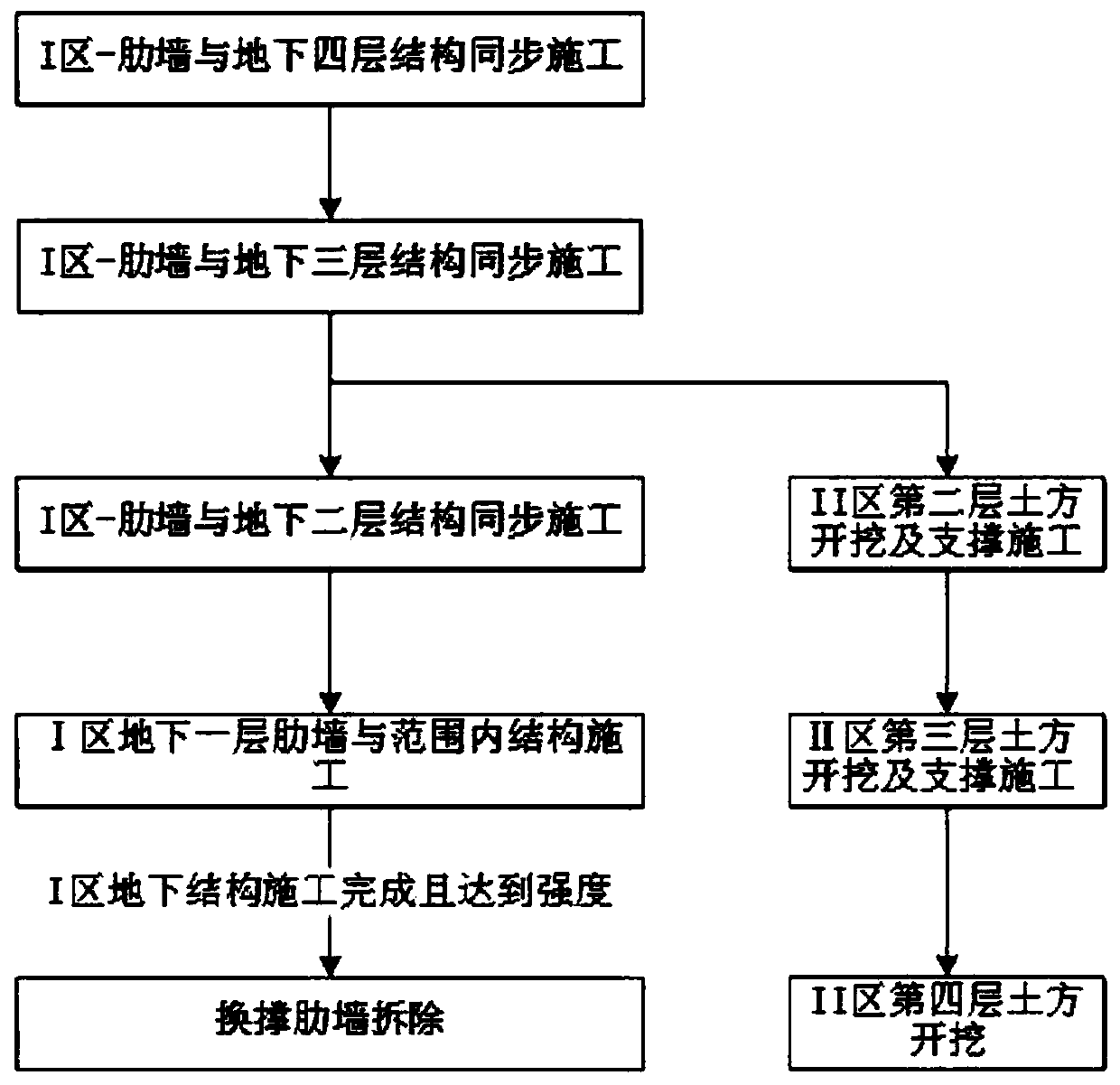

Deep-foundation-pit pit-dividing construction rib wall support replacement structure and construction method thereof

A construction method and deep foundation pit technology, which is applied in the direction of infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of large impact on the surrounding environment, large foundation pit deformation, long construction period, etc., and achieve stable and reliable force transmission, Replacing the support with stable force and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below for further understanding of the present invention.

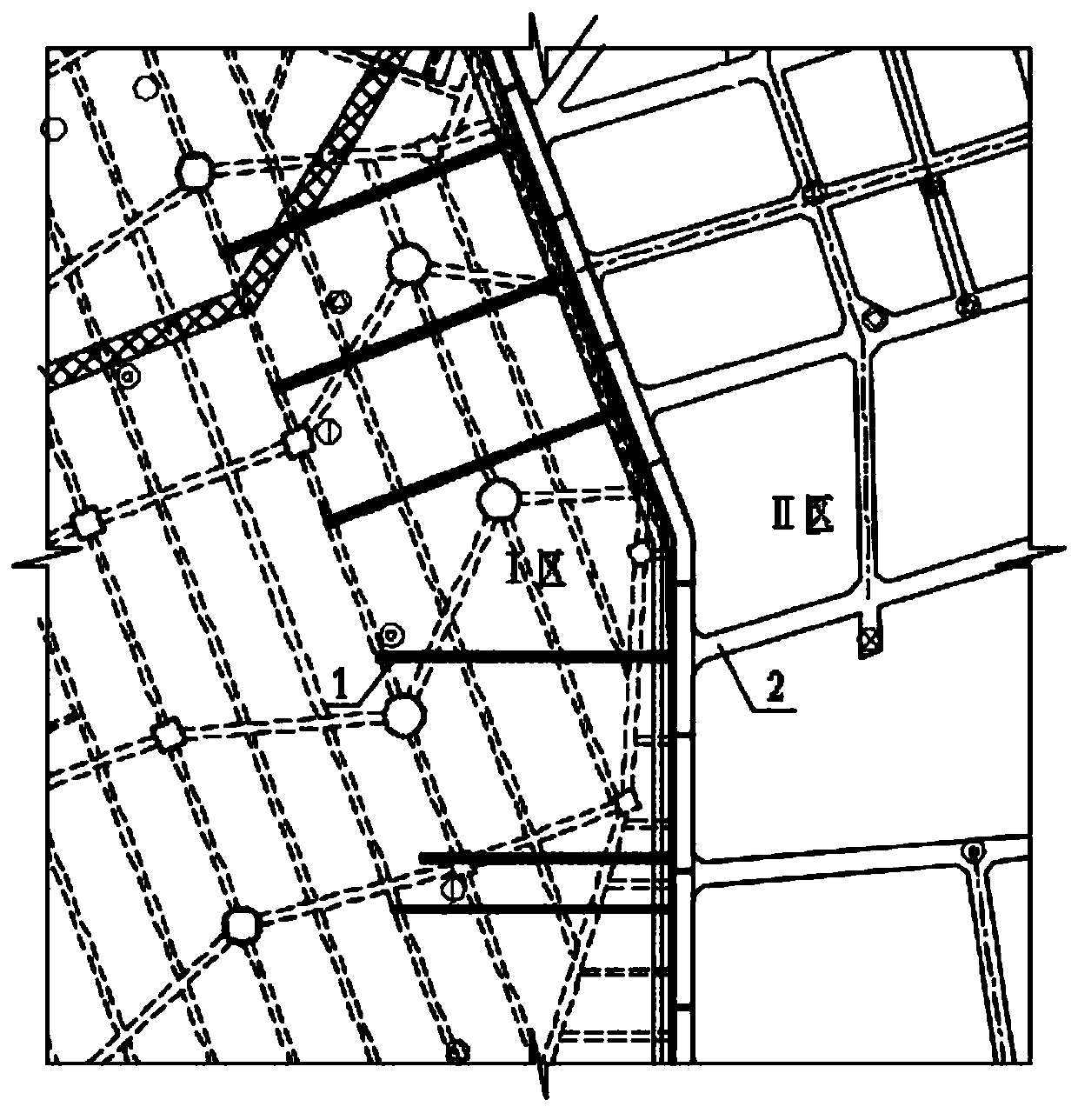

[0032] The 300mm thick reinforced concrete replacement shear wall 1 is set at the elevation from the basement floor to the basement roof. The horizontal interval and positioning distance of the replacement shear wall are determined according to the concrete support beams of the foundation pit in Area II (to face the foundation in Area II) Pit concrete support beam shall prevail), and the braced shear wall shall be constructed together with the basement structure, and shall be connected with the middle partition wall of the ground connection wall by planting bars. After the rib wall is used to replace the braces, after the construction of the middle floor of the basement in Area I (such as: the floor of B2 floor), the earthwork of the second floor adjacent to Area II can be excavated, and the earthwork in the adjacent area can be excavated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com