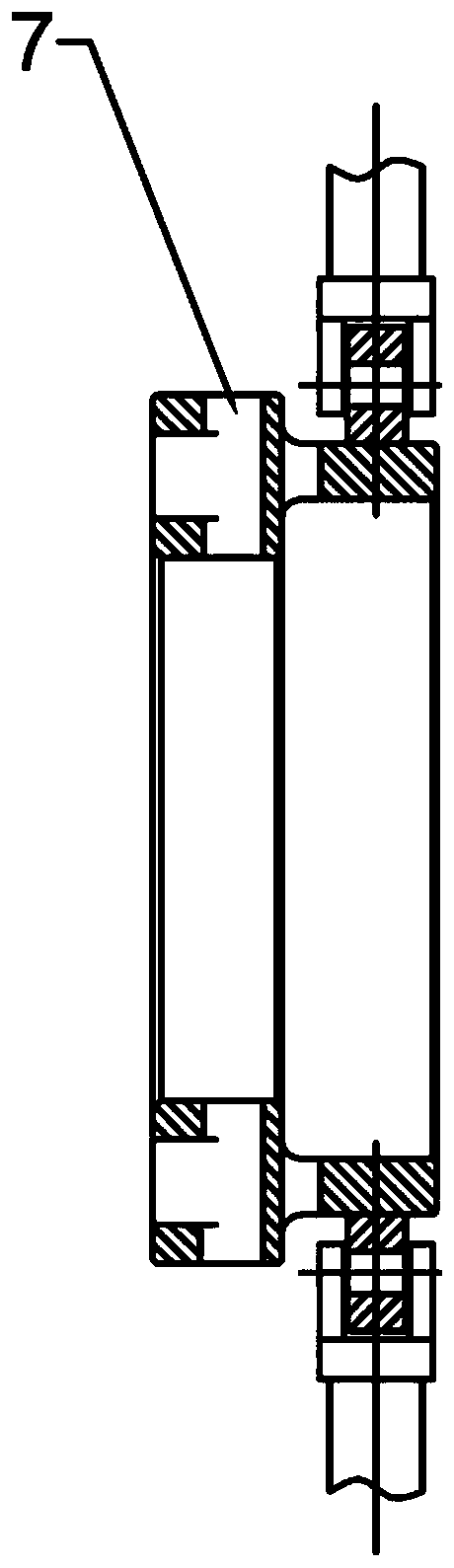

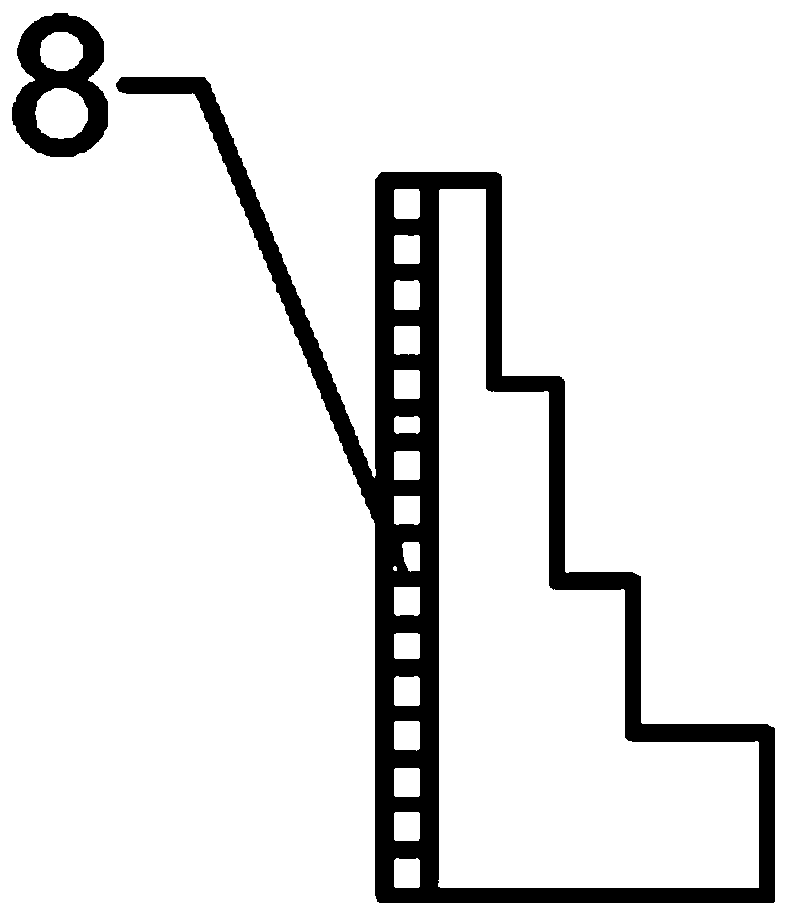

[0018] Embodiment 1: as figure 1 The long-axis irregular outer circle workpiece fixture shown in the figure is to provide a fixture that can hold irregular outer circle workpieces, from figure 1 It can be seen that a center frame 1 is provided directly in front of the lathe spindle 6 in the running direction, and a plurality of radially distributed rollers are arranged on the center frame 1. These rollers are combined to form a ring-shaped installation channel, and a positioning and locking device can be set in the installation channel. , the positioning and locking device includes a disc body 2, claws 3 and coil wire 4, from figure 2 It can be seen that the outer peripheral surface of the front side of the disc body 2 is set in the annular channel formed by the combination of the rollers of the center frame 1. The disc body 2 is a hollow annular body, and a through hole for fitting the workpiece 5 is opened along the axial direction of the disc body. 2 There is a ring groov...

Embodiment 2

[0021] Embodiment 2: This embodiment 2 is basically the same as embodiment 1. In order to ensure the locking effect of the claw 3, the difference is that, as Figure 7 As shown, the bottom surface of the claw 3 is tooth-shaped, and the claw 3 presses the workpiece 5 inwardly along the radial direction of the disc body 2 and locks it. Yes, when the pressure is constant, reducing the force-bearing area can increase the pressure and increase the friction between the claw 3 and the workpiece 5, and the workpiece 5 is screwed by the coil wire 4, the coil wire 4, the claw 3 and the disc After the body 2 clamps the workpiece 5, it rotates together with the workpiece 5 in the center frame to prevent the irregular outer circular workpiece 5 from turning over in the disc body 2, so that the jaws 3 have a better clamping effect.

[0022] Further, such as Figure 7 As shown, the top is provided with an end cover, which prevents the claw 3 from falling into the disc body 2, and is conveni...

Embodiment 3

[0023] Embodiment 3: Embodiment 3 is based on Embodiment 1 or Embodiment 2, in order to ensure the locking effect, such as Figure 6 As shown, teeth 10 are provided on the outer periphery of the rear side of the coil wire 4, and positioning holes 11 are provided on the disc body 2. Insert the rotating shaft of 12 into the positioning hole 11, use the teeth 10 on the wrench 12 to mesh with the teeth 10 on the wire 4, turn the wrench 12 counterclockwise, the teeth 10 on the wrench 12 rotate to drive the teeth on the wire 4 10 Turn clockwise, so that the pushing claw 3 of the deep groove thread on the coil 4 presses the workpiece 5 inwardly along the radial direction of the disc body 2 and locks it

[0024] It can be seen that the structure of the present invention is novel and unique. A disc body 2 is arranged on the existing center frame 1, and a plurality of claw through holes 7 are set on the disc body 2, and the claws 3 are set in the claw through holes 7. The movable claw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com