A kind of anti-clogging dust air volume control method and operation monitoring device of air preheater

An air preheater and operation monitoring technology, applied in combustion methods, heat exchange equipment, lighting and heating equipment, etc., can solve the problem of inability to adapt to boiler and auxiliary equipment systems, lack of sensitivity and accuracy, and real-time adjustment of ash air volume, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

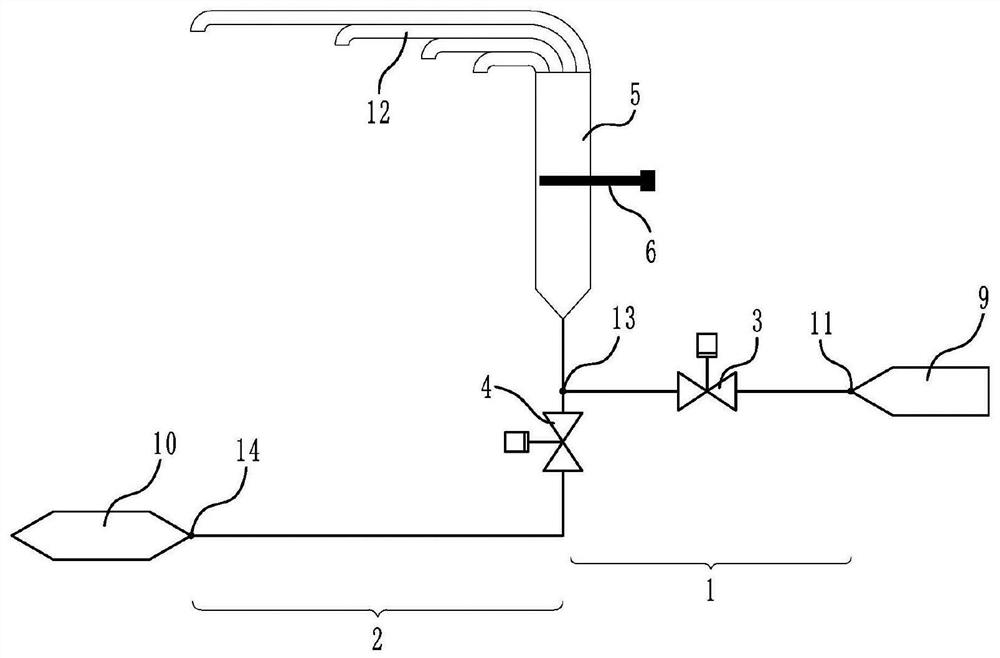

[0040] A method for controlling the anti-blocking dust air volume of an air preheater, which adjusts and controls the anti-blocking dust air volume through the variation of the amount of dust carried by the anti-blocking dust air. The change in the amount of dust carried by the anti-blocking dust air is used as the direct basis for the adjustment of the anti-blocking dust air volume, which realizes the real-time and evidence-based adjustment of the anti-blocking dust air volume and ensures the anti-blocking effect. In order to ensure the anti-blocking effect without wasting energy consumption, when increasing the anti-blocking dust air volume cannot carry more dust, the corresponding air volume is the target anti-blocking dust air volume.

[0041] As an air preheater anti-clogging dust operation monitoring device for realizing the above method, it includes a first sampling pipe, a second sampling pipe, a first sampling control valve, a second sampling control valve, a dust conc...

Embodiment 2

[0046] It is basically the same as that of Example 1, except that the anti-blocking dust air volume is gradually increasing from zero, and the amount of dust carried by the anti-blocking gray air is gradually increasing from zero. When the dust is carried out, the air volume is For the minimum operating air volume of anti-blocking gray wind, when the air volume continues to increase, the increase in the amount of dust carried out will transition from rapid increase to slow increase and finally stabilize. When the anti-blocking dust air volume is not less than the minimum operating air volume, in order to Taking into account both anti-blocking and energy-saving effects, when the anti-blocking gray air volume is increased or decreased by 1% to 10%, the measured change in the amount of dust carried by the anti-blocking gray air does not exceed 1% to 3%, and the current anti-blocking gray air volume is the target Anti-clogging gray air volume.

Embodiment 3

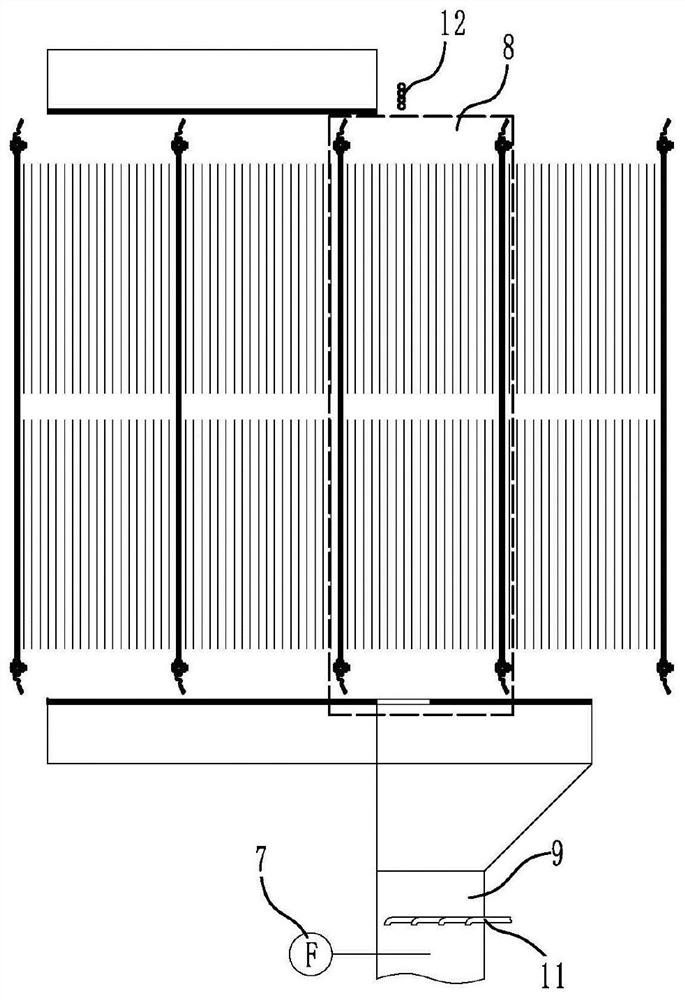

[0048] Basically the same as embodiment 2, the difference is: in order to improve the comprehensiveness of sampling, the first sampling end and the second sampling end all adopt the mixed sampling mode of 4 points, that is, both the first sampling end and the second sampling end There are 4 sampling ports. In practice, the number of sampling ports of the first sampling port and the second sampling port can also be respectively set to 5, 8 or 11 according to needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com