Discharge bottle

A material bottle and bottle body technology, which is applied in the field of material bottles, can solve the problems of not being moisture-proof and unable to accurately batch ingredients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

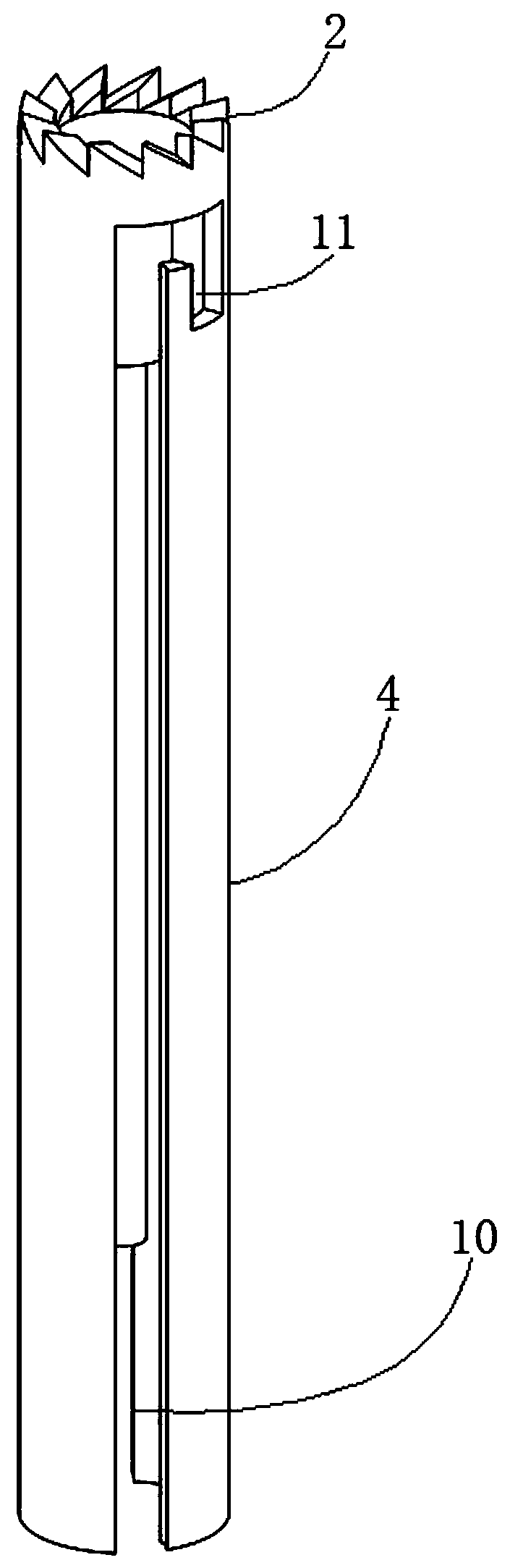

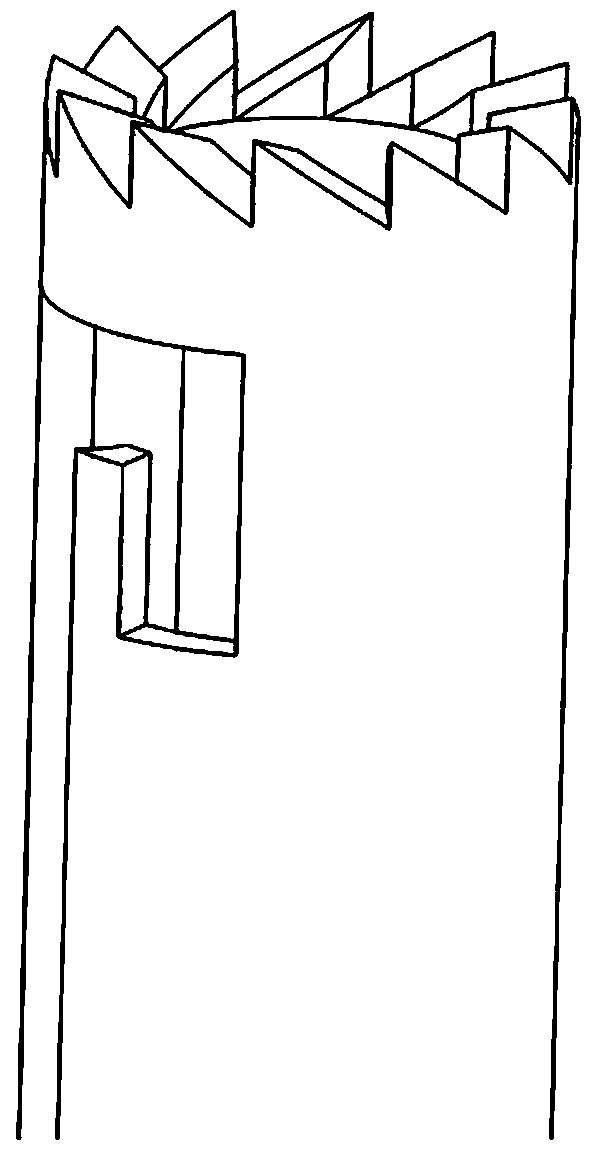

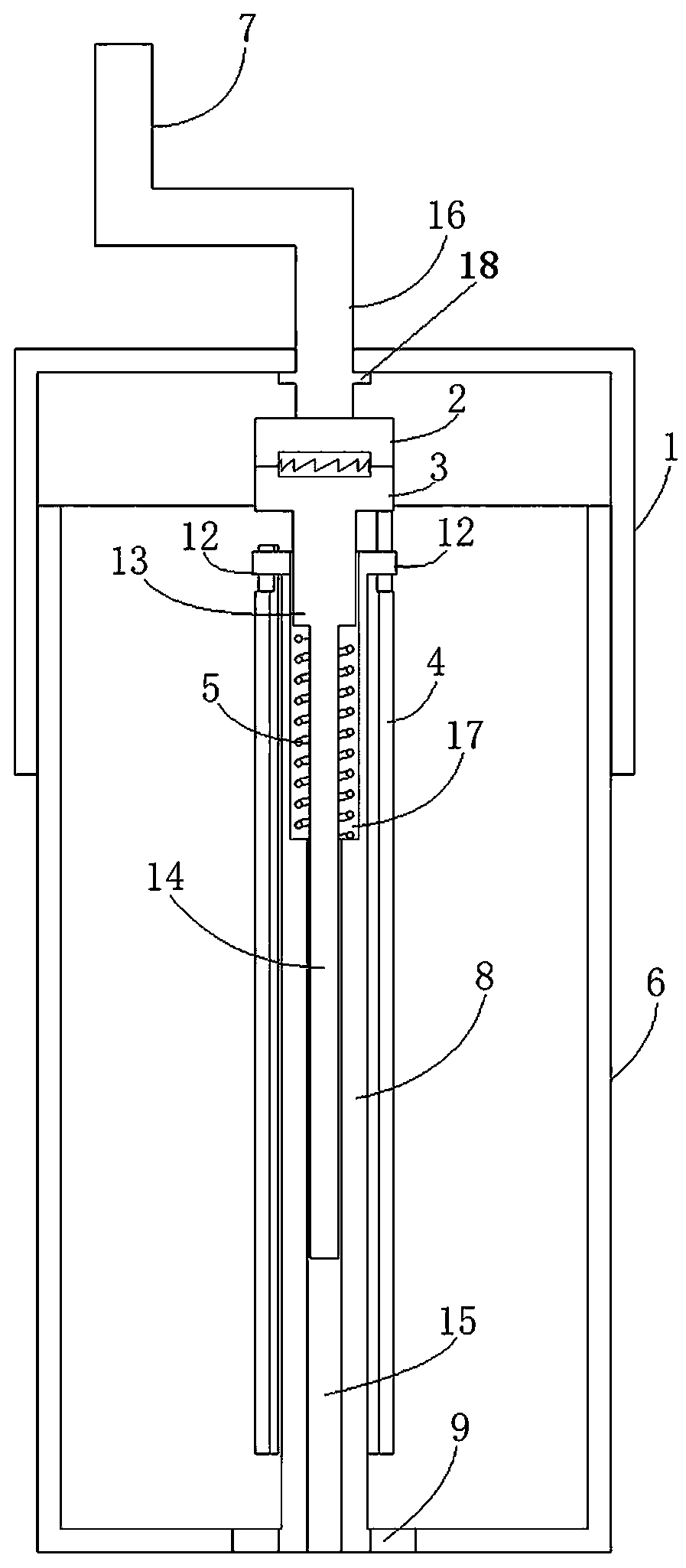

[0013] The upper end of the bottle body 6 of the discharge bottle is threadedly connected with the bottle cap 1, the bottom center of the bottle body 6 is fixedly connected with the pillar 8, and the bottom of the bottle body 6 has a discharge hole 9 along the periphery of the pillar 8, and the rotating shaft 16 passes through the bottle cap The upper end surface of 1 is fixedly connected with the upper vibrating tooth 2, the rotating shaft 16 is fixedly connected with the handle 7 or is connected with the motor transmission, the rotating shaft 16 has a positioning part 18 in contact with the bottom of the bottle cap 1, and the upper and lower vibrating teeth have equal radii and mesh with each other. ring teeth, the lower vibrating tooth 3 is fixedly connected with the upper end of the cylinder 13 at the upper end of the vibrating rod 14 and the upper end of the circular sleeve 4, and the upper ends of the symmetrical two axial grooves 10 on the cylindrical surface of the circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com