Online slitting equipment for film

A film and equipment technology, applied in the field of film online slitting equipment, can solve problems such as low work efficiency, high shutdown rate, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

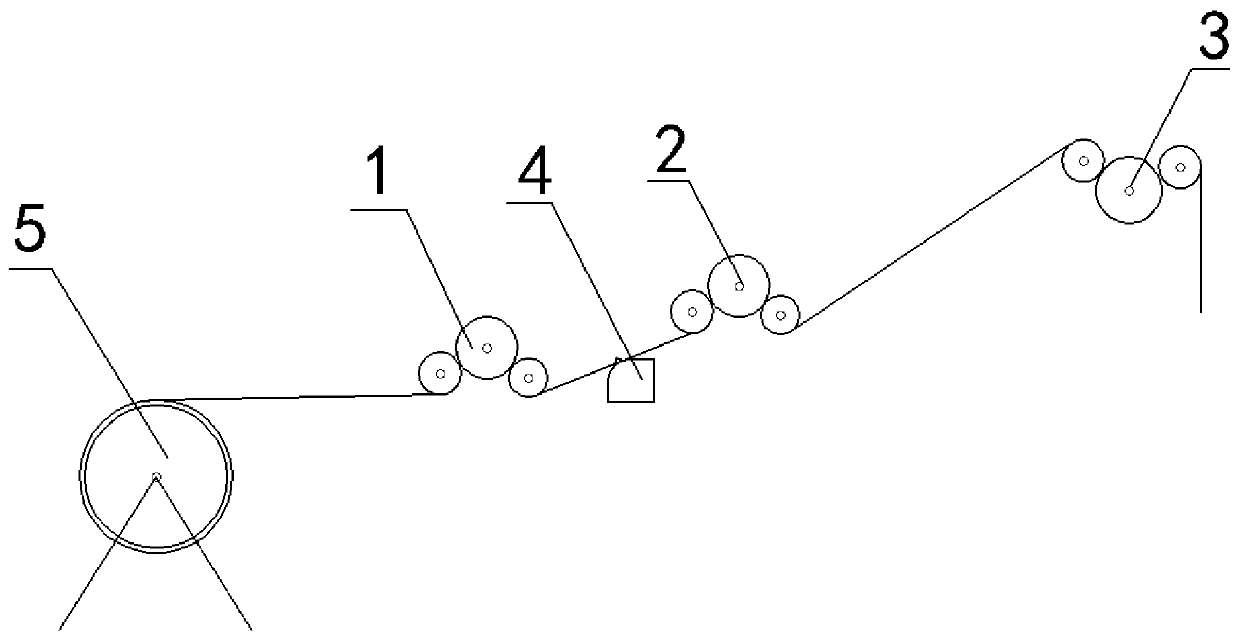

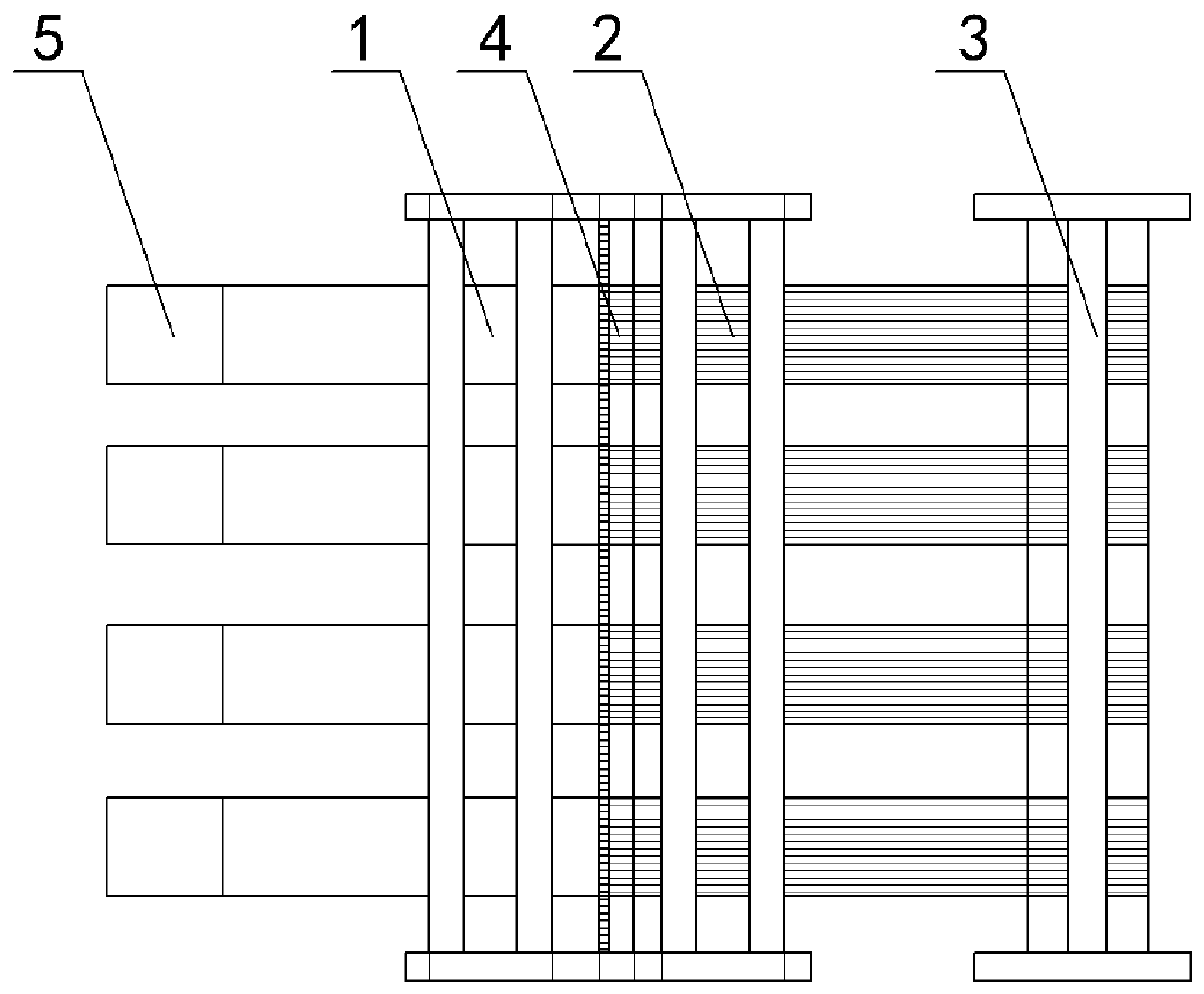

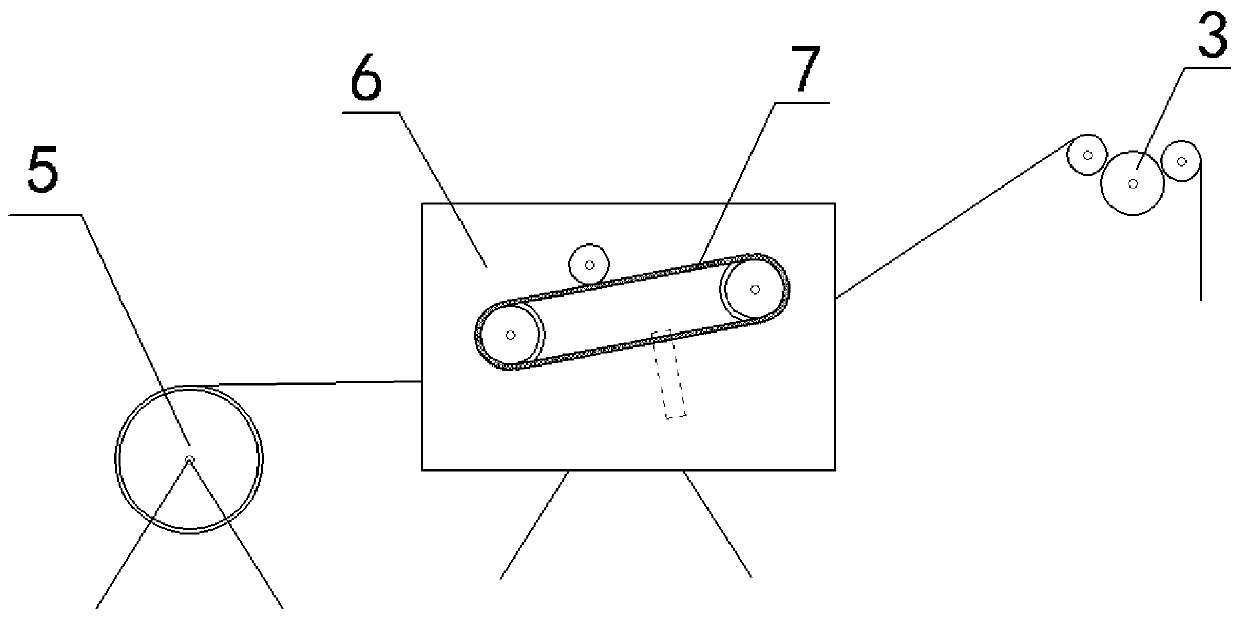

[0032] This specific embodiment provides an online film slitting device, which can automatically slit film raw materials into film strips, and automatically feed the film strips after slitting into the warp knitting machine, eliminating the need for film The process of winding the strips on the I-shaped disc and manually putting the I-shaped disc on the rack greatly improves the work efficiency and reduces the labor intensity. Moreover, the film strips fed to the warp knitting machine have better flatness and are effective. It is conducive to improving the quality and efficiency of warp knitting, and effectively solves the problems of high labor intensity, poor flatness of warp knitting products, high shutdown rate and low work efficiency in the existing film warp knitting process.

[0033] In order to make the purpose, technical solution and advantages of the present invention clearer, the technical solution of the present invention will be described in detail below. Apparent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com