Method for evaluating environmental embrittlement resistance under simulated condition of R6 mooring chain

An evaluation method and mooring chain technology, which is applied in the field of environmental embrittlement performance evaluation of R6 mooring chain simulation conditions, can solve the problems of restricting the use of the hull and mooring chains, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose of the invention, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods;

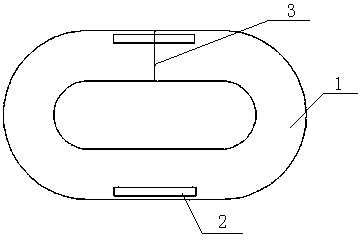

[0019] In the accompanying drawings: a method for evaluating the anti-environmental embrittlement performance of R6 grade mooring chains under simulated working conditions, which is characterized in that it includes the following steps: Step 1: Determine the sampling location; two sets of samples are taken from R6 grade mooring chains For the straight part of the ring, one group is taken from the back of the ring, and the other group is taken from the flash weld, and the sampling position should be as close to the surface as possible;

[0020] Step 2: prepare reference electrode and anode electrode;

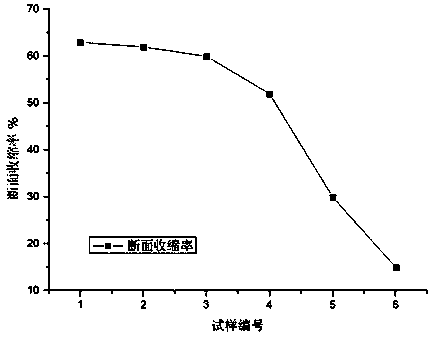

[0021] Step 3: Install a group of samples on the electro-hydraulic servo universal material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com