High-precision indenting machine for corrugated paper production

A high-precision, corrugated paper technology, applied in the direction of physical paper processing, mechanical processing/deformation, etc., can solve the problems of indentation of corrugated paper of various thicknesses, inability to adjust the indentation distance, unfavorable creasing work of the creasing roller, etc., to achieve The effect of improving the quality of finished product production and avoiding position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

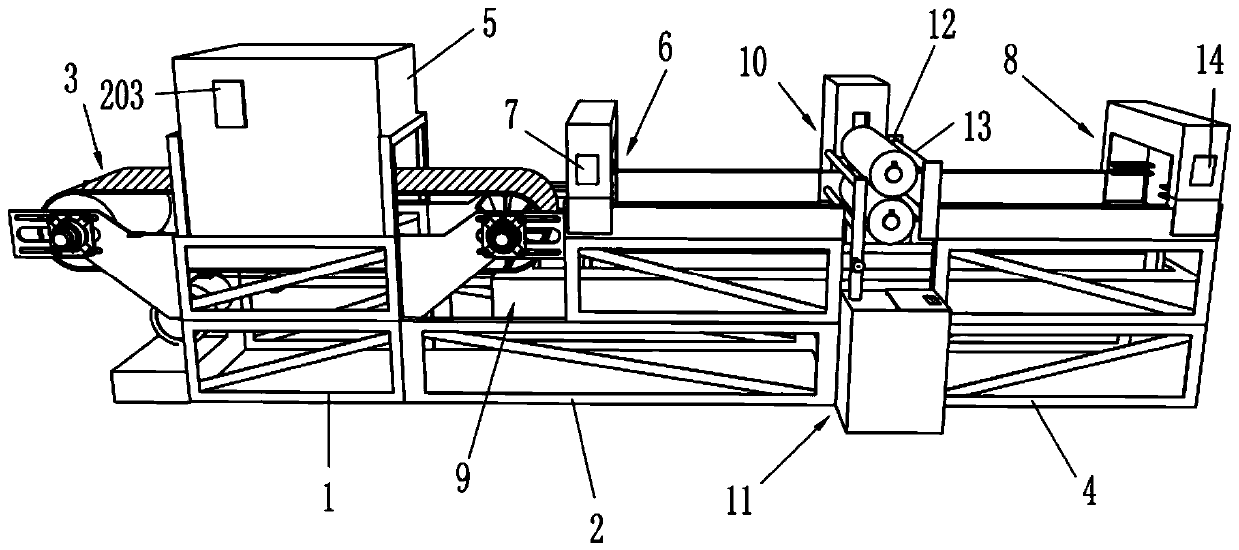

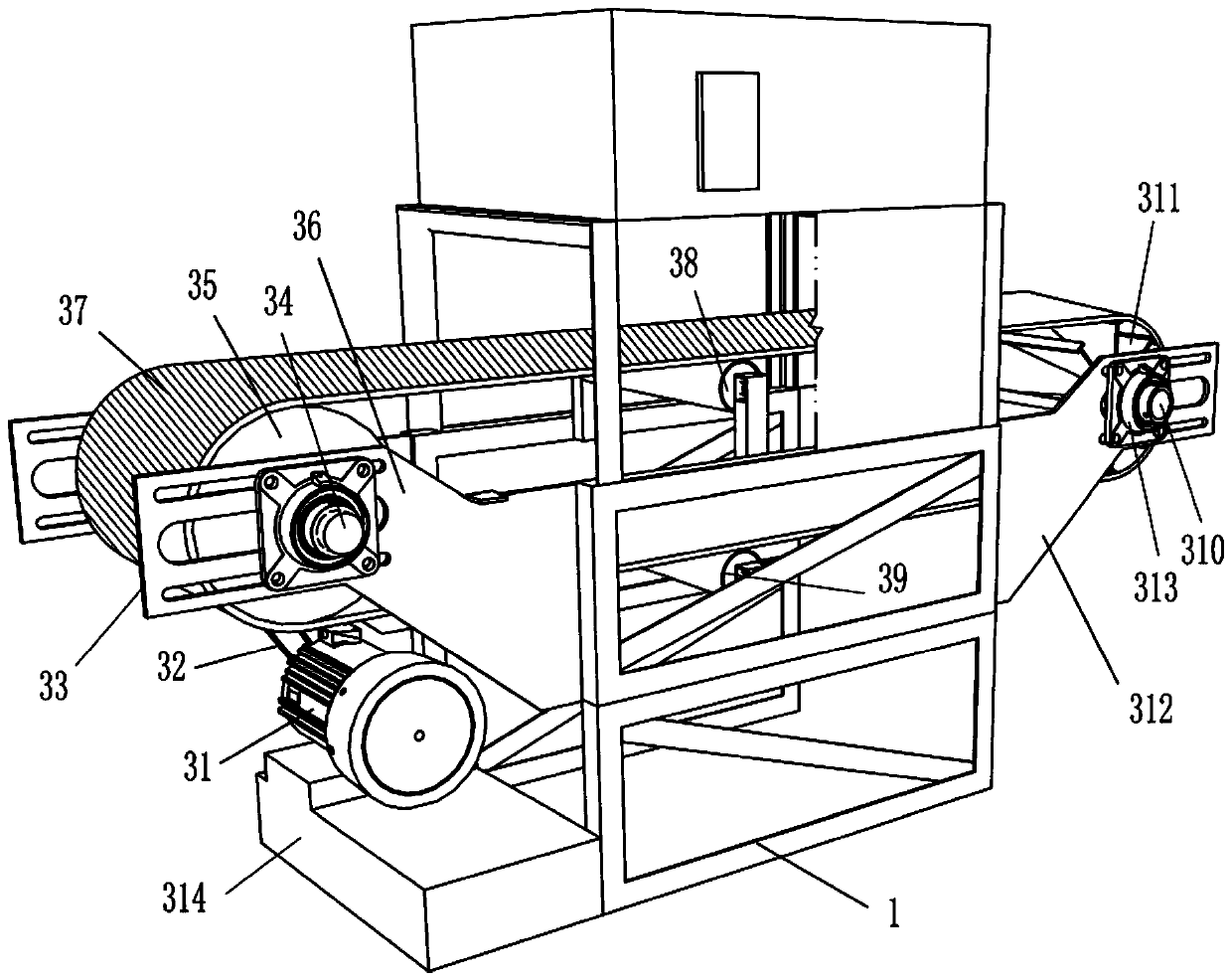

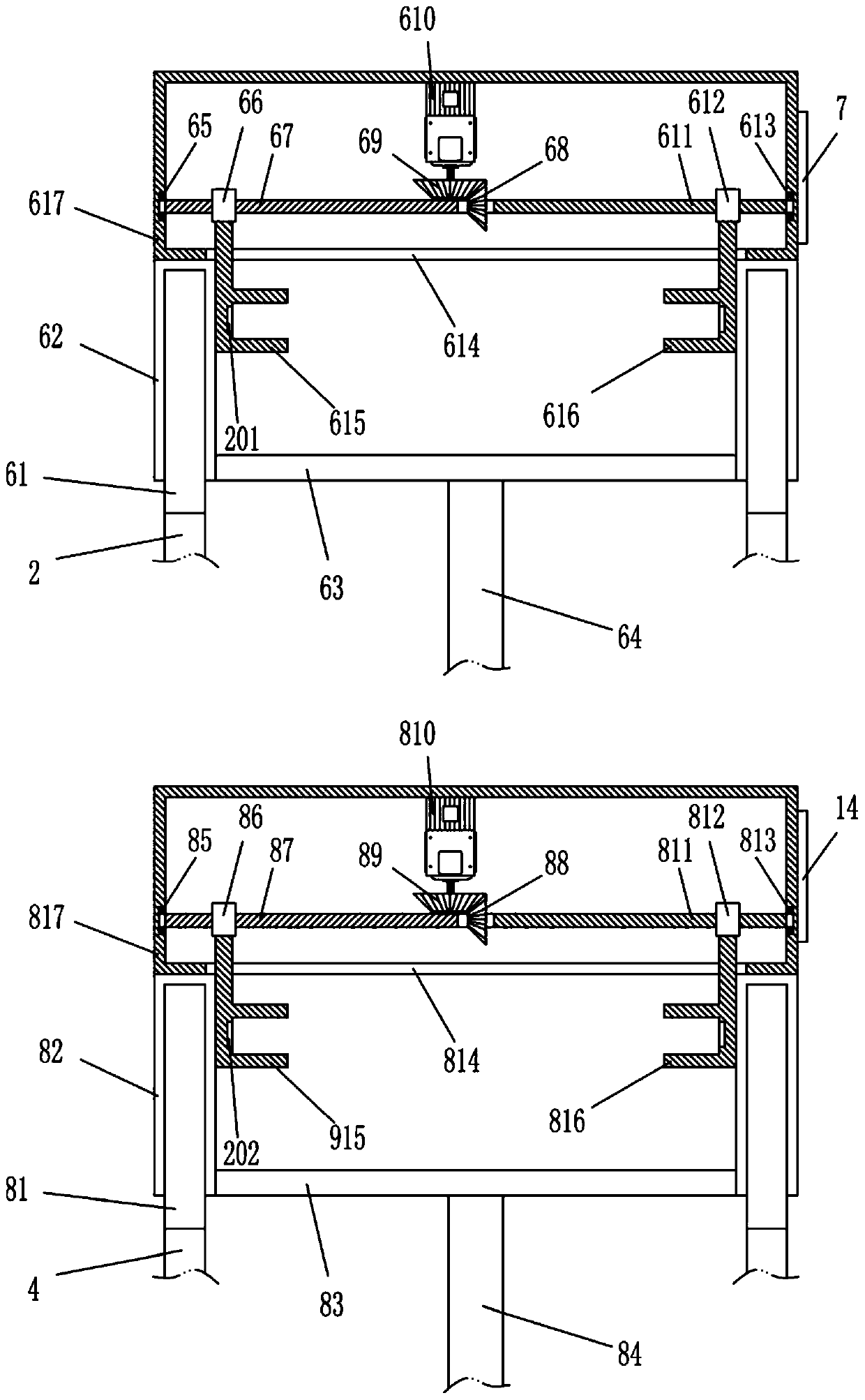

[0038] A high-precision creasing machine for corrugated paper production, such as Figure 1-8 As shown, it includes a first chassis 1, a second chassis 2, a transmission mechanism 3, a third chassis 4, a heating machine 5, a first clamping mechanism 6, a second clamping mechanism 8, a moving mechanism 9 and a press Marking mechanism 10; the first bottom frame 1, the second bottom frame 2, and the third bottom frame 4 are welded sequentially from left to right, the transmission mechanism 3 is installed on the first bottom frame 1, and the heating machine 5 is fixed on the first bottom frame through a bracket. The top of the frame 1, the heating machine 5 is located directly above the transmission mechanism 3, the first clamping mechanism 6 is installed on the top of the second chassis 2, the second clamping mechanism 8 is installed on the top of the third chassis 4, and the indentation mechanism 10 is installed on the Between the second chassis 2 and the third chassis 4, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com