Testing device and method for testing durability of ultrathin wearing layer in tunnel

A technology for testing devices and wear layers, which is applied in the direction of testing wear resistance, measuring devices, and strength characteristics, and can solve problems such as damage, large differences in service life of ultra-thin wear layers, and cliff-like decline in anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

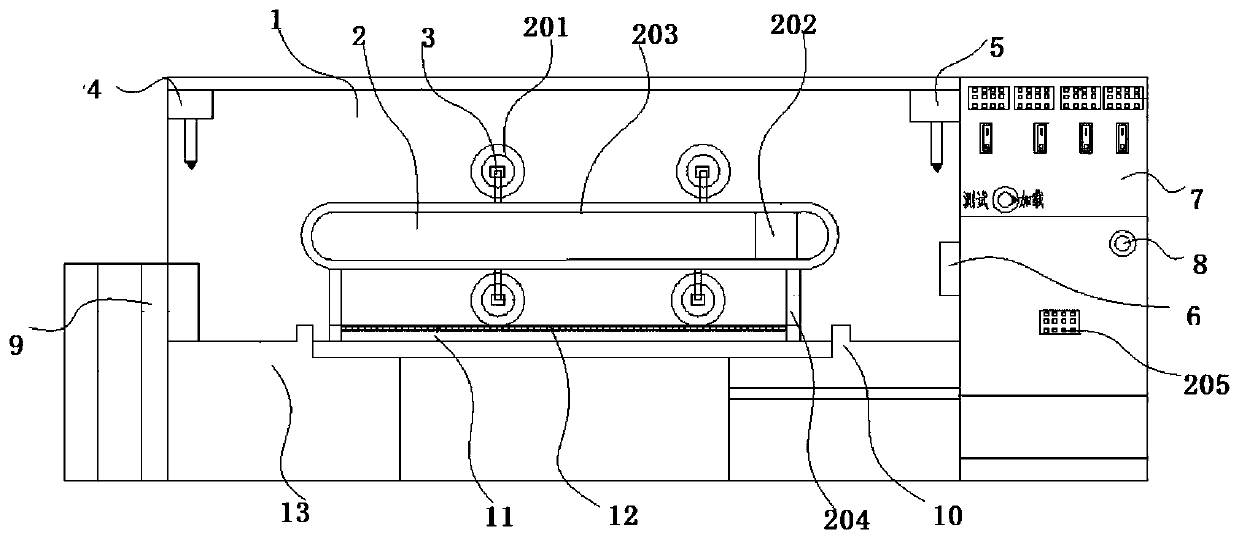

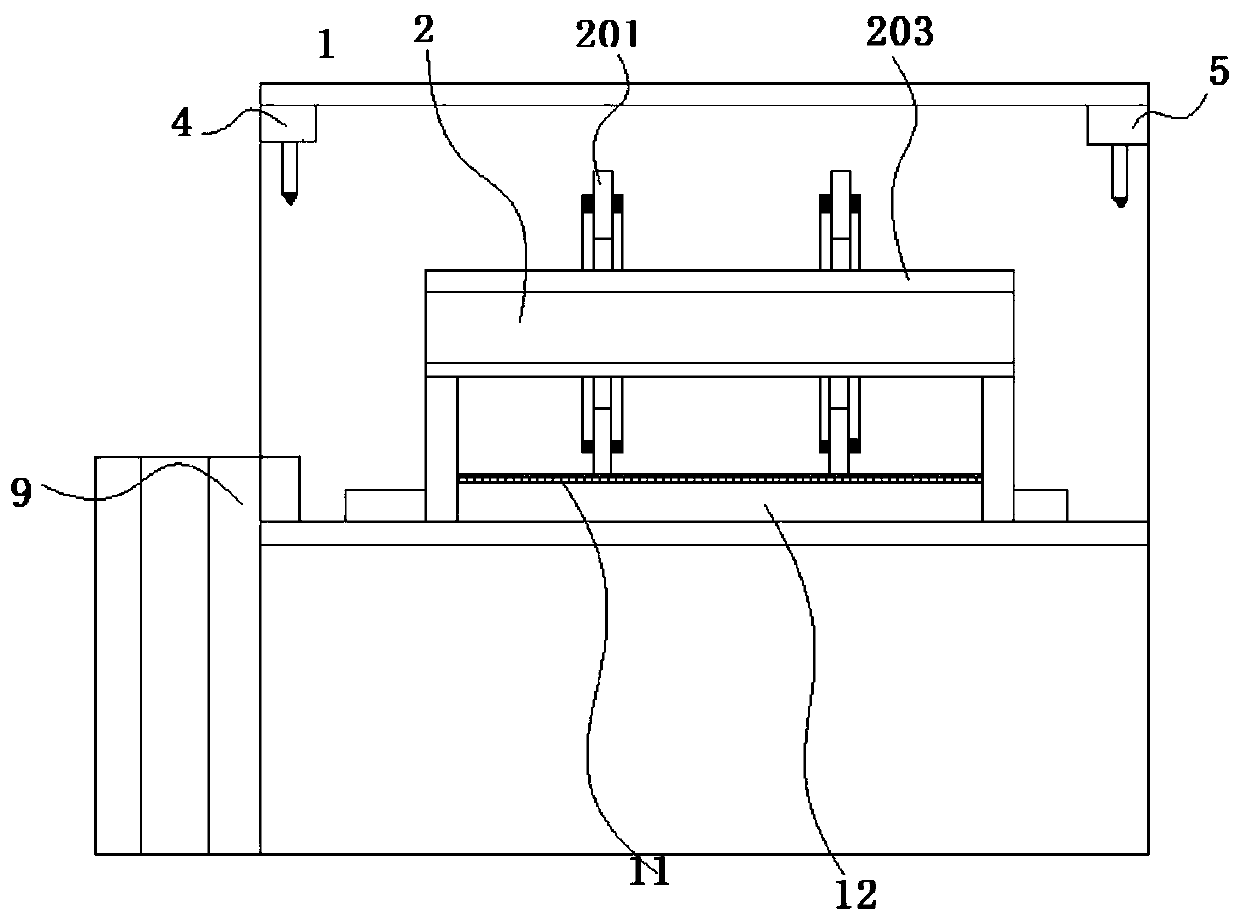

[0022] Such as Figure 1-2 As described above, the specific embodiment of the present invention is a test device for testing the durability of ultra-thin wear layers in tunnels, including a test box 1, a load unit 2, a test unit, and a control unit. The control unit is arranged in the test box 1 side, the bottom of one side of the test box 1 is also provided with an exhaust generator 13;

[0023] The middle part of the test box 1 is provided with a load unit 2, and the load unit 2 includes a rolling wheel 201, a tire pressure monitoring module 202, a crawler belt 203, a support rod 204 and a rolling times setter 205, and the middle part of the test box 1 It is a workbench 11, an ultra-thin wear layer test piece 12 is placed on the workbench 11, a support rod 204 is installed above the workbench 11, a crawler belt 203 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com