FPC gold finger surface defect detection system and method based on AOI technology

A defect detection and gold finger technology, which is applied in the field of FPC gold finger surface defect detection system, can solve the problem of high size specification and achieve the effect of improving detection efficiency and reducing detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below with reference to accompanying drawing and embodiment:

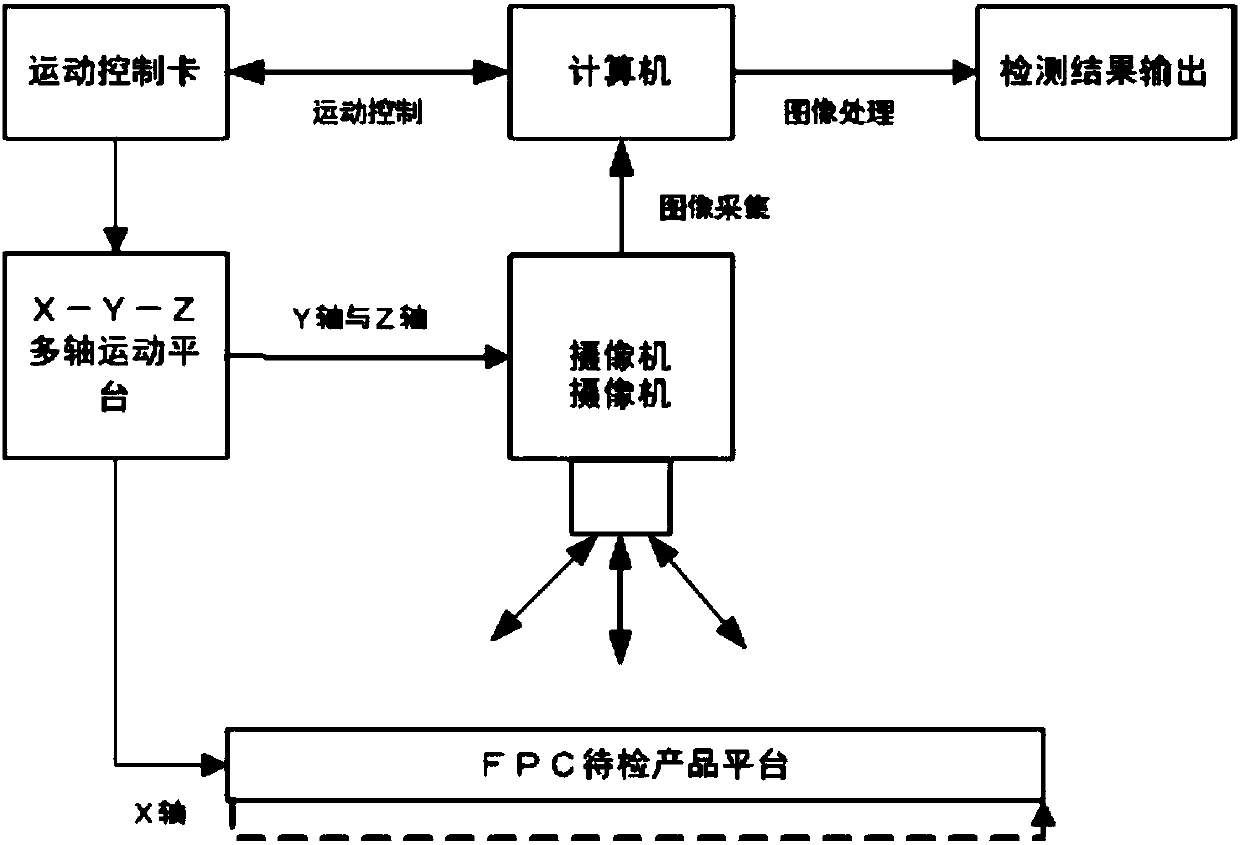

[0044] attached Figure 1-2 It can be seen that an FPC gold finger surface defect detection system based on AOI technology includes an X-Y-Z multi-axis motion platform and a camera. The X-Y-Z multi-axis motion platform includes a motor, a motor driver, a sliding module and a motion control card. The card performs movement control and positioning on the X-Y-Z multi-axis motion platform, the X-axis performs front-to-back movement control on the product platform to be inspected, and the Y-axis and Z-axis are responsible for the left-right and up-down movement control of the camera; the X-axis and Y-axis realize horizontal Direction movement, FPC surface detection, Z axis to realize the focal length adjustment of the camera; the camera performs digital image acquisition, and the camera is connected to the central processing unit through the RJ45 interface;

[0045] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com