A Lateral Radiation Hardened Power Device Structure

A power device and anti-radiation technology, which is applied in the direction of semiconductor devices, electric solid devices, semiconductor/solid device components, etc., can solve problems such as component performance damage, electronic equipment failure, etc., achieve anti-radiation reinforcement, solve anti-radiation Irradiation, the effect of simple and feasible process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

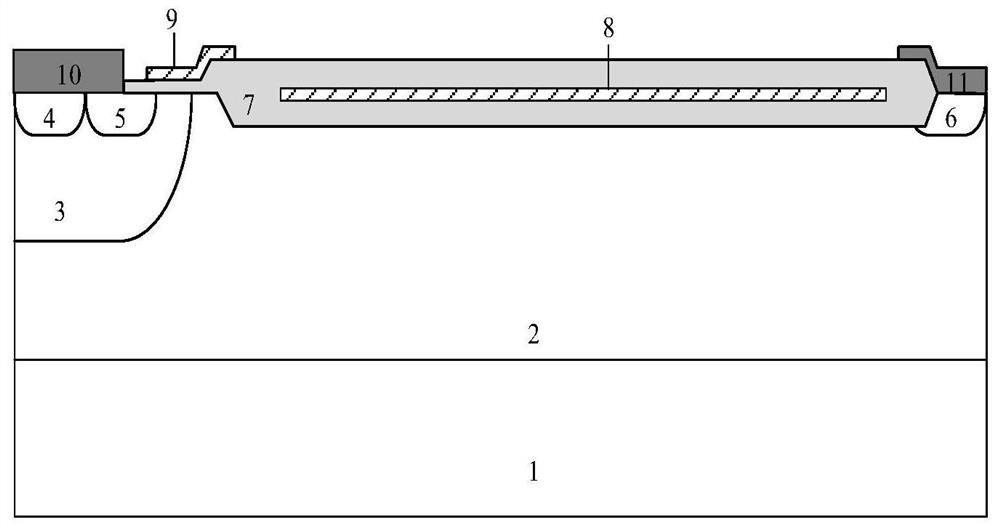

[0023] Such as figure 1 As shown, a lateral radiation-resistant power device structure includes a semiconductor substrate 1 of the second conductivity type, and a semiconductor drift region 2 of the first conductivity type located on the upper surface of the semiconductor substrate 1 of the second conductivity type is formed on the first The second conductivity type semiconductor well region 3 in the conductivity type semiconductor drift region 2, the second conductivity type semiconductor contact region 4 and the first conductivity type semiconductor contact region 5 located above the interior of the second conductivity type semiconductor well region 3 , the right side of the semiconductor contact region 4 of the second conductivity type is in contact with the semiconductor contact region 5 of the first conductivity type, and the semiconductor contact region 7 of the first conductivity type is located on the upper right side inside the drift region 2 of the semiconductor of th...

Embodiment 2

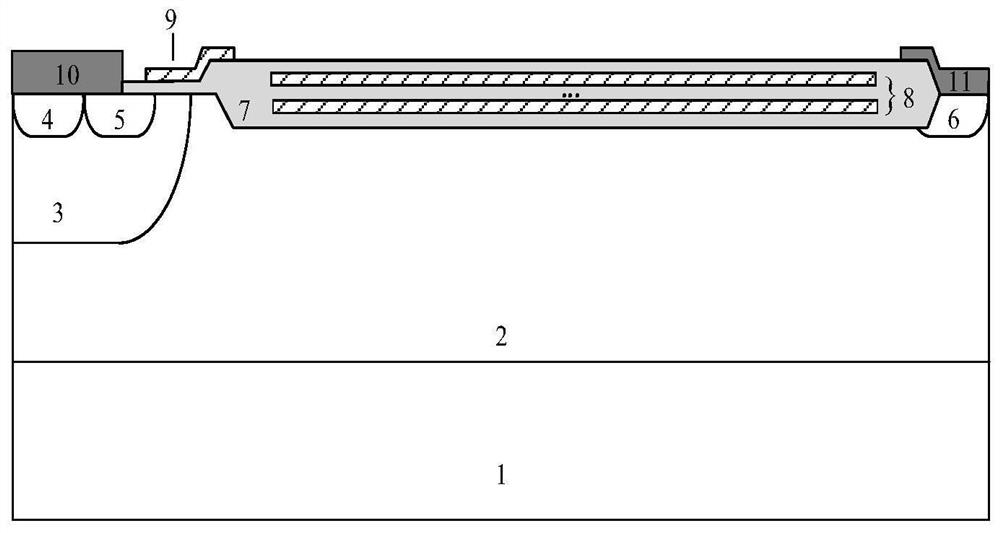

[0026] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that there are multiple layers of polysilicon strips 8 in the insulating layer 7 , each layer of polysilicon strips 8 are parallel to each other, and there is a longitudinal interval between adjacent polysilicon strips 8 . The vertical direction refers to the direction from the surface of the insulating layer 7 to the inside of the first conductivity type semiconductor drift region 2 .

[0027] This structure will further improve the radiation resistance of the device. There is no radiation-induced charge inside the parallel polysilicon strips. The impact of radiation on the oxide layer will be further reduced, and the modulation of the electric charge on the terminal electric field will be further reduced.

Embodiment 3

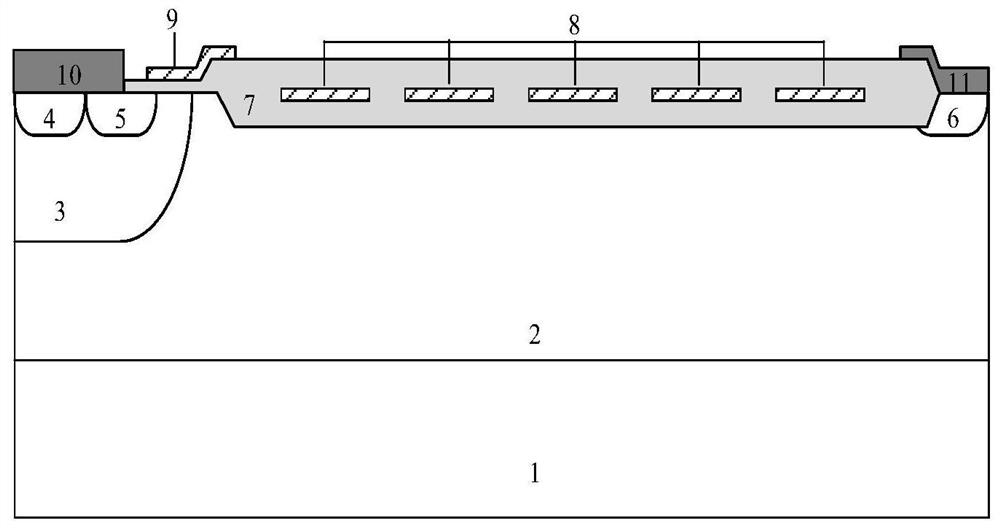

[0029] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the polysilicon strips 8 located in the insulating layer 7 are distributed intermittently in the lateral direction. This structure will further improve the anti-radiation capability of the terminal. A plurality of discontinuous polysilicon strips will modulate the terminal electric field in a non-radiative state and improve the withstand voltage of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com