Tension-compression coupled yielding energy-absorbing grouting anchor rod for large deformation of surrounding rock and working method thereof

A grouting bolt, large deformation technology, applied in the direction of bolt installation, earthwork drilling, mining equipment, etc., can solve the problems of insufficient grouting, large deformation, bolt failure, etc., to eliminate stress concentration and improve stability. The effect of stability, tightness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

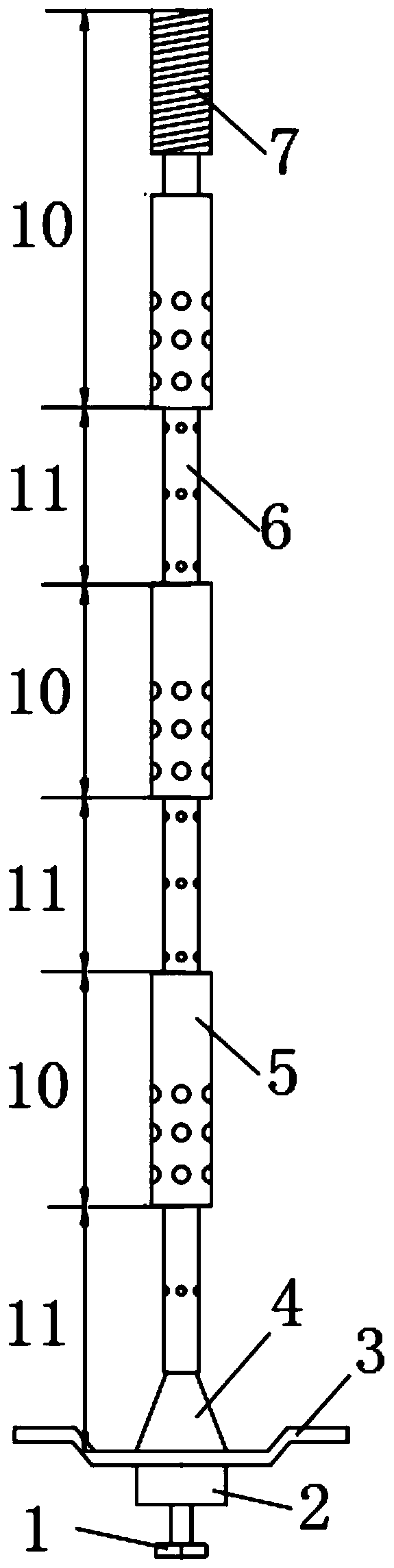

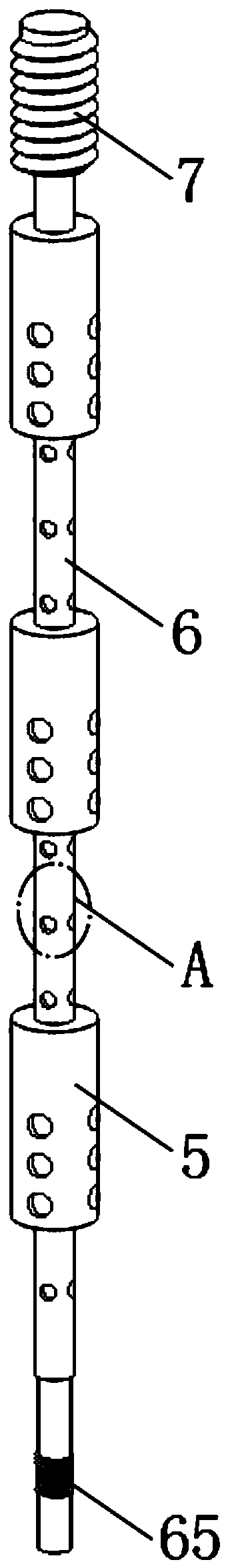

[0059] like Figure 1-8 , the tension-compression coupling yield-pressure energy-absorbing grouting bolt for large deformation of surrounding rock of the present invention comprises a hollow grouting bolt 6, a bolt locking device, a plurality of pressure-yielding grouting devices 5 and an energy-absorbing anchor Head 7, of which:

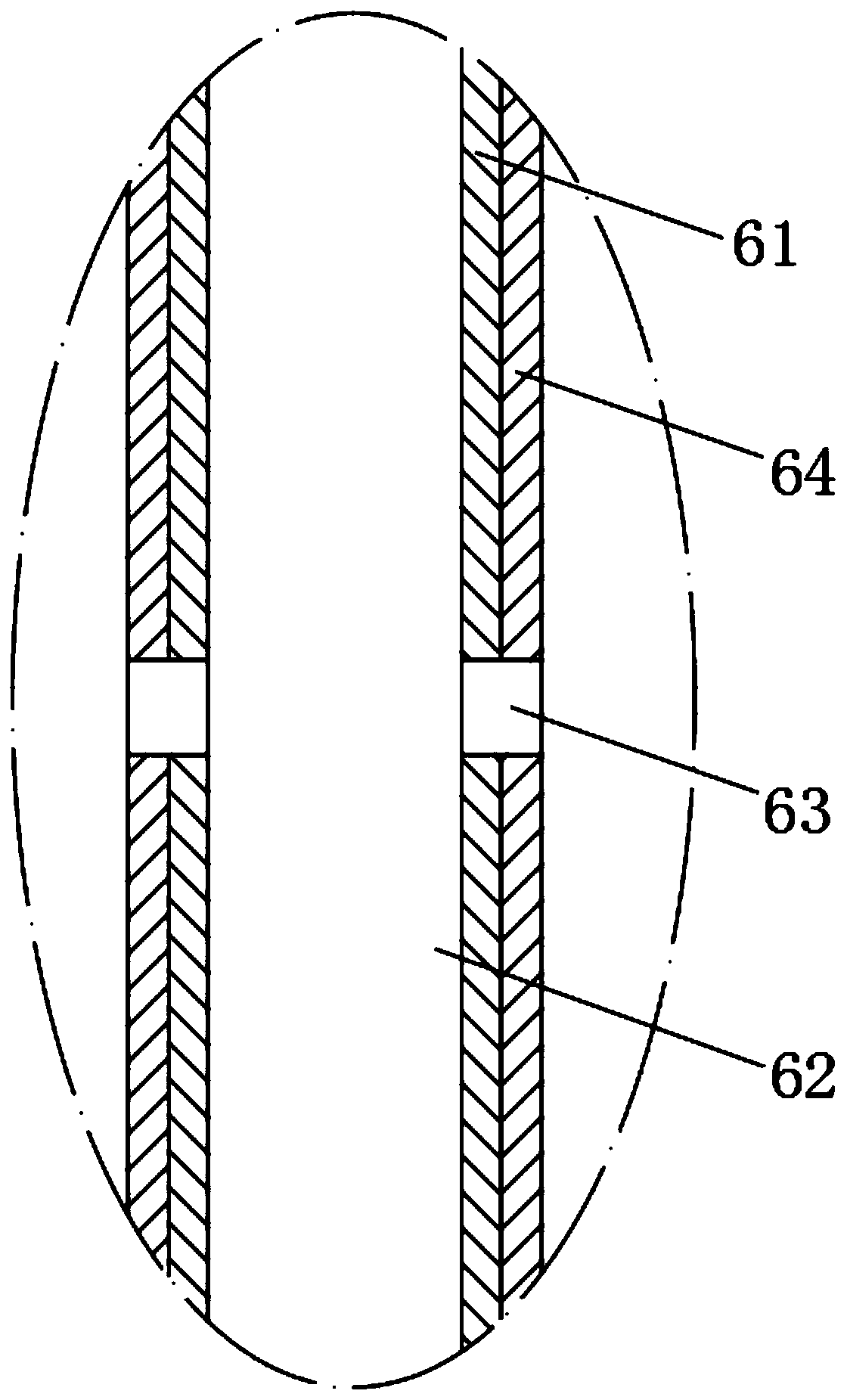

[0060] The hollow grouting anchor rod 6 includes a grout stopper 4, a hollow rod body 61 and a protective sleeve 64. The protective sleeve 64 is tightly sleeved on the rod body 61. The function of the protective sleeve 64 is to prevent The grouting slurry 8 flowing into the borehole is in contact with the rod body 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com