Automatic measuring device for insulation of multi-core cable

An automatic measurement and multi-core cable technology, which is applied in the direction of testing circuit and testing dielectric strength, etc., can solve the problems of high labor intensity, easy missed detection, cumbersome operation, etc., and achieve the effect of saving labor in the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

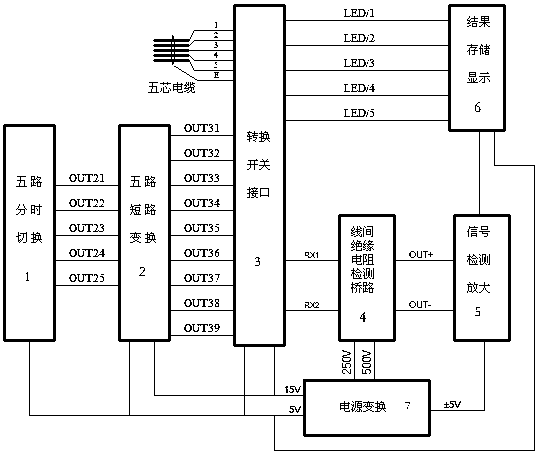

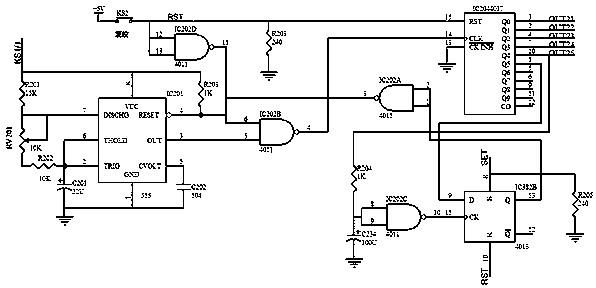

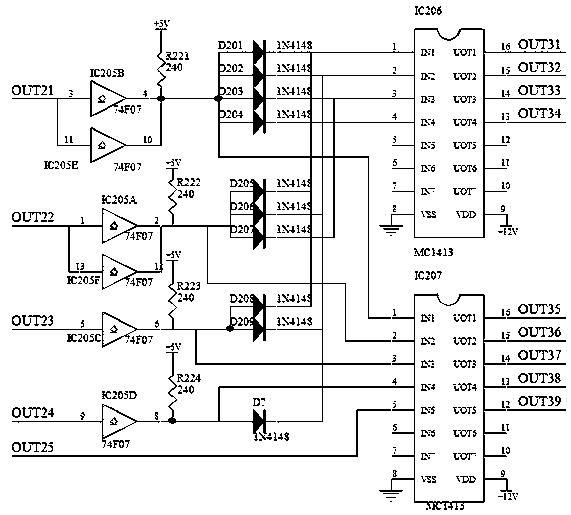

[0017] Now, the technical solutions in the embodiments of the present invention will be clearly and completely described in conjunction with the accompanying drawings. The accompanying drawings are simplified schematic diagrams and only schematically illustrate the basic structure of the present invention.

[0018] like figure 1 As shown, the present invention includes five-way time-sharing switching circuit 1, five-way short-circuit conversion circuit 2, transfer switch interface circuit 3 and inter-line insulation resistance detection bridge 4, including a signal outputting five-way time-sharing switching to five-way short circuit A five-way time-sharing switching circuit 1 at the input end of the conversion circuit 2; an output nine-way time-sharing short-circuit pulse signal is used to control the transfer switch interface circuit 3 for time-sharing switching. The five-way short-circuit conversion circuit 2, the five-way short-circuit conversion circuit The nine-way time-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com