Low energy consumption rapid detection and deicing method based on ultrasonic waves

An ultrasonic and low energy consumption technology, which is applied in deicing devices, aircraft parts, transportation and packaging, etc., can solve the problems of poor deicing effect, high energy consumption, and low durability, and achieve high deicing efficiency and overall energy consumption Low, good deicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

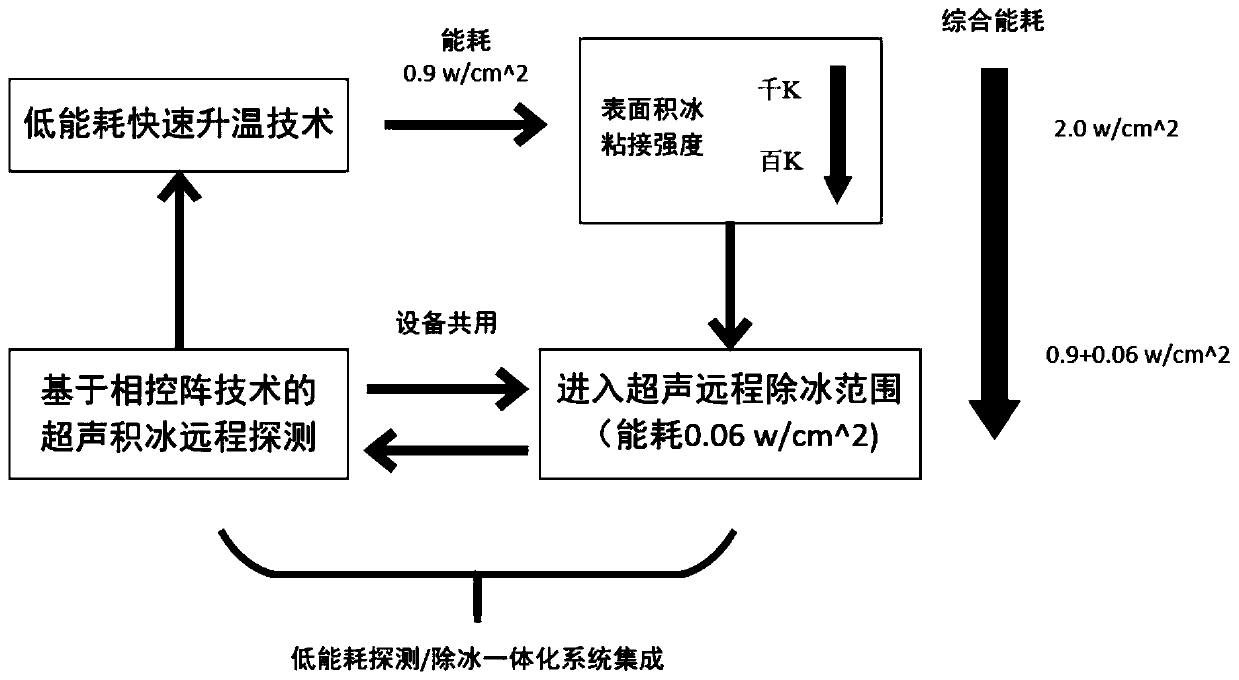

[0029] figure 1 It is a flowchart of a low-energy fast detection and deicing method based on ultrasonic waves;

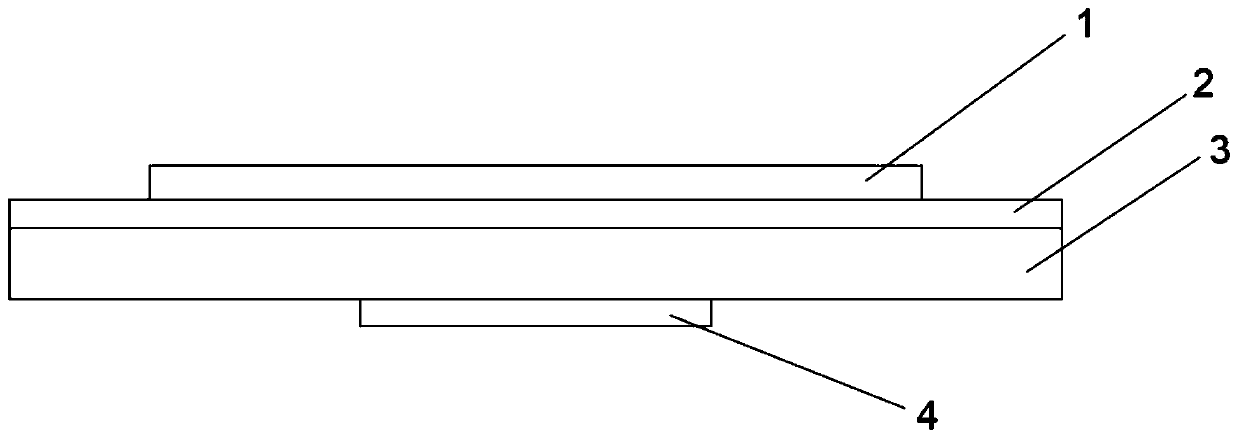

[0030] figure 2 It is a schematic diagram of a low-energy fast detection and de-icing device based on ultrasonic waves;

[0031] Description of the drawings: icing 1 , electric heating device 2 , structured surface 3 , ultrasonic exciter 4 .

[0032] The invention provides a low-energy fast detection / de-icing method based on ultrasonic waves, the specific steps include: figure 1 The three parts shown:

[0033] 1. The ultrasonic exciter monitors the ice accumulation on the surface of the structure in real time.

[0034] The ultrasonic exciter is made of piezoelectric material and can be used as an exciter and a sensor at the same time. The ultrasonic exciter is evenly distributed on the inner surface of the structure at a certain distance. Some devices are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com