Paper grooving cutter

A slotting knife and paper technology, applied in printing, rotary printing machines, printing machines, etc., can solve the problems of affecting the appearance, reducing the shelf life of paper, and the complex structure of the laminating machine, so as to achieve the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

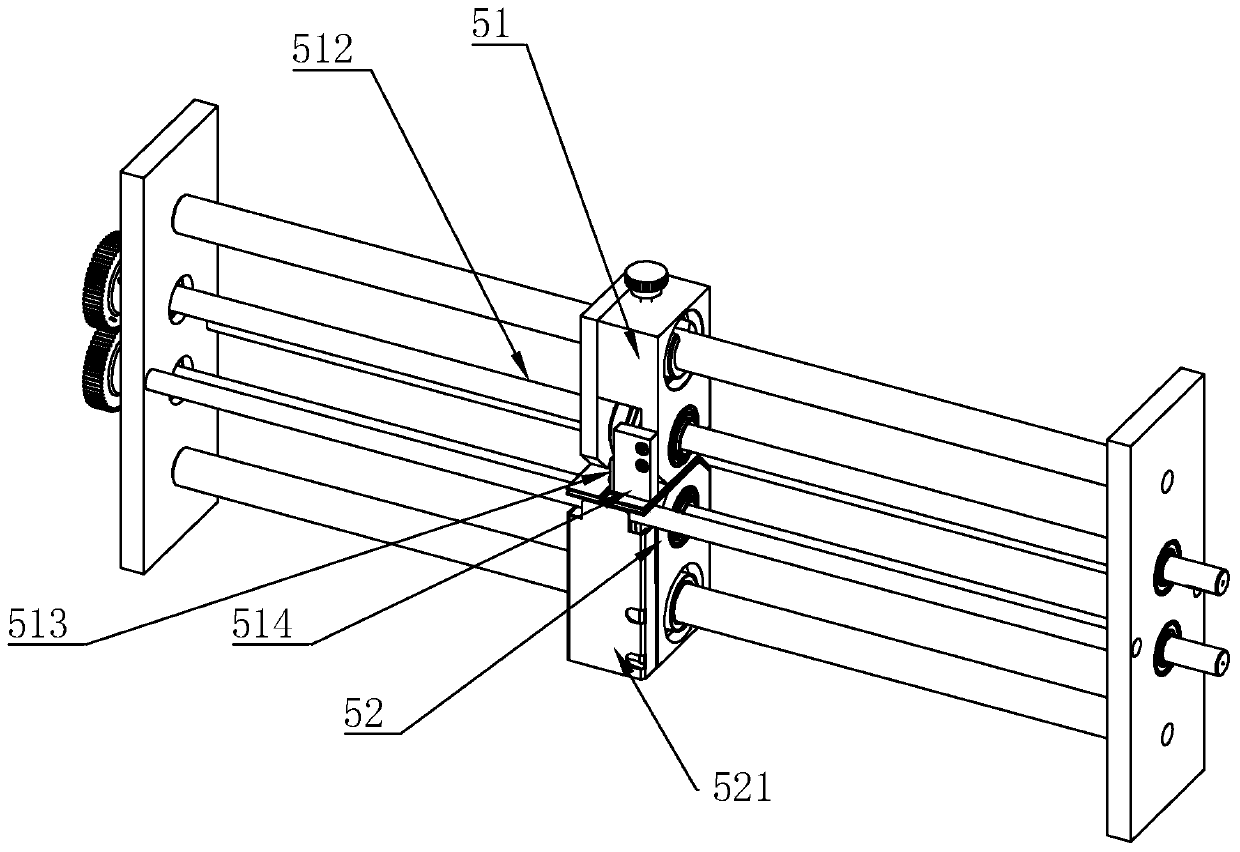

Method used

Image

Examples

specific Embodiment approach

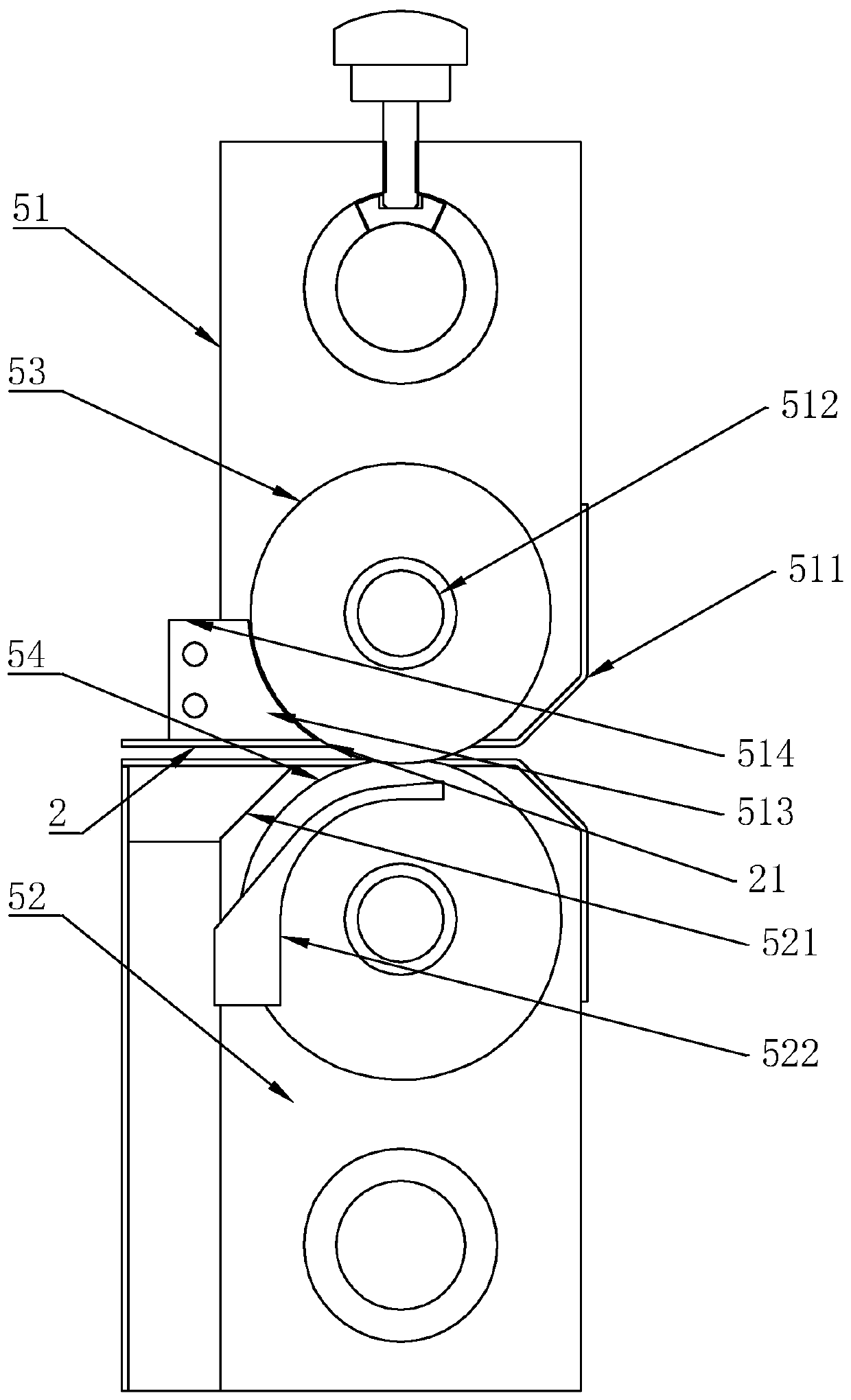

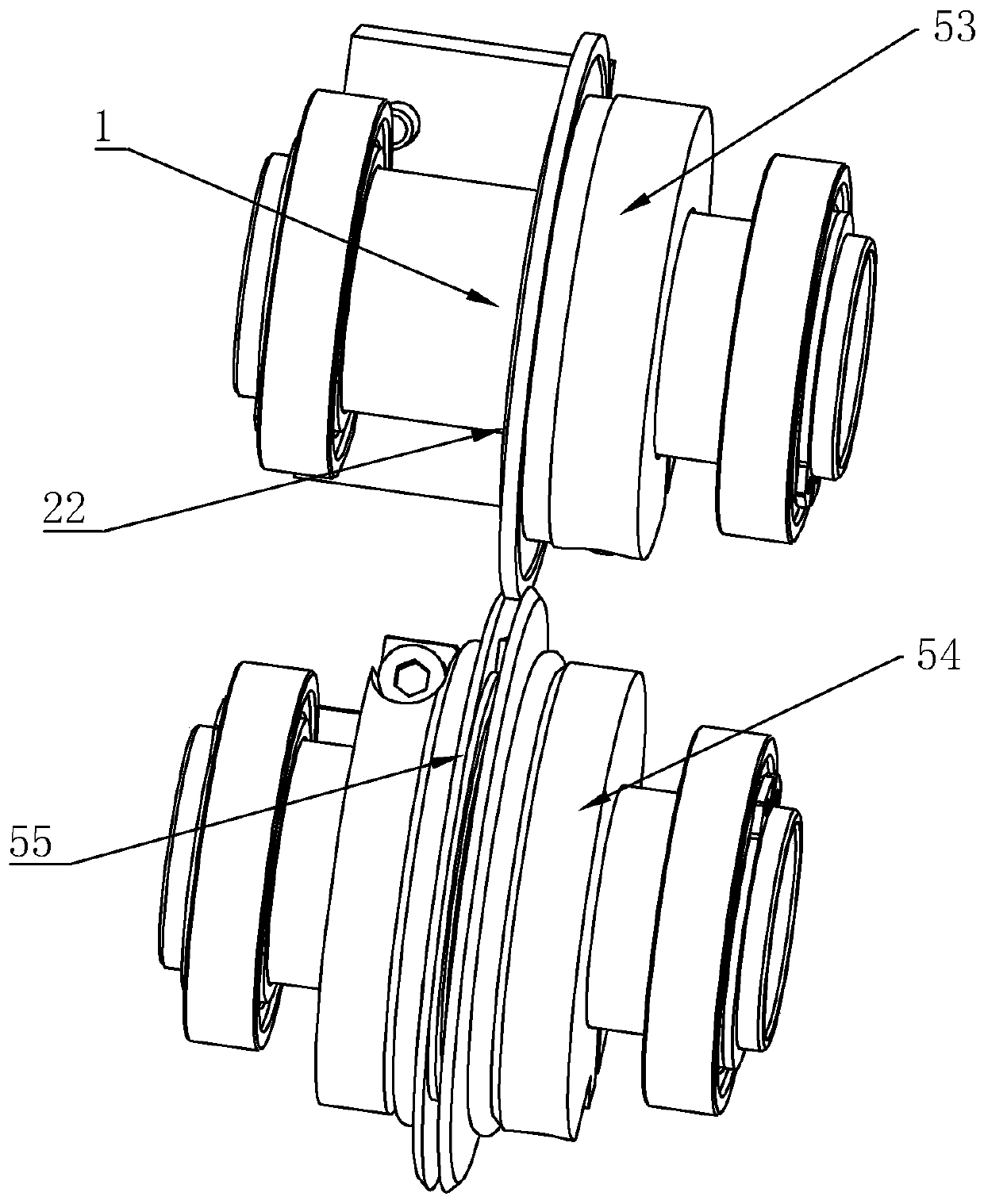

[0022] As an improved specific embodiment, the side of the lower knife seat 52 facing away from the paper guiding plate 511 is provided with a lower scraping seat 521 and a lower scraping plate 522, and the lower scraping plate 522 includes an introduction section and a combined section, so The introduction section is arranged below the slotting space, and the combination section is bent downward and is set opposite to the lower scraping seat 521 to form a scraping space, wherein the paper strips cut by the upper cutter 53 and the lower cutter 54 are hung on the introduction section, and then enter the scraping space through the introduction section, lead downward through the scraping space, and lead downward through the scraping space. After the paper is grooved, there will be a surplus paper strip, and the upper There is a hob structure between the cutter 53 and the lower cutter 54, so if the paper strip is not guided out in time, it is easy to cause the paper strip to be cau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com