Tethered underwater lifting platform

A lifting platform and mooring technology, which is used in underwater operation equipment, hull, ship construction, etc., can solve the problems of large horizontal drag force, high power consumption, intermittent time dimension and space dimension of sampled data, etc., and achieve the lifting speed. Stable, stable data collection, long stroke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

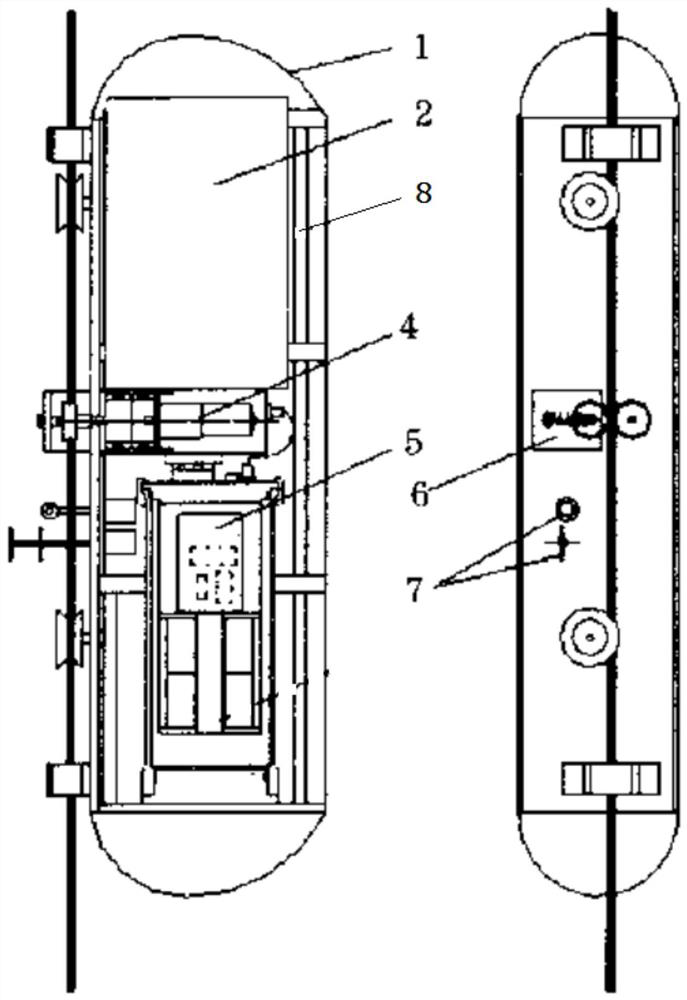

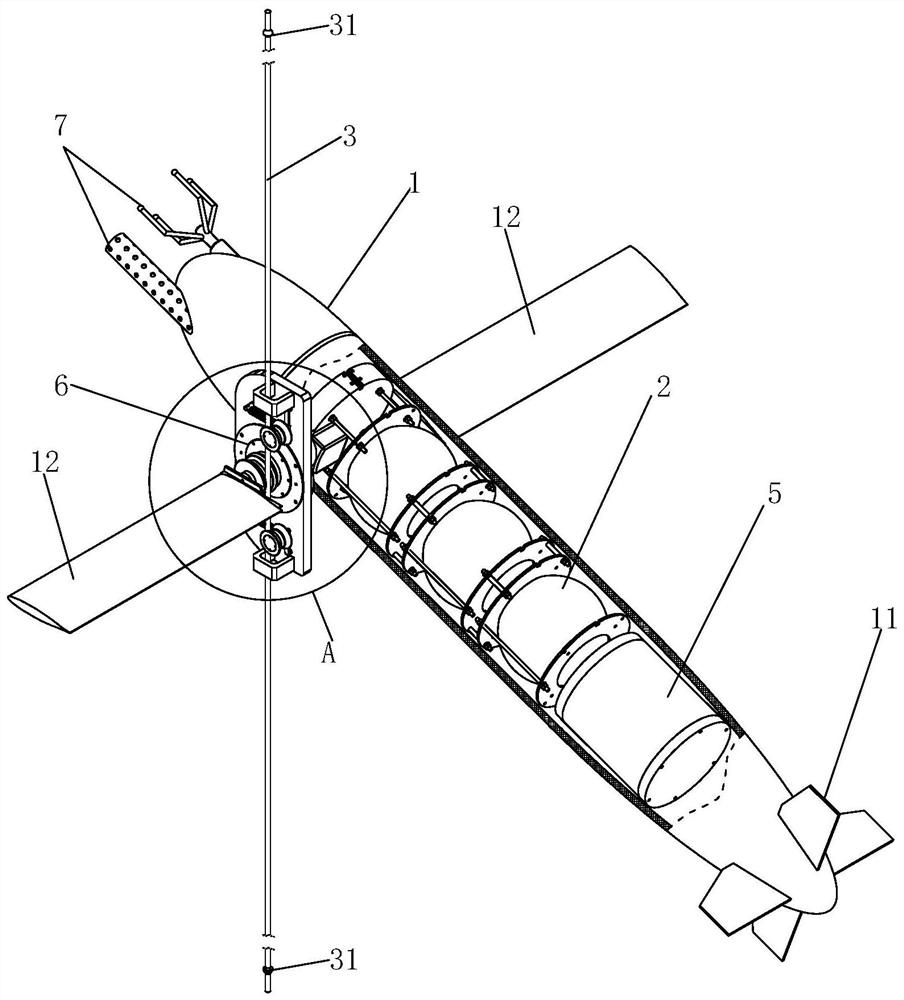

[0042] see figure 2 , image 3 As shown, the tethered underwater lifting platform includes a platform part 1, a driving part 4 and a moving part 6, wherein the driving part 4 is connected to the moving part 6 to drive the moving part 6 to move up and down along the mooring cable 3, and the platform part 1 It is rotatably connected with the moving part 6. When the moving part 6 moves up and down in the water along the mooring cable, it can drive the platform part 1 to rise and fall together. The platform part 1 is equipped with multiple types of sensors 7, and the sensors 7 perform circular and continuous profile measurements on the ocean during the lifting movement.

[0043] Further, the tethered underwater lifting platform also includes a tethered cable 3, and the two ends of the tethered cable 3 are connected with a universal swivel 31. The universal swivel 31 can realize the two-dimensional 360° rotation of the platform part 1, and the platform part 1 can rotate freely u...

Embodiment 2

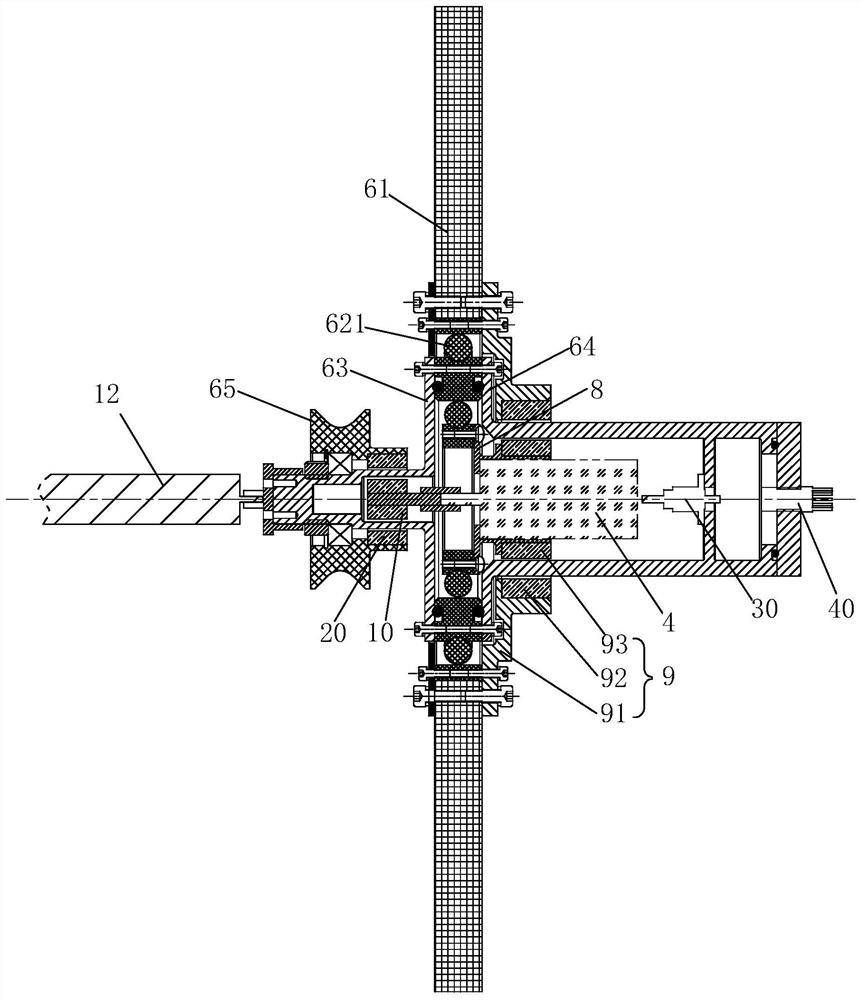

[0057] see Figure 6As shown, the difference from Embodiment 1 is that the rotational connection between the platform part 1 and the moving part 6 is realized through the second bearing 622, and the second bearing 622 has two layers of an outer ring and an inner ring. Specifically, a cylindrical protrusion 611 is provided on the right side of the vertical plate 61 , and the second bearing 622 is sleeved outside the cylindrical protrusion 611 . The vertical plate 61 is fixedly connected to the outer ring of the second bearing 622 , and the sealing housing 64 is fixedly connected to the inner ring of the second bearing 622 , so as to realize the rotational connection between the platform part 1 and the moving part 6 .

[0058] Specifically, the driving part 4 is fixedly connected to the vertical plate 61 through the flange 8, so that the driving of the driving wheel 65 by the driving part 4 and the rotation of the platform part 1 relative to the moving part 6 do not interfere wi...

Embodiment 3

[0060] see Figure 7 As shown, the difference from Embodiment 2 is that the right side surface of the vertical plate 61 is provided with an annular groove 612, the left end of the sealing housing 64 is inserted into the annular groove 612, and the sealing housing 64 is provided with a protrusion 641 , the vertical plate 61 is provided with an annular groove 613 that cooperates with the protrusion 641, and the annular groove 613 cooperates with the protrusion 641, which can limit the horizontal movement of the sealing shell 64 and realize the contact between the platform part 1 and the moving part 6 Turn to connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com