A longitudinal vibrator array structure

A vibrator and vertical technology, applied in the field of acoustic arrays, can solve the problems of affecting performance and easy loss of vibration isolation effect of acoustic arrays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

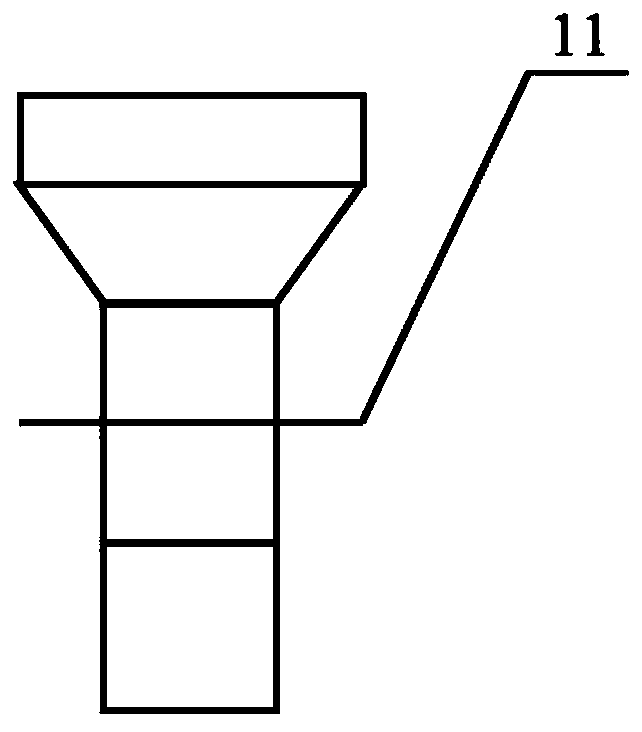

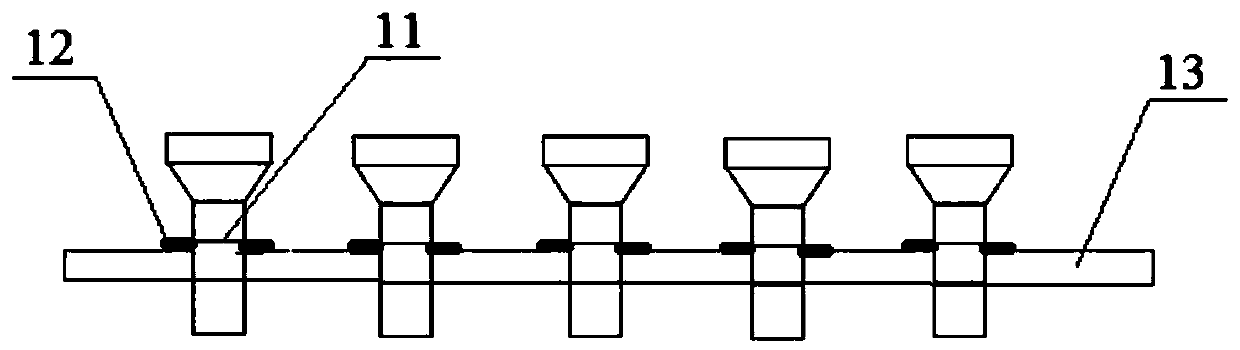

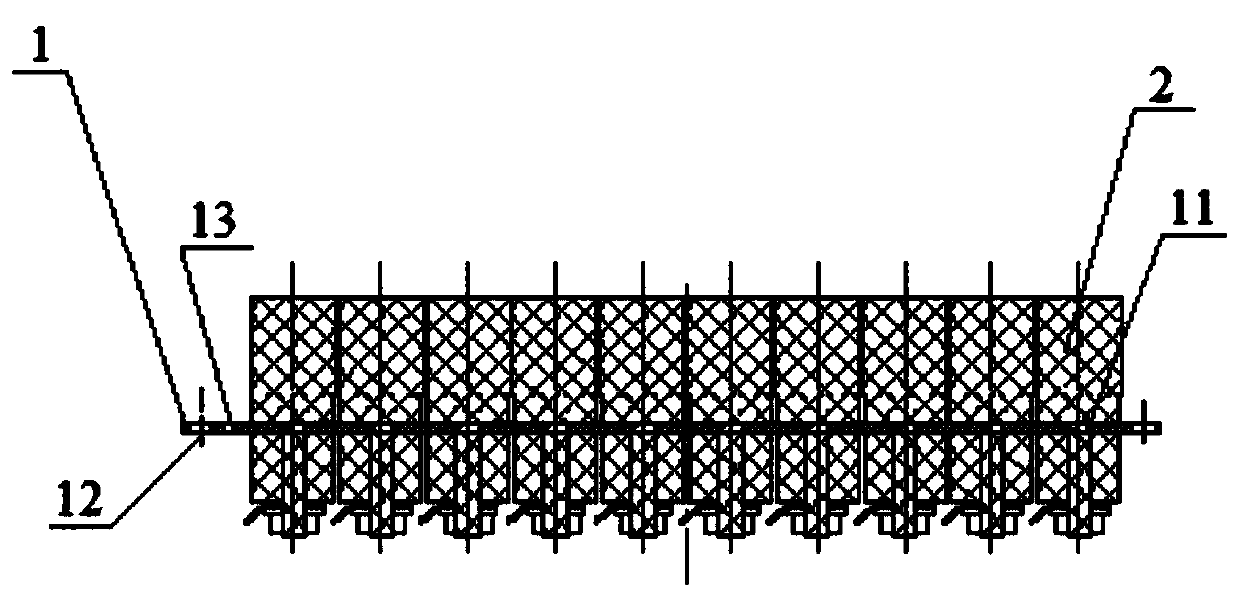

[0019] The invention provides an array structure of longitudinal oscillators, the structure of which is as follows image 3 shown. The array structure of longitudinal oscillators includes electrode sheets 1 and longitudinal oscillators 2 . see Figure 4 , is a schematic structural view of the electrode sheet 1 . The electrode sheet 1 is provided with several assembly holes 11, and the longitudinal vibrator 2 is installed on the electrode sheet 1 through the assembly holes 11 to form an acoustic array. The electrode sheet 1 is fixed to the substrate through the fixing hole 12; the electrode sheet 1 is provided with a lead-out hole 13 for leading out the positive lead-out line of the acoustic array.

[0020] read on Figure 4 , the plurality of assembly holes 11 are arranged in the word "one" on the electrode sheet 1, and the fixing holes 12 are respectively located at both ends of the electrode sheet 1.

[0021] The longitudinal vibrator 2 is assembled from ceramic and met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com