Anti-oil-leakage device used for electro-hydraulic servo valve

An electro-hydraulic servo valve and oil leakage prevention technology, applied in servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve problems such as affecting the surface quality of aluminum strip and foil processing, polluting the environment, wasting resources, etc., to prevent Oil spill problem, compact overall structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention can be explained in detail through the following examples, and the purpose of disclosing the present invention is to protect all technical improvements within the scope of the present invention.

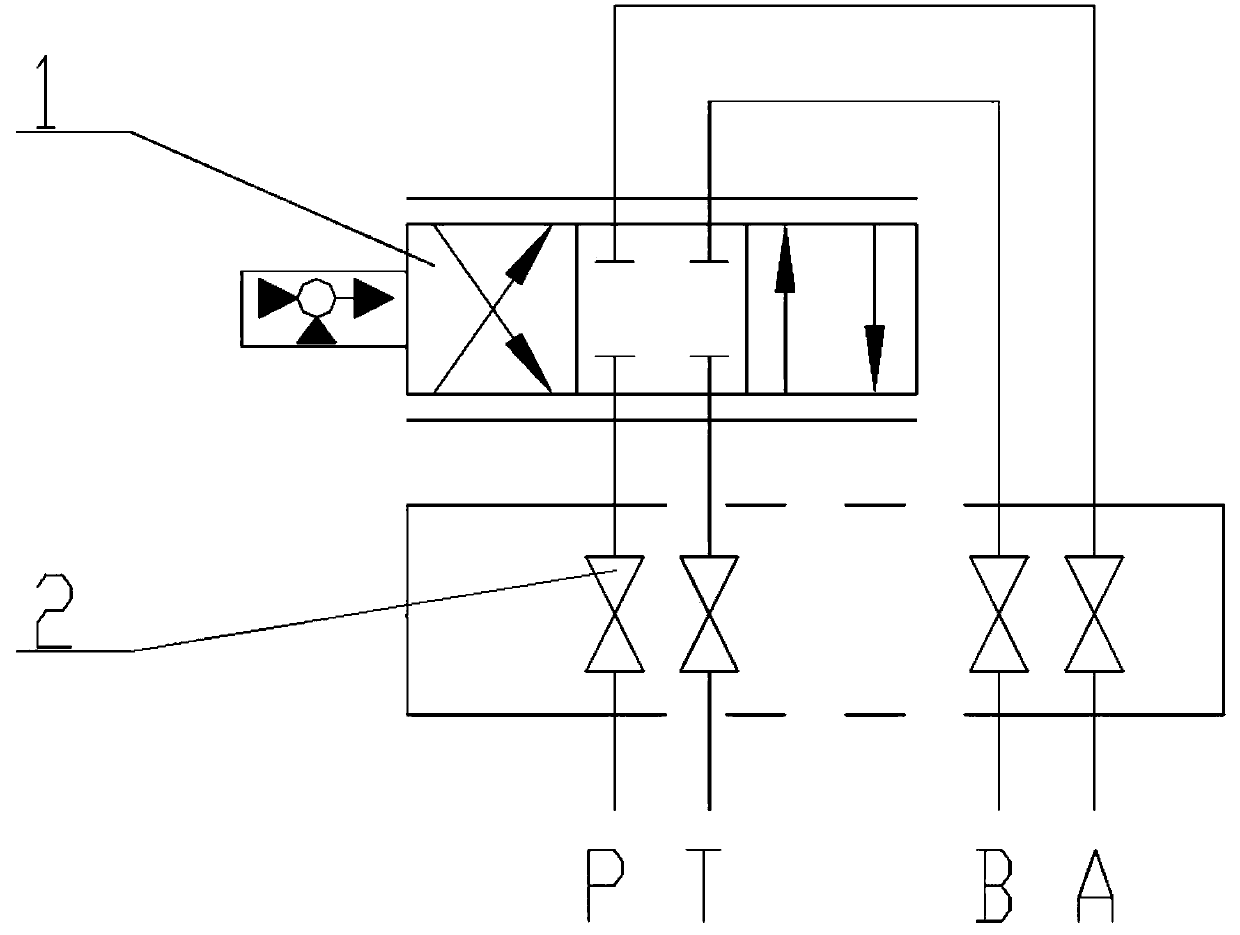

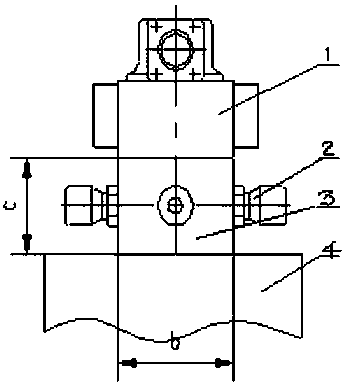

[0014] combine figure 1 and figure 2 The oil leakage prevention device for the electro-hydraulic servo valve includes the electro-hydraulic servo valve 1 and the system oil circuit block 4, and also includes a plurality of shut-off valves 2 and the bottom block 3 of the integrated shut-off valve. All oil inlets and outlets of 1 are respectively provided with shut-off valves 2, and several shut-off valves 2 are integrated on an integrated shut-off valve bottom block 3, and the electro-hydraulic servo valve 1 communicates with the system oil through the integrated shut-off valve bottom block 3. The circuit blocks 4 are superimposed and connected to realize oil circuit communication. When it is necessary to replace or close the malfunctioning electro-hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com