A fully automatic production system for SMD components dipped in silver at both ends

A production system and chip component technology, applied in the field of automation, can solve the problems of low work efficiency, waste of manpower and material resources, etc., and achieve the effect of high production efficiency, time saving, and precision will not change frequently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] combined with Figure 1-7 , the present invention is described in detail.

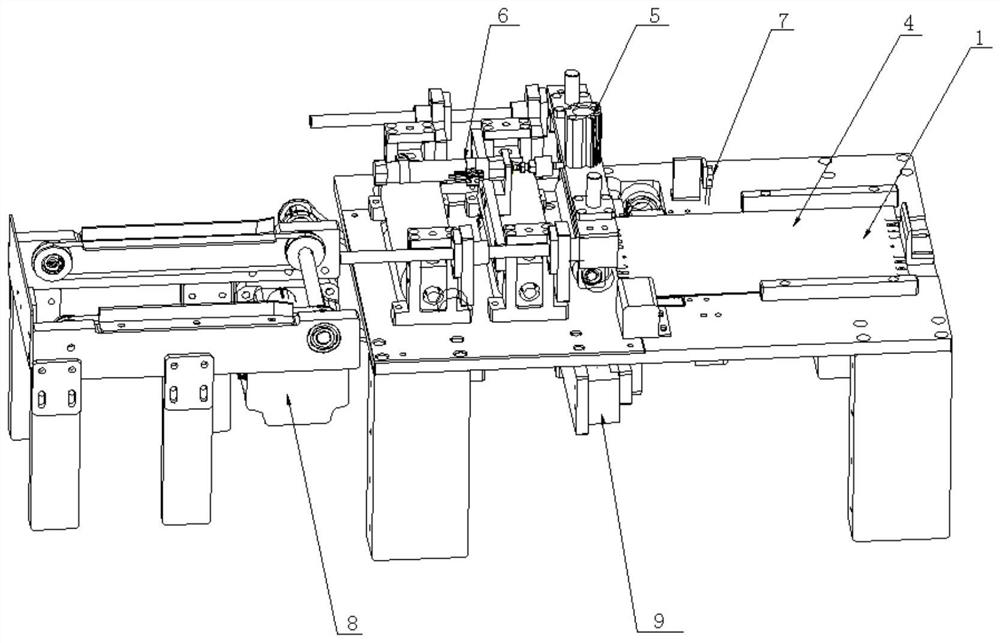

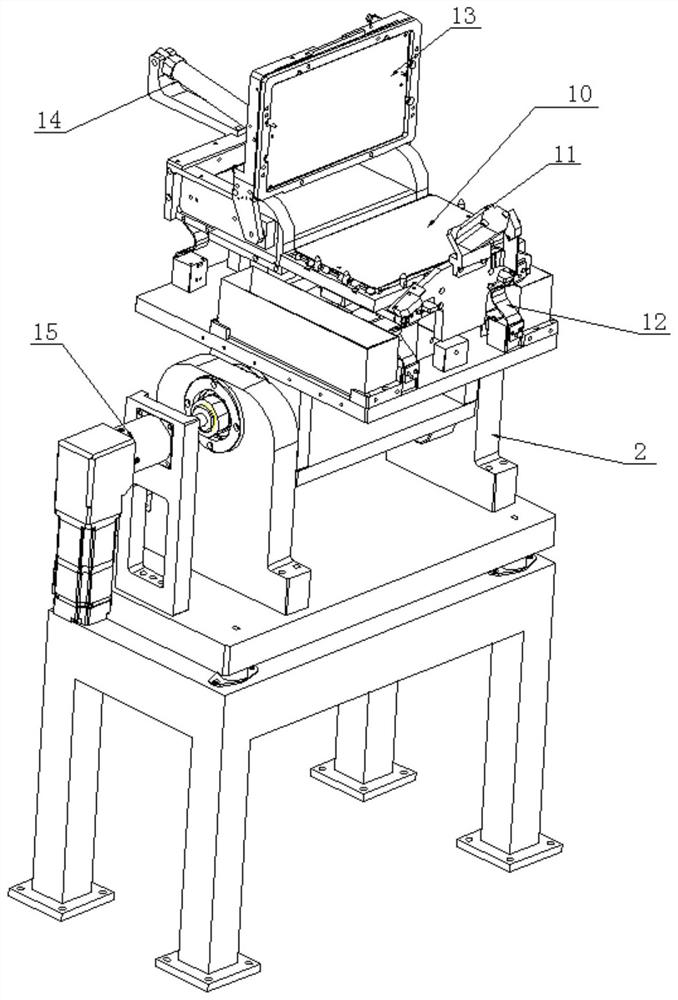

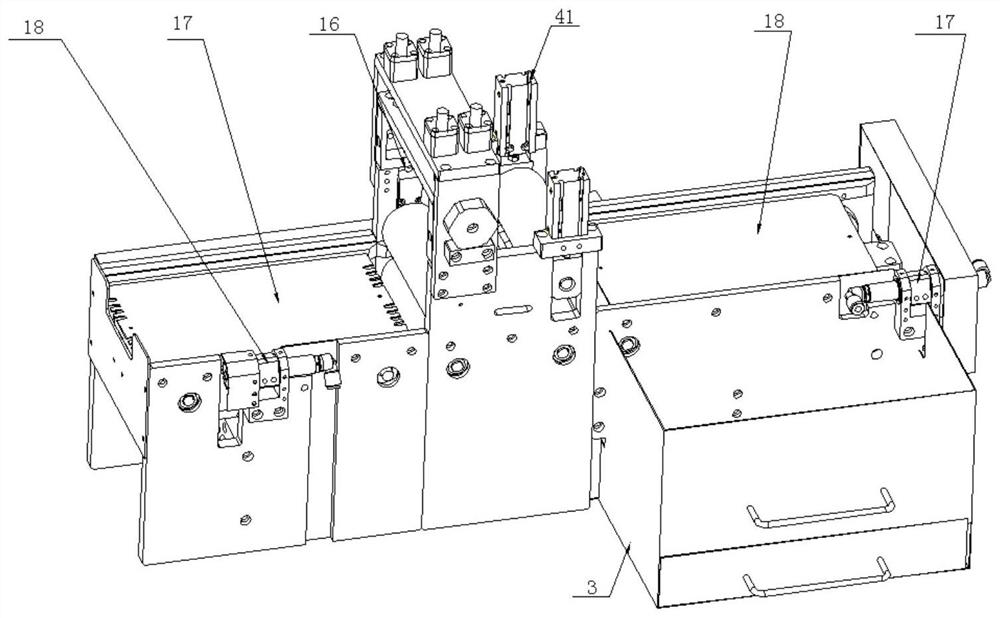

[0023] The present invention provides a full-automatic production system for dipping silver at both ends of patch components, including an automatic glue sticking and implanting leveling device, an automatic end capping device, an automatic drying device, an automatic glue sticking and surface changing device and an unloading device. material device, the automatic glue-applying implant leveling device comprises an automatic glue-applying device 1, an automatic implanting device 2 and an automatic leveling device 3, and the automatic glue-applying device 1 is provided with a plate-4 and a roller press-down cylinder successively 5. The roller pushes out the cylinder 6 and the stepping motor 8, a board sensor 7 is provided on one side of the board-4, a tape-cutting glue cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap