Municipal garden soil treatment device

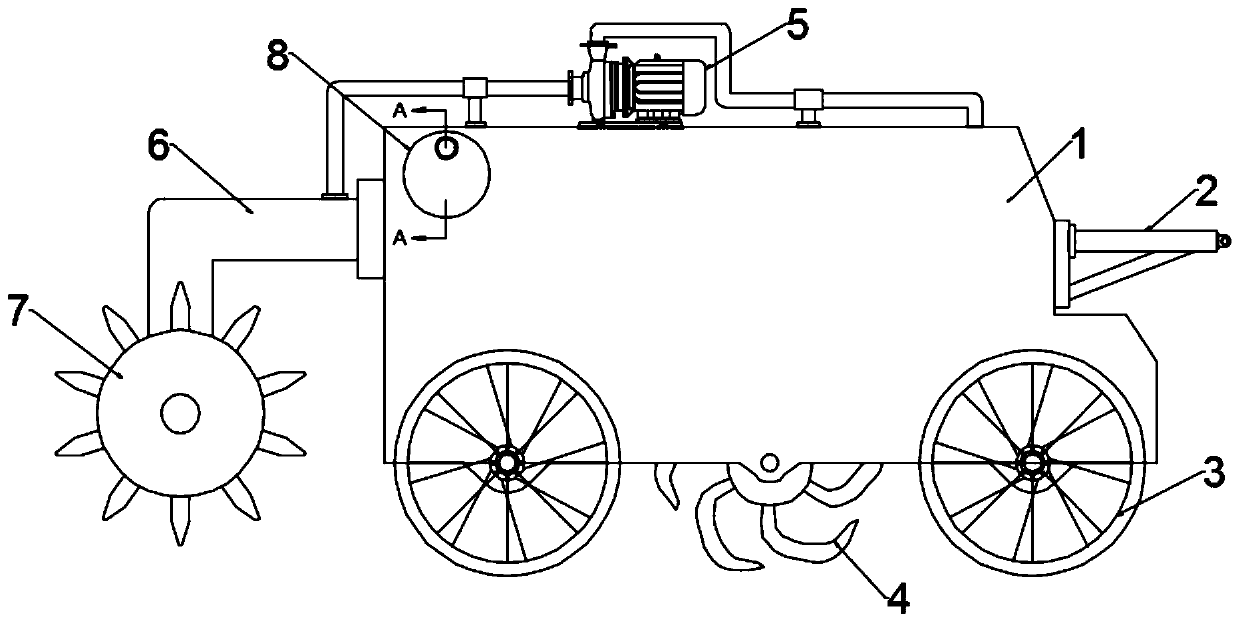

A garden and soil technology, applied in the restoration of polluted soil, shovels, plows, etc., can solve the problems of inability to meet rapid treatment, low treatment efficiency, etc., and achieve the effect of good treatment effect, novel design and high treatment efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

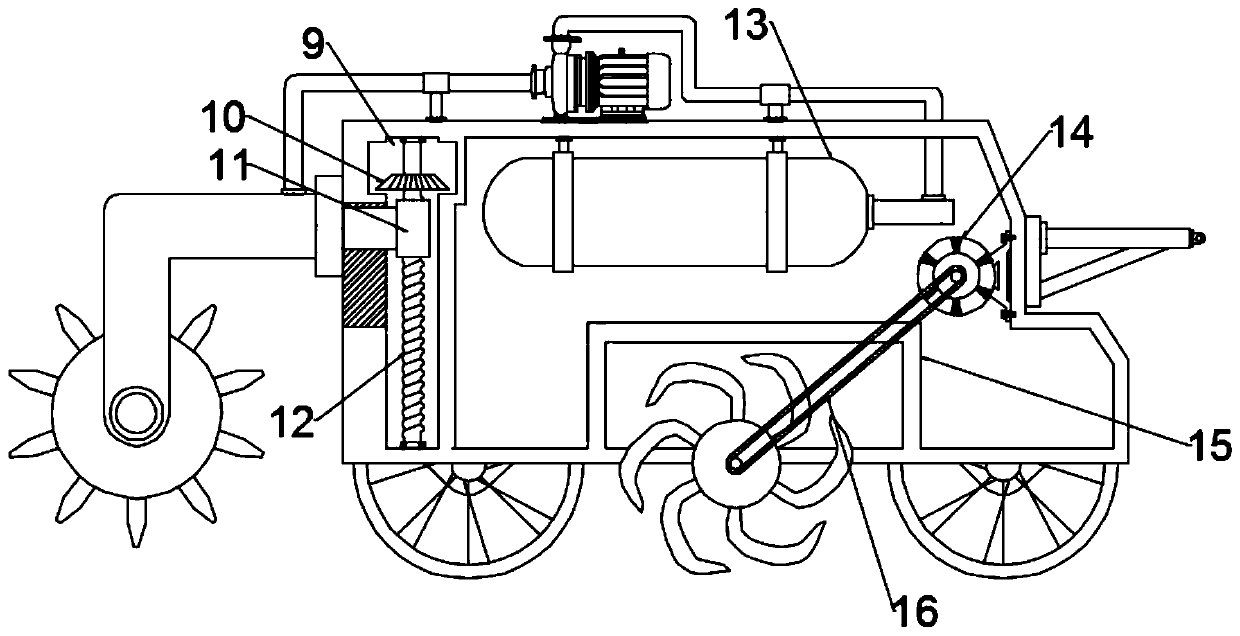

[0036] During soil treatment, it is necessary to treat soils of different depths according to different environmental requirements to improve the treatment effect. Therefore, in the specific implementation process of the present invention, another embodiment is proposed to improve the application. Specifically, It includes an adjustment component for adjusting the height of the bracket 6.

[0037] The adjustment component includes:

[0038] The adjustment cavity 9 is arranged at the inner end of the casing 1, and the side end is provided with a through slot penetrating the casing 1;

[0039] The threaded rod 12 is rotatably installed in the adjustment cavity 9, and a threaded sleeve 11 is threadedly connected to it. The threaded sleeve 11 is fixedly connected to the bracket 6 through a connecting block penetrating through the groove. The threaded rod 12 is rotated through a threaded sleeve The function of the barrel 11 and the connecting block drives the bracket 6 to adjust the up a...

Embodiment 3

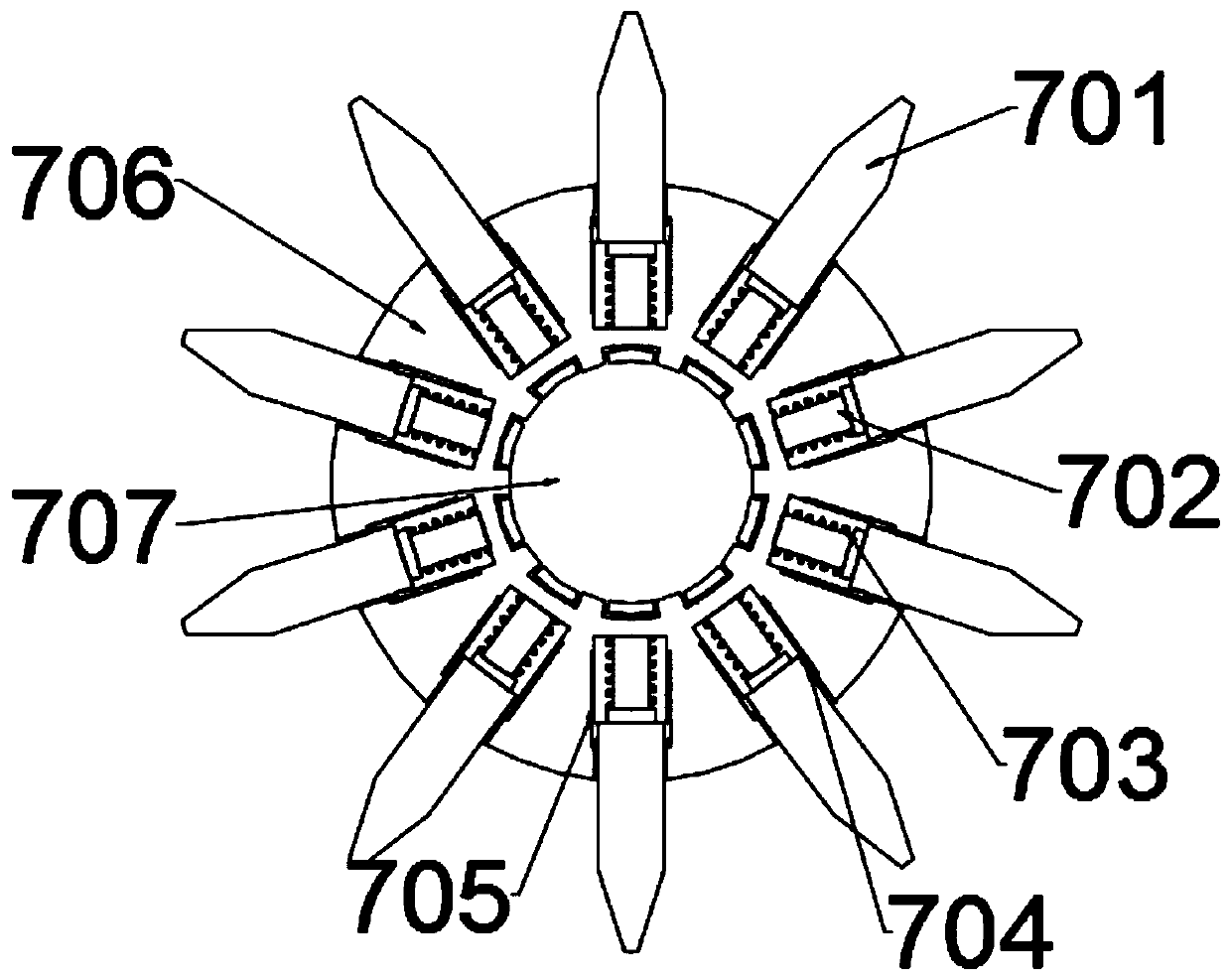

[0042] The soil is relatively compact after being used for a period of time, and it is easy to cause damage to the liquid injection head by inserting the liquid injection component into the soil alone. Therefore, in the specific implementation process of the present invention, another embodiment is proposed to improve the application. Specifically, The rotary tiller 4 is also included. The rotating shaft of the rotary tiller 4 is rotatably connected with the output shaft of the motor 14 installed on the inner wall of the casing 1 through a transmission belt 16. When the motor 14 rotates, the rotary tiller 4 is driven to rotate, thereby loosening the soil. deal with.

[0043] In order to effectively prevent soil from splashing into the inside of the casing 1 during the rotary tillage process, therefore, in the specific implementation of the present invention, a protective cover 15 fixedly connected to the casing 1 is provided above the rotary tiller 4.

[0044] In order to facilitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com