A rolling method of large single weight and wide molybdenum strip for sputtering target

A technology of sputtering target material and large unit weight, which is applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of small average grain size, low surface flatness, uneven density, etc., and achieve Effects of small grain size, high surface flatness, and uniformity of thickness distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

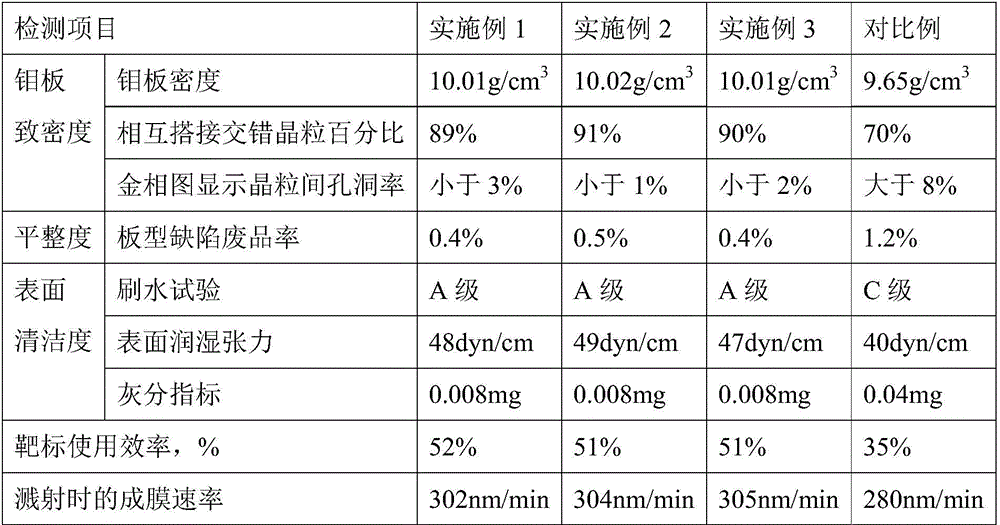

Examples

Embodiment 1

[0033] The sputtering target material of the present embodiment is used the rolling method of large unit weight wide width molybdenum strip, comprises the following steps:

[0034] 1) Blank opening:

[0035] Take powder metallurgy sintered molybdenum slab, size 87mm×550mm×450mm, density 9.6g / cm 3 The unit weight is about 206kg; the powder metallurgy sintered molybdenum slab includes the following components in mass percentage: Si 0.003%, Ca 0.002%, Mg0.002%, P 0.001%, C 0.02%, O 0.003%, N 0.003% , the balance is Mo;

[0036] Put the molybdenum slab into a 450kw medium-frequency induction heating furnace, and heat it to 1490°C under a hydrogen protective atmosphere for preheating. The preheating time is 60 minutes;

[0037] Put the preheated molybdenum slab on the ф800mm×1200mm two-roller irreversible hot rolling mill, and carry out the second fire six-pass hot rolling at the rolling speed of 50m / min; the used rolls are preheated online before rolling, preheating The tempera...

Embodiment 2

[0062] The sputtering target material of the present embodiment is used the rolling method of large unit weight wide width molybdenum strip, comprises the following steps:

[0063] 1) Blank opening:

[0064] Take powder metallurgy sintered molybdenum slab, size 87mm×550mm×450mm, density 9.6g / cm 3 The unit weight is about 206kg; the powder metallurgy sintered molybdenum slab includes the following components in mass percentage: Si 0.003%, Ca 0.002%, Mg0.002%, P 0.001%, C 0.02%, O 0.003%, N 0.003% , the balance is Mo;

[0065] Put the molybdenum slab into a 450kw medium-frequency induction heating furnace, and heat it to 1485°C under a hydrogen protective atmosphere for preheating, and the preheating time is 61 minutes;

[0066] Put the preheated molybdenum slab on the ф800mm×1200mm two-roller irreversible hot rolling mill, and carry out the second fire six-pass hot rolling at the rolling speed of 48m / min; the used rolls are preheated online before rolling, preheating The tem...

Embodiment 3

[0091] The sputtering target material of the present embodiment is used the rolling method of large unit weight wide width molybdenum strip, comprises the following steps:

[0092] 1) Blank opening:

[0093] Take powder metallurgy sintered molybdenum slab, size 87mm×550mm×450mm, density 9.6g / cm 3 The unit weight is about 206kg; the powder metallurgy sintered molybdenum slab includes the following components in mass percentage: Si 0.003%, Ca 0.002%, Mg0.002%, P 0.001%, C 0.02%, O 0.003%, N 0.003% , the balance is Mo;

[0094] Put the molybdenum slab into a 450kw medium-frequency induction heating furnace, and heat it to 1495°C under a hydrogen protective atmosphere for preheating. The preheating time is 59 minutes;

[0095] Put the preheated molybdenum slab on the ф800mm×1200mm two-roller irreversible hot rolling mill, and carry out the second fire six-pass hot rolling at the rolling speed of 52m / min; The temperature is 305°C;

[0096] Before the molybdenum slab enters the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com